cat Sun Oct 01, 2023 5:50 pm

cat Sun Oct 01, 2023 5:50 pm

Still very learning lathe, I've done a bit of facing, turning and a little bit of knurling, but I've not done a thread yet and an experiment in cutting an o-ring groove failed spectacularly. The mystery plastic I was messing with didn't want to cut a nice flat bottom in the groove despite the same tool turning an acceptable outside diameter. It's all learning and I will get round to casting some endcaps and giving grooving a go on resin in due course.

Meanwhile I've been mucking about with some actual sub building and radio fettling.

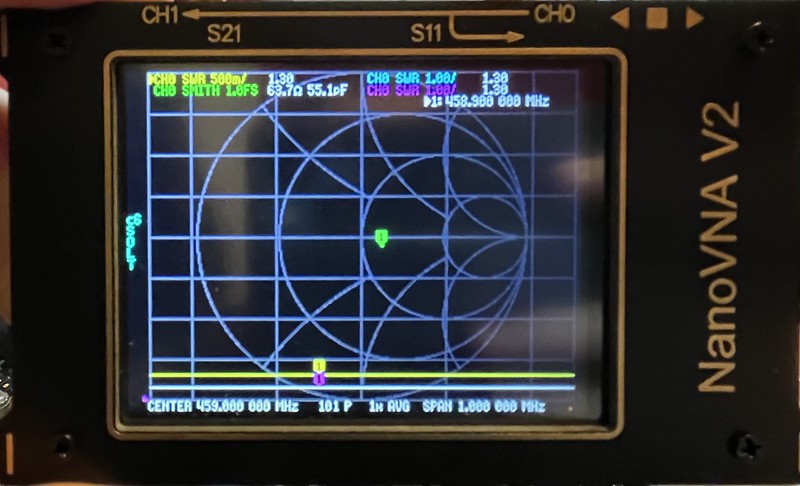

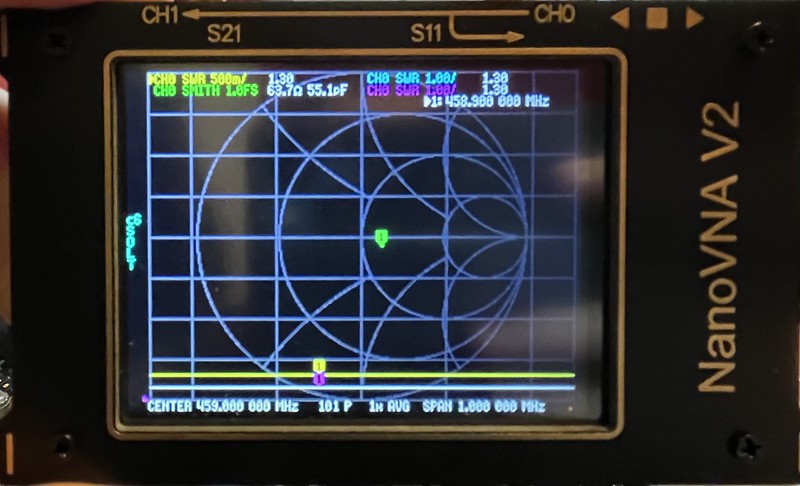

One of my good friends loaned me one of whatever these things are and I've been batting my SWR numbers on antennas as close to 1 as I can get for a center frequency of 459Mhz (band being 458.5 - 459.5 so sayeth ofcom

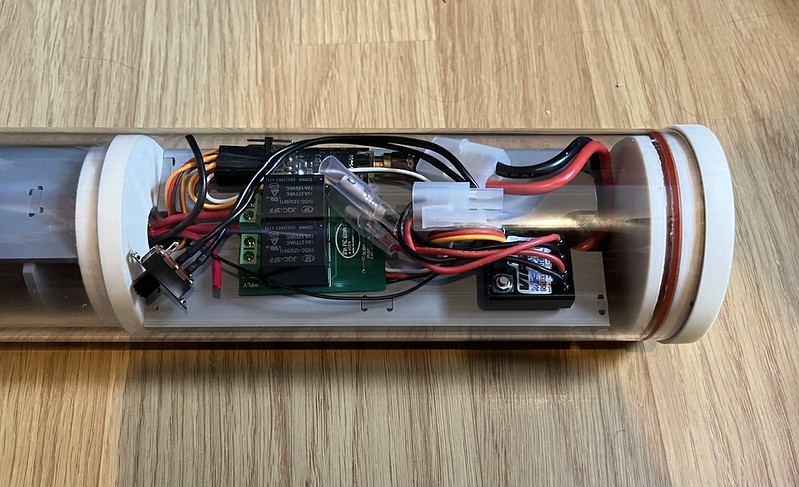

Submarine wise, I've cut holes in the bulkheads for air and water to circulate, glued in the rubber band rings that support the tube center it, I've got the rear prop fin things installed with the prop bearing inside, the cylinder end prop support and control surface control arm whatsit is glued in and shimmed so that the prop shaft turns freely.

I've drilled all the holes for the control surfaces at the back end of the sub and I'm working out how the control wires need to be bent, at the moment they want to bind for down dive plane so some bending must be required to make them sit and run right, I might drag the thing down to my boat club to get some practical advice from real life model makers.

Still loads to do, but the list of stuff is getting gradually shorter!

» Futaba -868/915mhz equipment

» Darnell type 21 submarine, need some help

» Robbe Seawolf V2

» bladder bags

» WW2 mini sub build

» Peral Submarine of 1888

» U-Boat R/C?

» Cheap Arduino Auto leveler