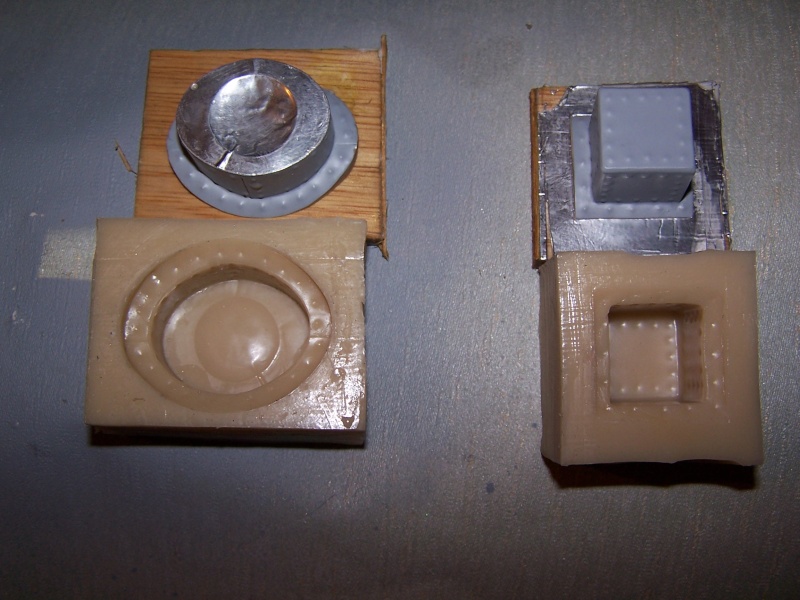

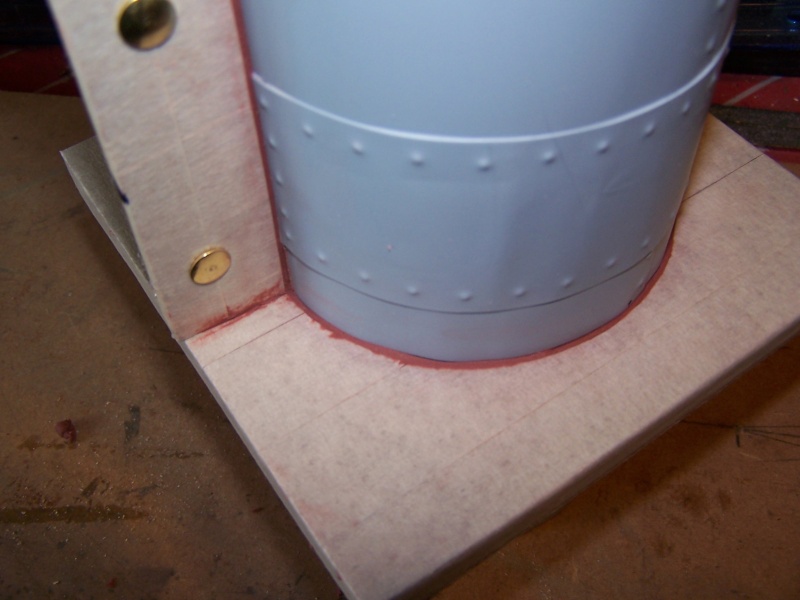

Once the sides are removed I gently pull the moulds free of the patterns.

In total there are 7 users online :: 1 Registered, 0 Hidden and 6 Guests :: 1 Bot

Most users ever online was 180 on Tue Nov 05, 2019 6:03 am

Our users have posted a total of 12449 messages in 1981 subjects

We have 1010 registered users

The newest registered user is Chris Shelley

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER Re: CSS PIONEER

Re: CSS PIONEER Re: CSS PIONEER

Re: CSS PIONEER Re: CSS PIONEER

Re: CSS PIONEER Re: CSS PIONEER

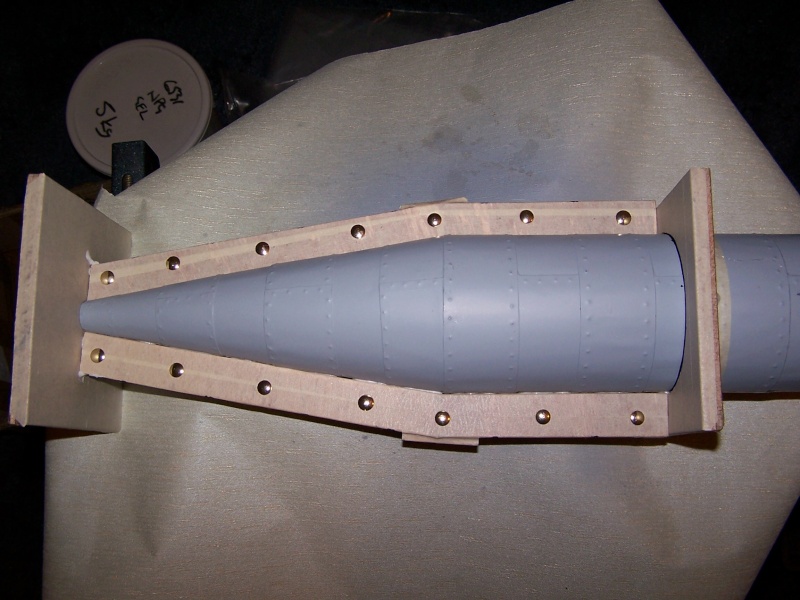

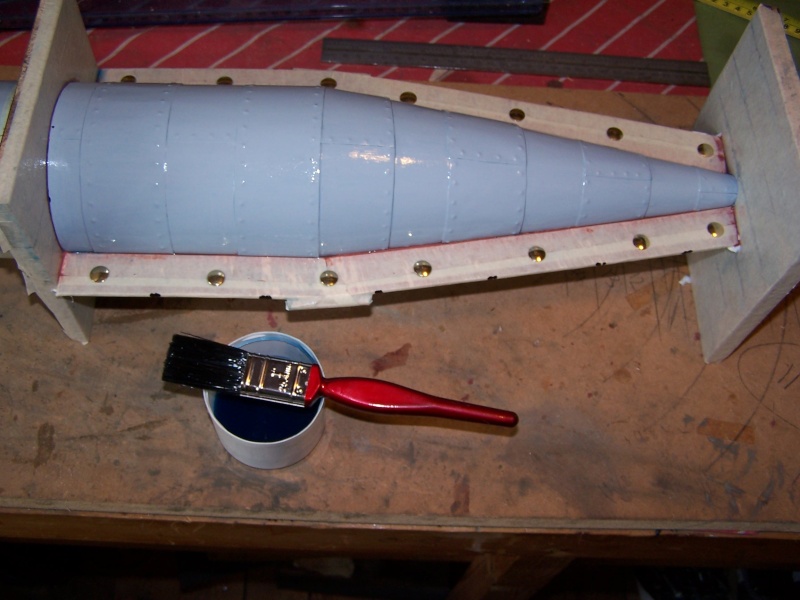

Re: CSS PIONEER CSS PIONEER MAIN HULL MOULD

CSS PIONEER MAIN HULL MOULD

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

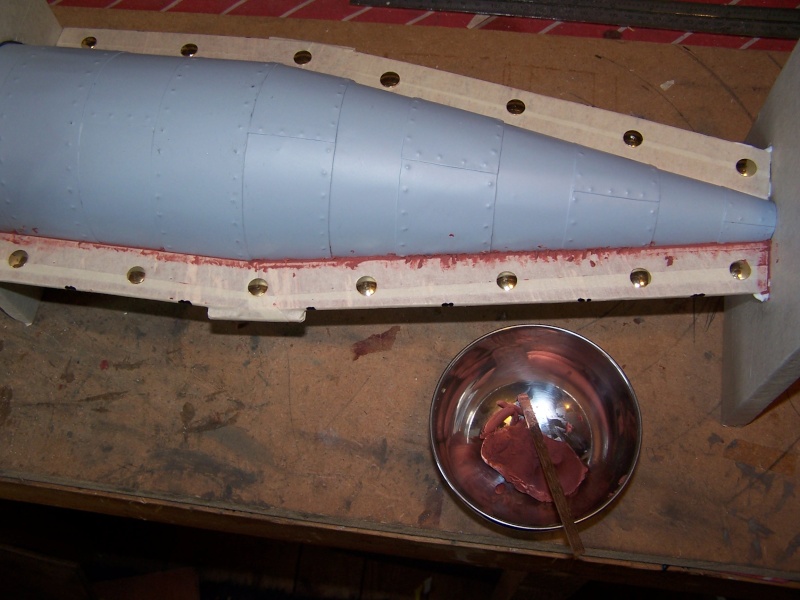

Re: CSS PIONEER CSS PIONEER, HULL

CSS PIONEER, HULL Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

Re: CSS PIONEER

» Modulated electric fields for submarine communication in a "heads up" from Harry!

» 868/915 Mhz as a viable frequency for submarines.

» Laser cut Robbe U47 conversion

» ExpressLRS - 868/915 Mhz equipment

» Information on camouflage patterns for German seahund

» WW2 mini sub build

» Not the hobby I expected :)

» Sheerline gasket material