Who is online?

In total there are 25 users online :: 1 Registered, 0 Hidden and 24 Guests

Most users ever online was 180 on Tue Nov 05, 2019 6:03 am

Latest topics

Search

Most Viewed Topics

Statistics

Our users have posted a total of 12477 messages in 1986 subjects

We have 1017 registered users

The newest registered user is Bazdiving

Similar topics

+4

Tom(ADMIN)

tattooed

david f

nigele(ADMIN)2

8 posters

CSS PIONEER

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°101

Re: CSS PIONEER

Re: CSS PIONEER

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°102

Re: CSS PIONEER

Re: CSS PIONEER

When gel coat has fully cured cut a piece of tissue using the same patten used to make the mould and lay in the mould,stipple resin on top of it making sure that the edges along the taped face stand up in the air,allow the tissue to fully dry before going any further,repeat this on the second half hull.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°103

Re: CSS PIONEER

Re: CSS PIONEER

This is how it should look with the tissue applied,the small centre mould is a rubbing strip for the boat just in case research shows that the original boat was fitted with them.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°104

Re: CSS PIONEER

Re: CSS PIONEER

When the tissue is fully dry add two layers of 300gsm matt cut from the patten,these are added wet on wet,this means that the matt is resin coated before being applied to the mould,again insure that the matt stand up at the edges as shown.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°105

Re: CSS PIONEER

Re: CSS PIONEER

Another view of both half hulls in the mould.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°106

Re: CSS PIONEER

Re: CSS PIONEER

When the matt has fully cured, take a sharp stanley knife and run it down the mould face along the joint edges, don't try to cut it in one go, keep running the knife down the edge gently until the excess is removed. Ensure that the knife runs along the tape so as not to damage mould face.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°107

Re: CSS PIONEER

Re: CSS PIONEER

Another view with excess removed.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°108

Re: CSS PIONEER

Re: CSS PIONEER

Now remove both half hulls from the moulds.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°109

Re: CSS PIONEER

Re: CSS PIONEER

Clean up hull edges with a rough file,insure that the long edges that join together have the burr removed but no more,when this is done wash the moulds and the half hulls and fully dry.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°110

Re: CSS PIONEER

Re: CSS PIONEER

Tape round the front and rear edges of the mould with masking tape as shown,cut two lengths of 1 inch alloy foil tape the full length of the hull plus an inch.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°111

Re: CSS PIONEER

Re: CSS PIONEER

Tape the two half hulls together at the front and rear insuring they line up correctly,as shown.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°112

Re: CSS PIONEER

Re: CSS PIONEER

Now join along the whole length of the hull using the alloy tape,removing the masking tape at the front and rear of the hull as you go,ensure that the alloy tape is pushed down on to the hull firmly and flat.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°113

Re: CSS PIONEER

Re: CSS PIONEER

Place hull back in the mould insuring that it is the correct way up.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°114

Re: CSS PIONEER

Re: CSS PIONEER

Place the other half of the mould in place and bolt them together.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°115

Re: CSS PIONEER

Re: CSS PIONEER

Looking down the inside of the hull showing the lines to be joined.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°116

Re: CSS PIONEER

Re: CSS PIONEER

Cut four strips of 300 matt 1 inch wide and 2 inches longer than the mould,it pays to taper the end that goes in the small end of the hull as shown.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°117

Re: CSS PIONEER

Re: CSS PIONEER

Extended brush I use for joining the hull halves.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°118

Re: CSS PIONEER

Re: CSS PIONEER

Wet the joint in the hull with resin and the apply the joining strips dry, one at a time stipple them into place start at the large end with the strip in a u shape and slowly unroll it down the inside the hull making sure that it remains on the centre line of the joint,this is very fiddley.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°119

Re: CSS PIONEER

Re: CSS PIONEER

When fully cured remove from mould and remove tape and trim up and thats it, one half of the hull done,do the same again for the second half of the hull,handy that its the same both end's.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°120

Re: CSS PIONEER

Re: CSS PIONEER

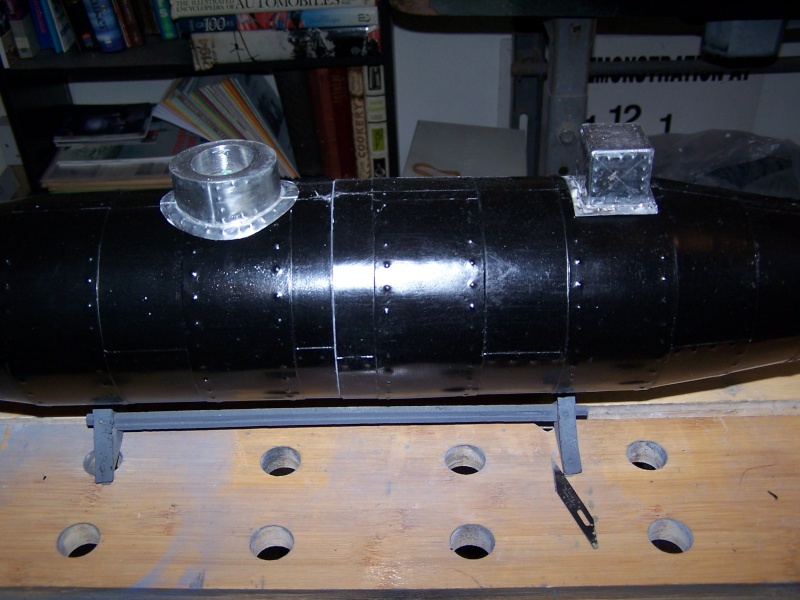

A few views of the hull with the second half done.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°121

Re: CSS PIONEER

Re: CSS PIONEER

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°122

Re: CSS PIONEER

Re: CSS PIONEER

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°123

Re: CSS PIONEER

Re: CSS PIONEER

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°124

Re: CSS PIONEER

Re: CSS PIONEER

PS...YES DAVID, THIS IS YOUR ONE!!

Last edited by nigele on Sat Feb 18, 2012 7:13 pm; edited 1 time in total

Tom(ADMIN)- AMS Forum Owner

- Posts : 3026

Join date : 2010-11-05

Age : 64

Location : Nevada, USA

- Post n°125

Re: CSS PIONEER

Re: CSS PIONEER

Awesome work, boss...a master at his craft.

» David Forrest's R class

» Futaba -868/915mhz equipment

» Darnell type 21 submarine, need some help

» Robbe Seawolf V2

» bladder bags

» WW2 mini sub build

» Peral Submarine of 1888

» U-Boat R/C?