david f wrote:Lovely work Bart!

I was interested to hear about your conclusion that the sub could not float.

This happens - I believe it happened to a 1:1 Spanish sub recently!

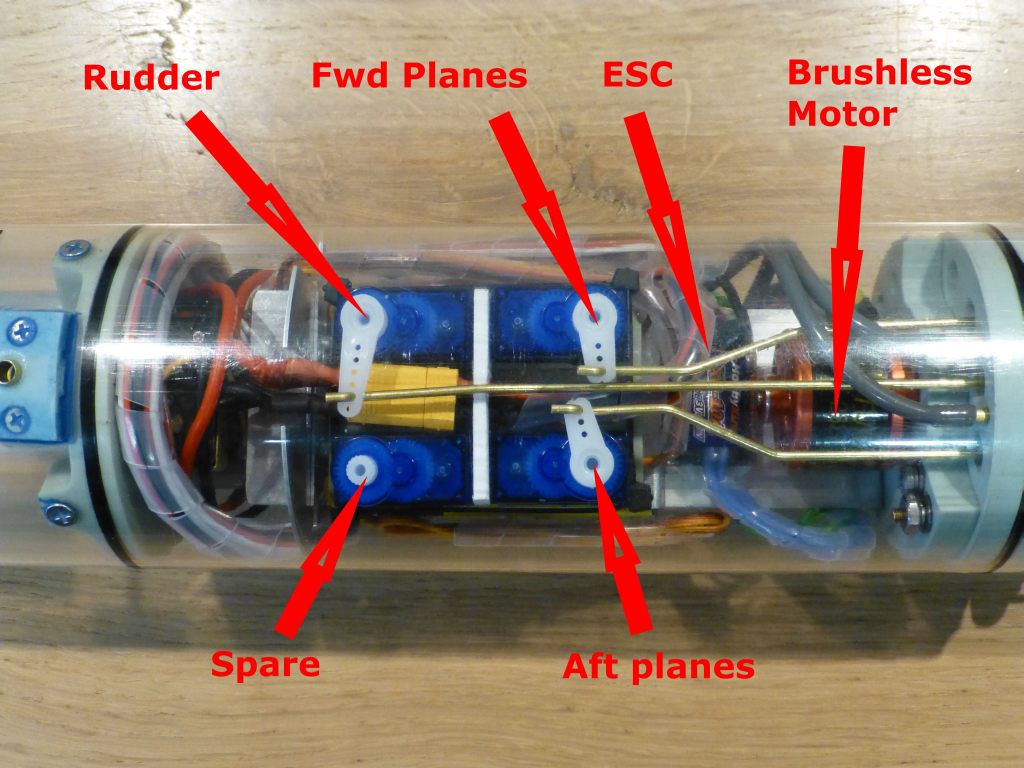

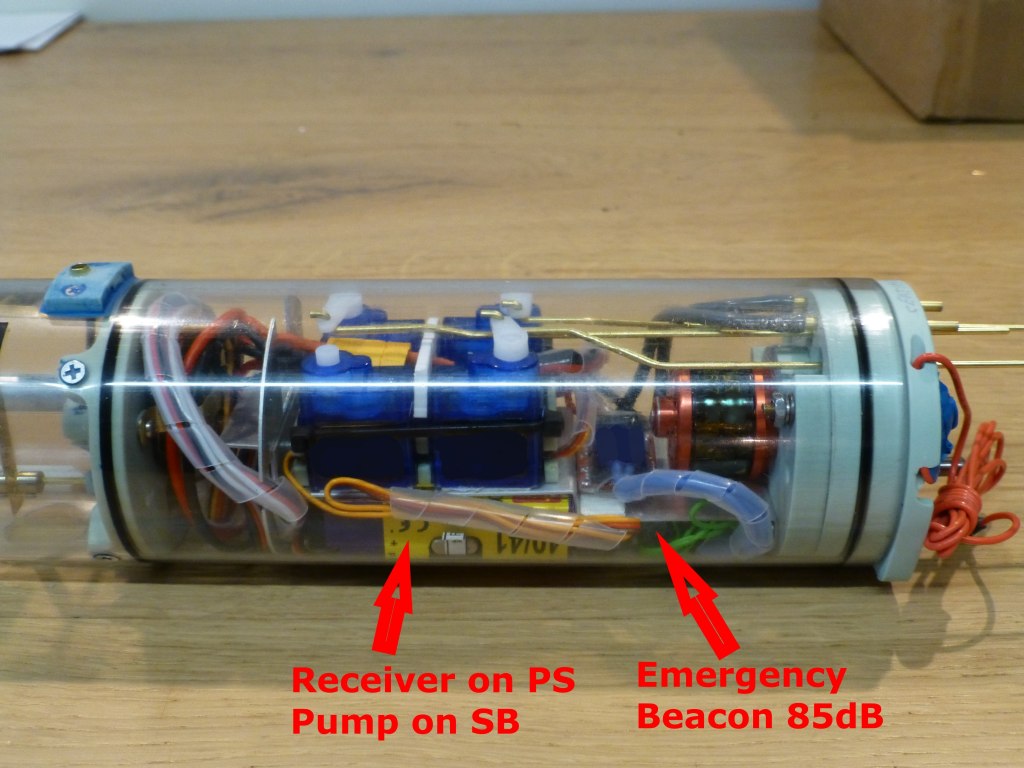

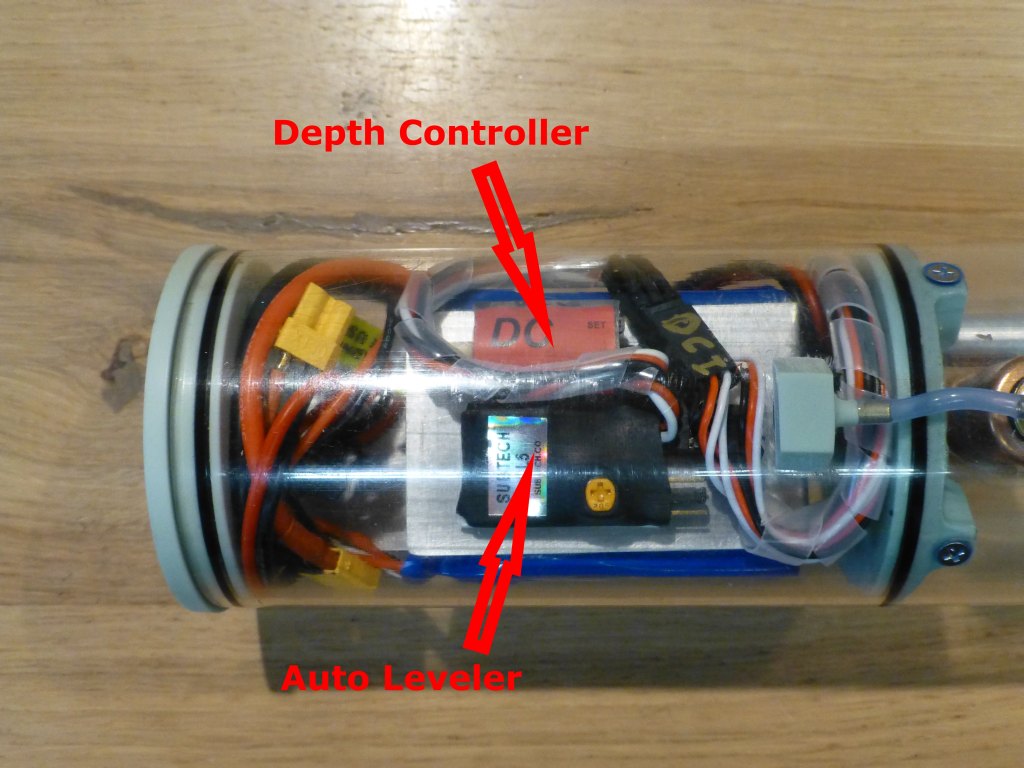

With small subs you can easily run out of buoyancy. I think that can justify a dry-hull concept rather than a WTC.

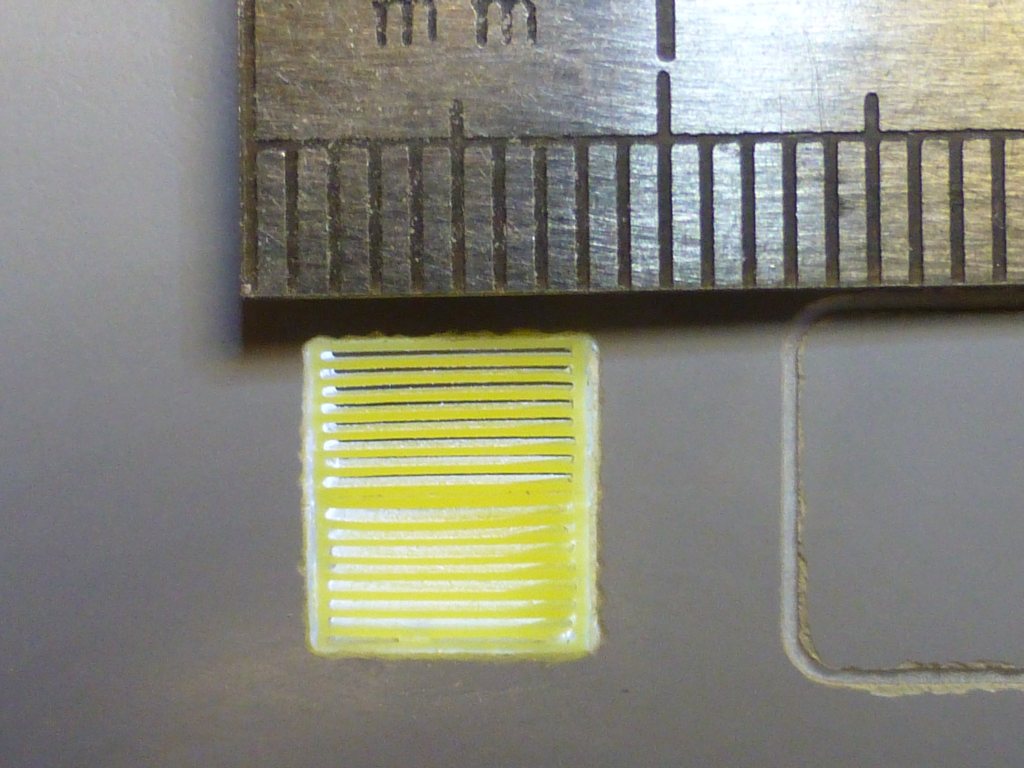

I was impressed by your use of plexiglass (perspex). I found that the darned stuff used to fracture too much and so I started using polycarbonate. Do you use a particular grade or mix of plexiglass perhaps?

David

Thks David,

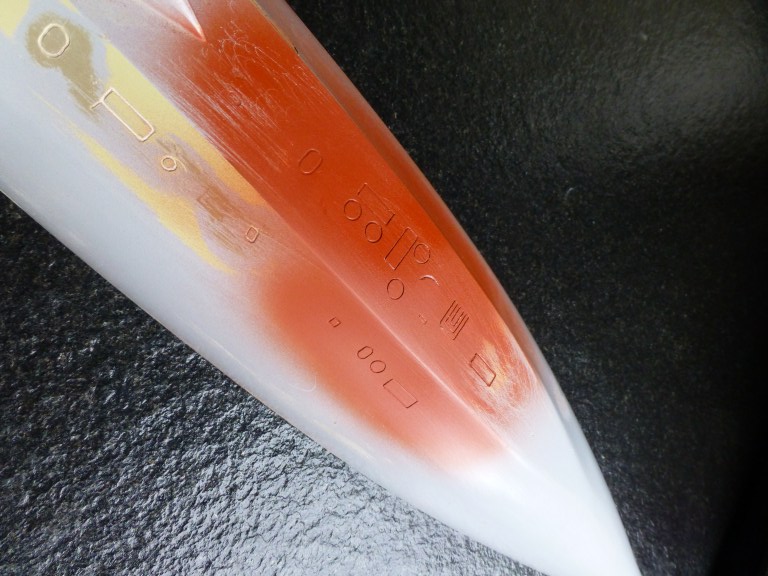

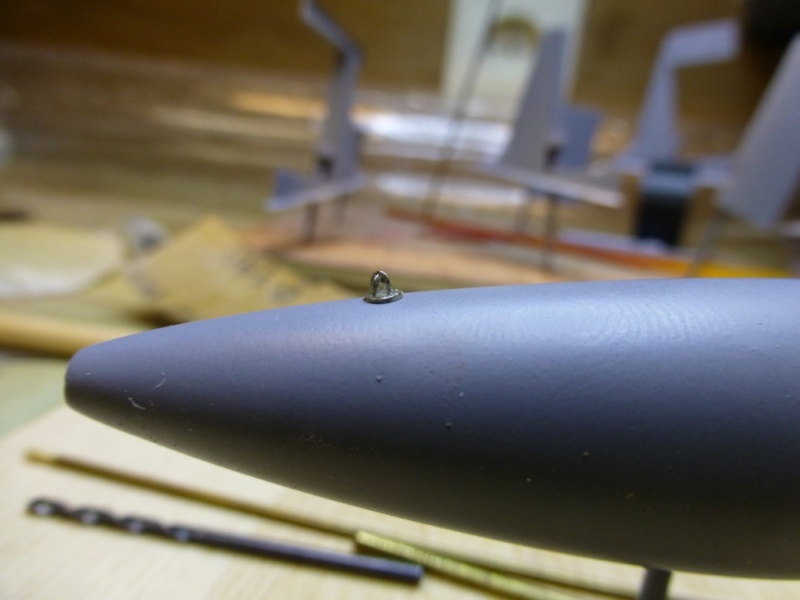

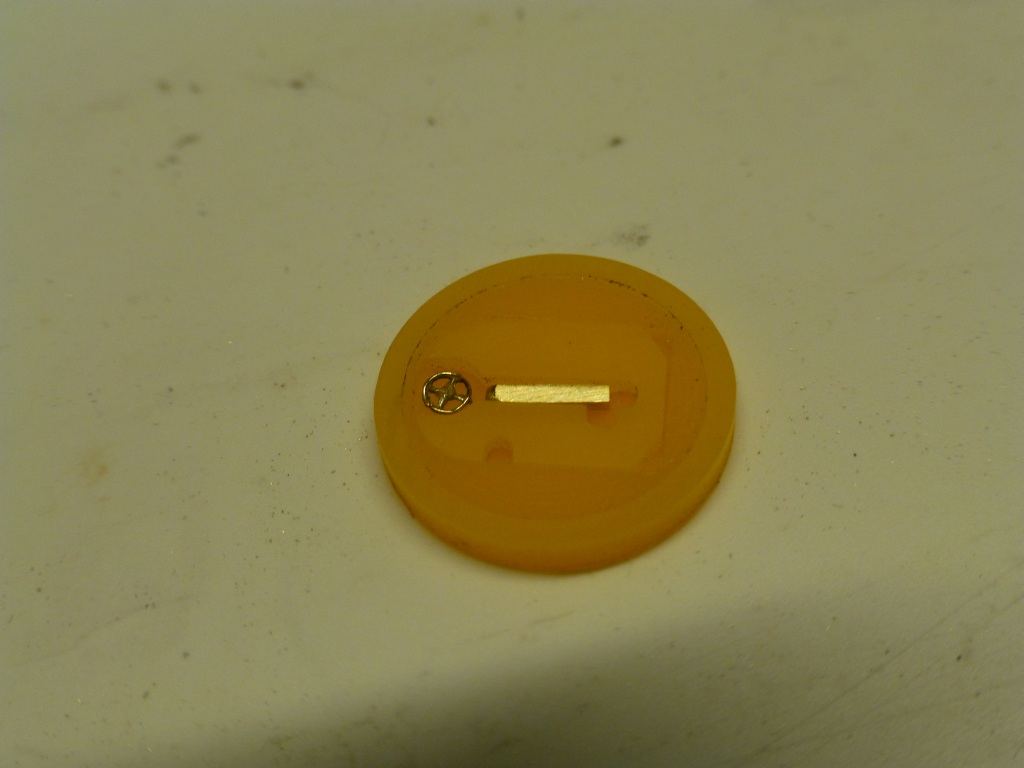

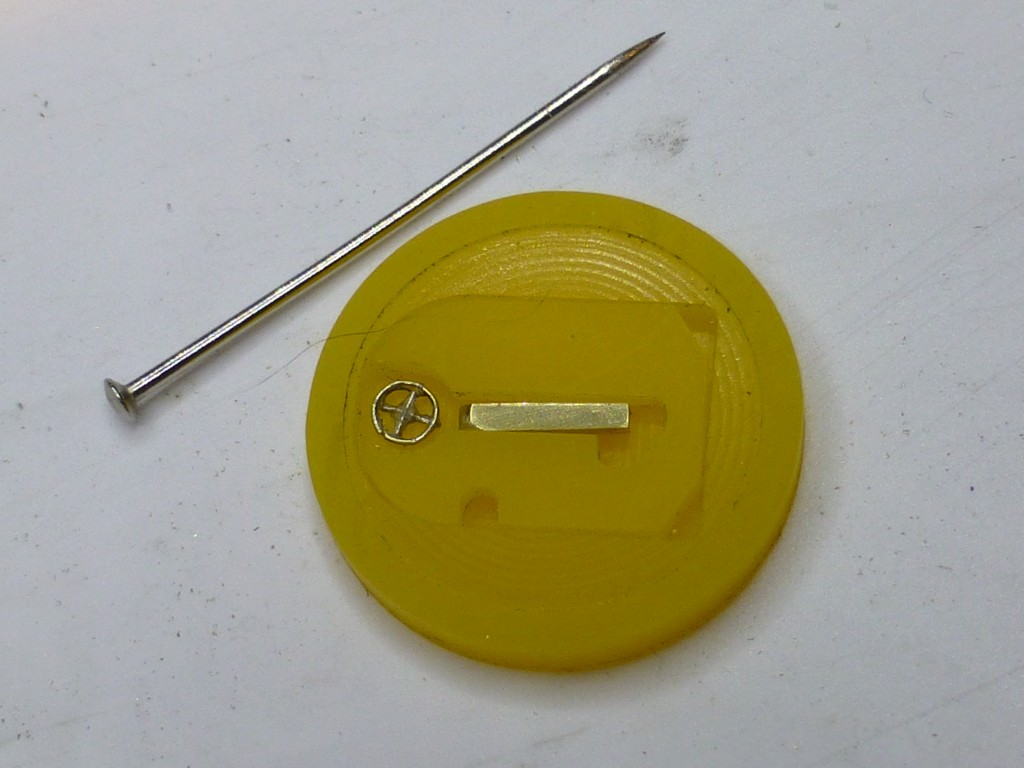

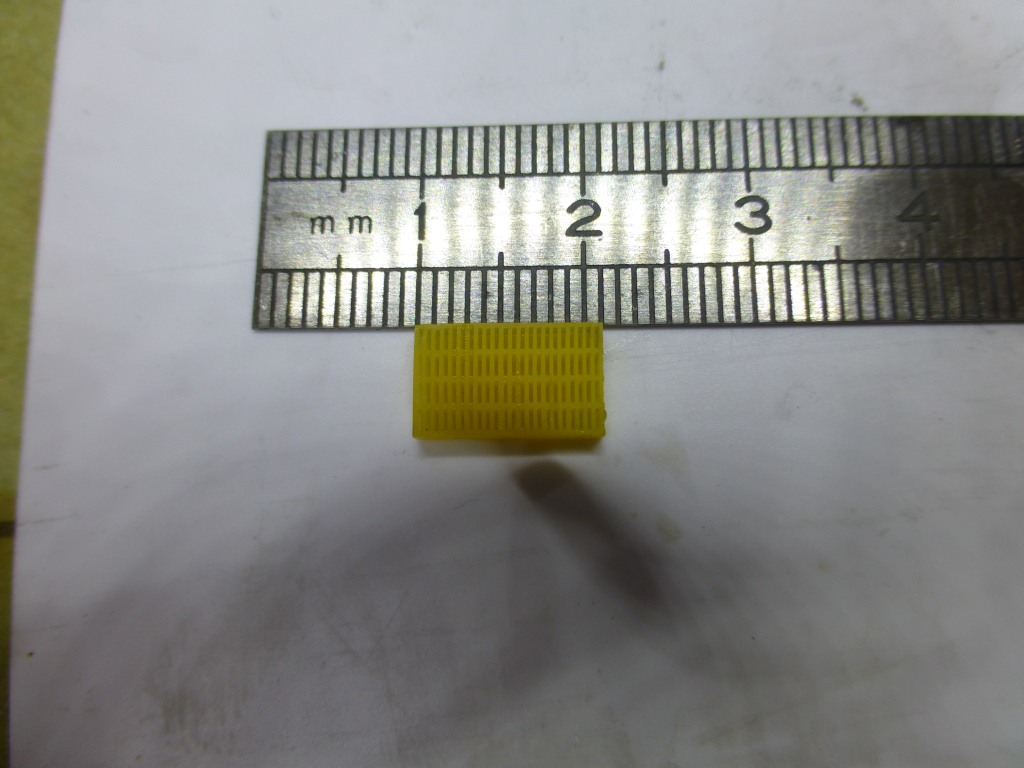

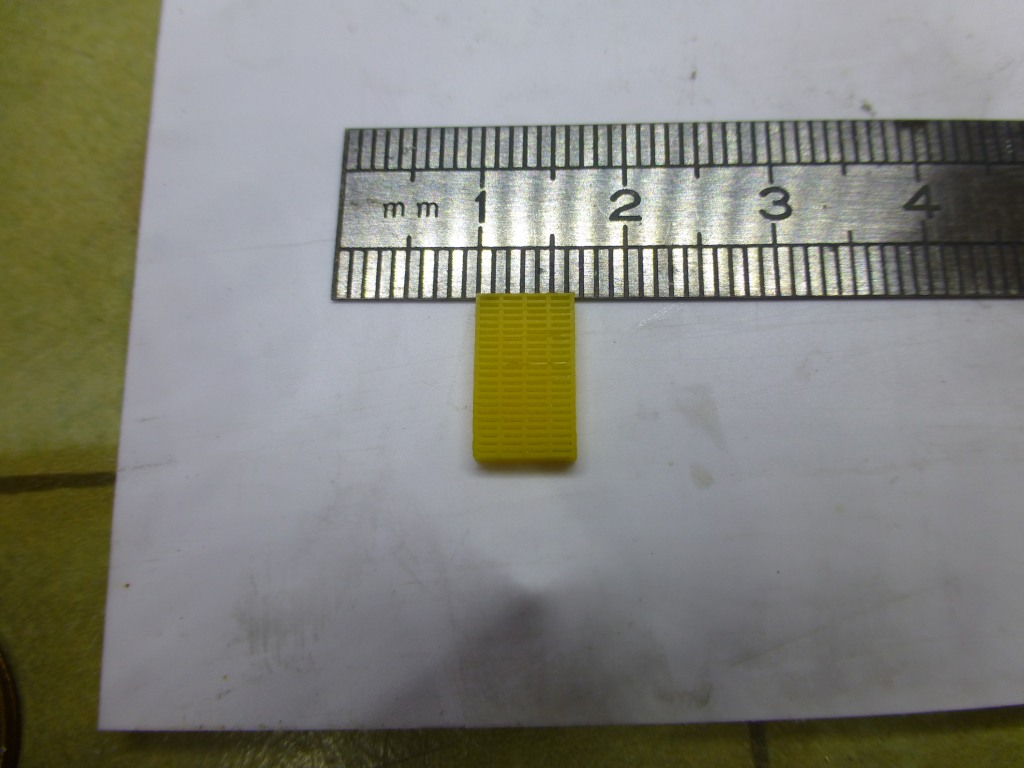

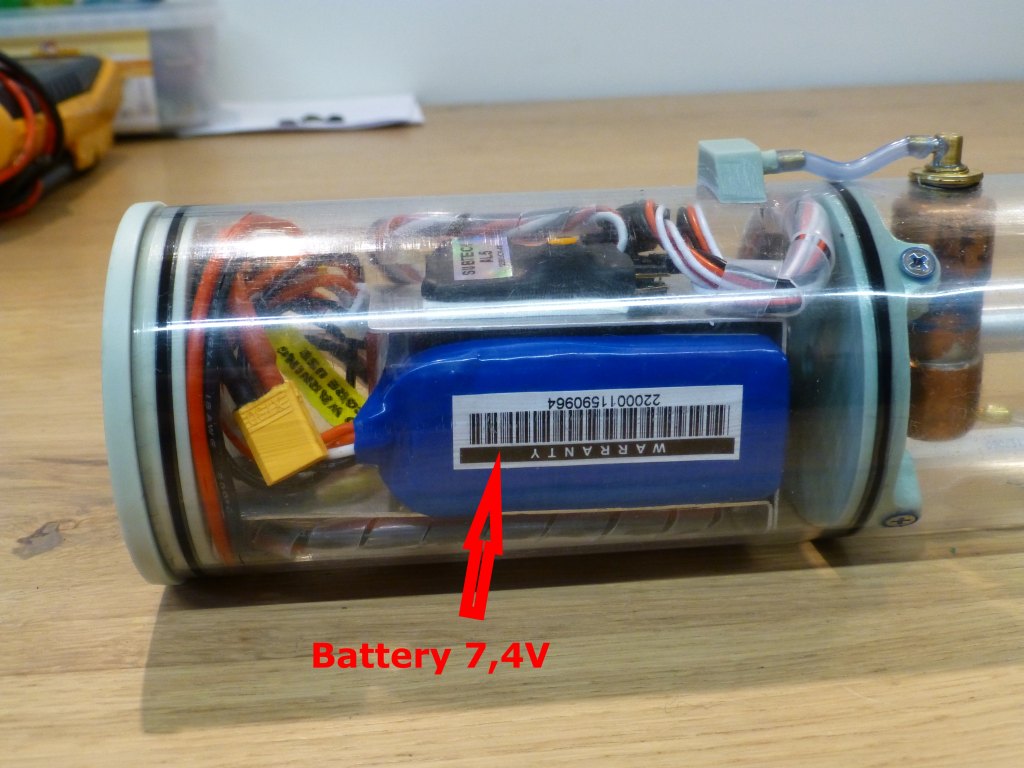

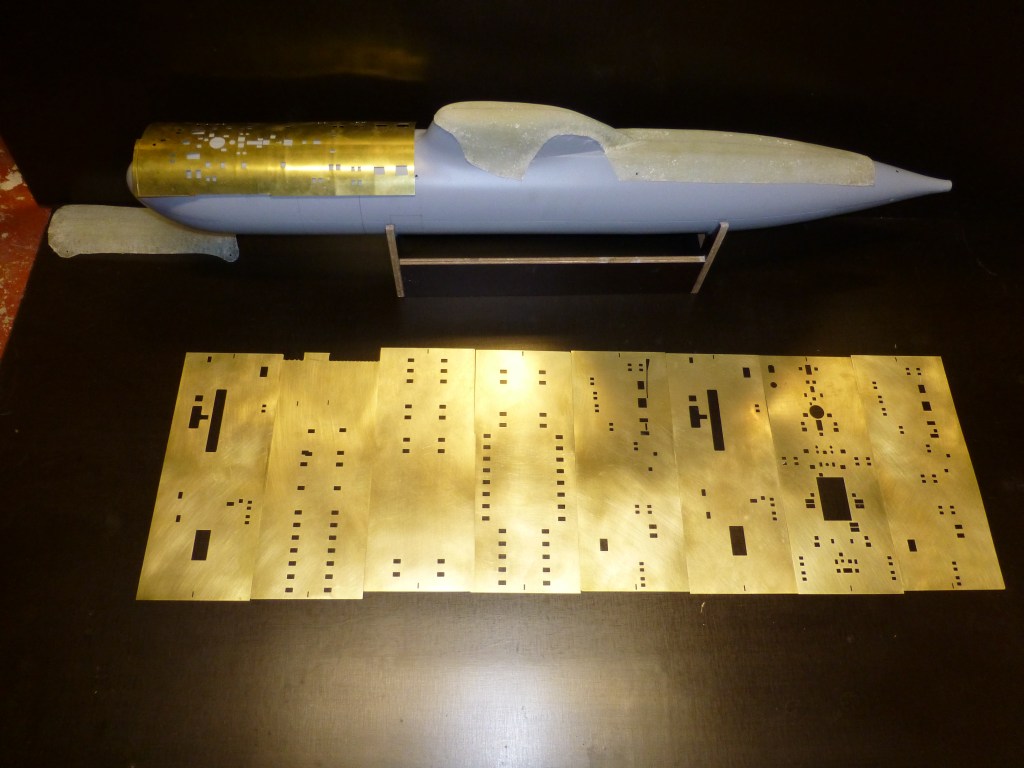

I needed 400gr of buoyancy. the piston tank that I have designed forced me to make use of the full length of available internal space. After calculating all the weight of the bits and pieces the buoyancy was slightly negative no problem if you can add some foam. But that space was not available in my case. Also the piston tank was designed as a separate tank within WTC what resulted in a decent own weight. All together my bad….No problem I love challenges like this. And it’s done before just have to steel the one that’s suit me best.

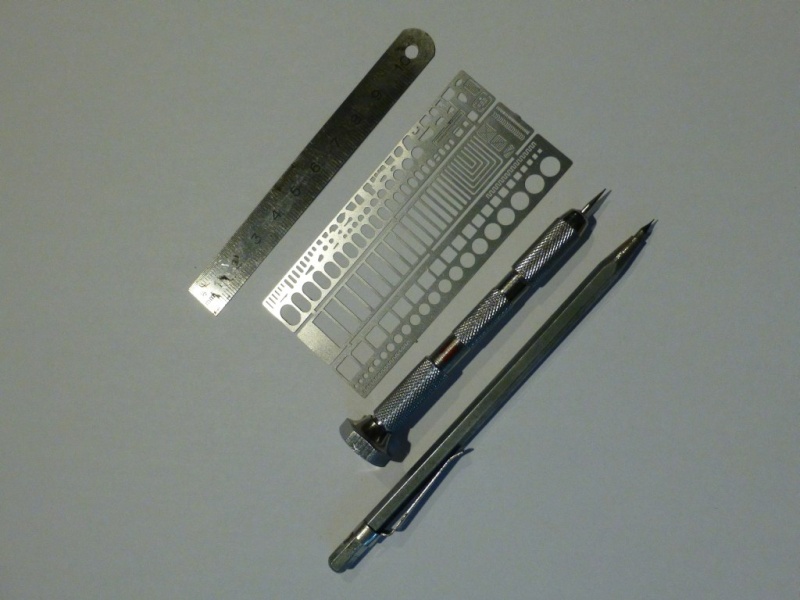

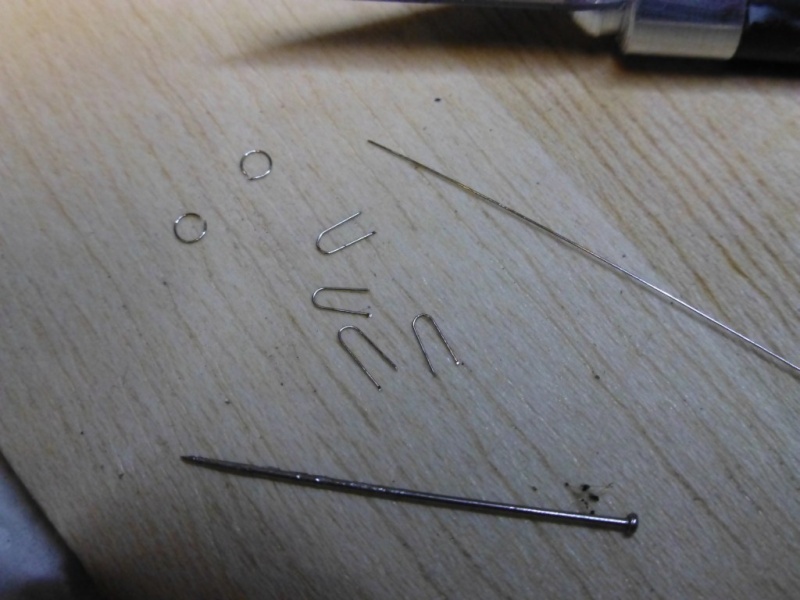

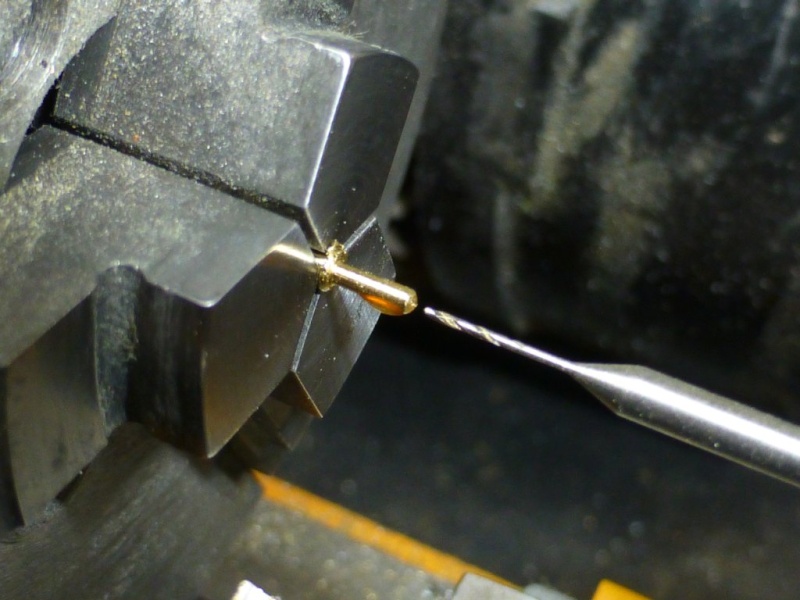

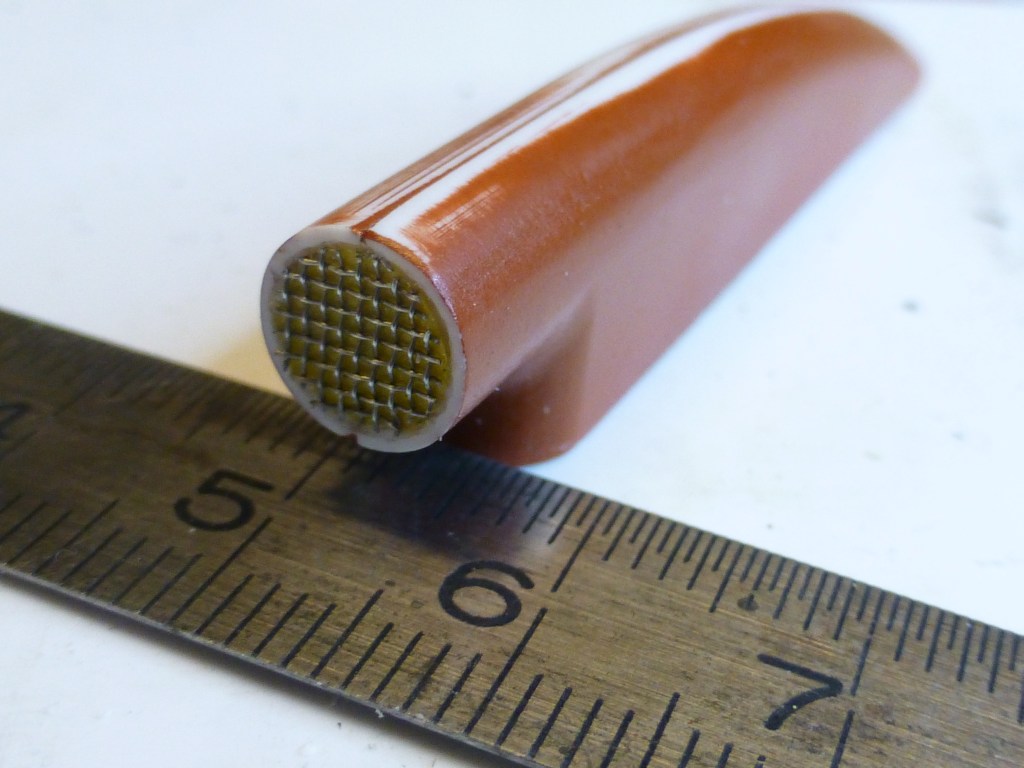

No special grade. I reduced the pointangle of my drills to 90° +-something instead of 120°, and you have to have solid support to prevent chipping. That’s the reason I had the hickcup, the piece was not supported. I also use the slowest RPM available on my drill press. To cut the darn stuff I use a fine-toothed scroll saw blade.

Can you glue polycarbonate with acetone?

Grtz,

Bart

» David Forrest's R class

» Futaba -868/915mhz equipment

» Darnell type 21 submarine, need some help

» Robbe Seawolf V2

» bladder bags

» WW2 mini sub build

» Peral Submarine of 1888

» U-Boat R/C?