Who is online?

In total there are 6 users online :: 0 Registered, 0 Hidden and 6 Guests

None

Most users ever online was 180 on Tue Nov 05, 2019 6:03 am

Latest topics

Search

Most Viewed Topics

Statistics

Our users have posted a total of 12449 messages in 1981 subjects

We have 1010 registered users

The newest registered user is Chris Shelley

Similar topics

+13

tieratus

tattooed

treeboa

profesorul

johnrobinson

ajg141

Hermann

NicK

nigele(ADMIN)2

Tom(ADMIN)

david f

Giovanni LiCalsi

salmon

17 posters

Piston Ballast Systems

Tom(ADMIN)- AMS Forum Owner

- Posts : 3026

Join date : 2010-11-05

Age : 64

Location : Nevada, USA

- Post n°106

Re: Piston Ballast Systems

Re: Piston Ballast Systems

This may sound silly David, but have you tried common or garden margarine? We used to use margarine to lubricate prop shafts years ago...might be worth a try?

johnrobinson- Guest

- Posts : 98

Join date : 2011-06-10

- Post n°107

PISTON TANK

PISTON TANK

HI David

What might be the best thing to do is spray the inside of the syringe with PTFE as that won't attack the plunger, what you could all so use is PTFE grease what they use for model helicopters might be worth a try. When i used to use piston ballast tanks many years ago i used to spray mine with PTFE but this stuff that i had went hard after i sprayed it on after a few minutes never had a problem with tank locking up after, had a look to see if i had still got the can of spray PTFE so i could give you the name of the company where it came from but sad to say i no longer have it but it was about 20 years ago. I have just thought of some thing else you could try PTFE that they use for mould release when doing fibre glass moulds it comes in a liquid but could be sprayed on inside of tube

Hope it helps John

What might be the best thing to do is spray the inside of the syringe with PTFE as that won't attack the plunger, what you could all so use is PTFE grease what they use for model helicopters might be worth a try. When i used to use piston ballast tanks many years ago i used to spray mine with PTFE but this stuff that i had went hard after i sprayed it on after a few minutes never had a problem with tank locking up after, had a look to see if i had still got the can of spray PTFE so i could give you the name of the company where it came from but sad to say i no longer have it but it was about 20 years ago. I have just thought of some thing else you could try PTFE that they use for mould release when doing fibre glass moulds it comes in a liquid but could be sprayed on inside of tube

Hope it helps John

Giovanni LiCalsi- Guest

- Posts : 170

Join date : 2010-11-15

Age : 73

Location : Alameda, California, USA

- Post n°108

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Take a gander at this.

http://www.parker.com/portal/site/PARKER/menuitem.de7b26ee6a659c147cf26710237ad1ca/?vgnextoid=fcc9b5bbec622110VgnVCM10000032a71dacRCRD&vgnextdiv=&vgnextcatid=4640227&vgnextcat=O-RING+LUBRICANTS&Wtky=O-RINGS&vgnextfmt=EN

http://www.parker.com/portal/site/PARKER/menuitem.de7b26ee6a659c147cf26710237ad1ca/?vgnextoid=fcc9b5bbec622110VgnVCM10000032a71dacRCRD&vgnextdiv=&vgnextcatid=4640227&vgnextcat=O-RING+LUBRICANTS&Wtky=O-RINGS&vgnextfmt=EN

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°109

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Hi All,

I've copied this private communication with Hein (who I met in Dortmund) with his permission.

Google translate has worked well for us both and it is worth looking at the detail but in a "nutshell" Hein suggests:

-Aluminium can corrode. This depends on the type of aluminium and can be prevented by anodising (which can be done at home, perhaps?)

-Aerosol cans make very good piston tanks.

-The sticking piston problem can be reduced by roughening the cylinder bore to retain lubricant.

Now read on!

Hallo David

Sie haben die neuen, transparenten Kolbentanks in ARCHI 1 + 2 in Dortmund gesehen. Außerdem sahen Sie den Kolbentank in Ex-U1, den ich aus einer Sprühsahnedose gebaut habe. Diese Dose hatte zufällig das richte Mass.

Please remember.

You have seen the new, clear piston tanks in ARCHI 1 + 2 in Dortmund.

Moreover, you saw the piston tank in Ex-U1 which I have built from a “whipped cream aerosol can”. This tin had by chance the right measure.

Die eigentliche Ursache für all diesen Aufwand war, dass die 3 Kolbentanks in den beiden ARCHIs zunächst aus ungeschütztem Aluminium Rohr bestanden. Alle 3 zeigten in kurzer Zeit Gasbildung in Folge von Elektrolyse. Nach dem Zerlegen der Kolbentanks zeigte sich im Inneren Lochfraß. Ich hatte zunächst geglaubt, dass mein bevorzugtes Silikonfett das Aluminium schützen würde. Es hat aber das Aluminium nicht geschützt. Dieser Lochfraß in der Innenwand war gerade so groß wie ein Stich mit einer dicken Nadel. Meine Versuche, diese Stelle mit Fett dicht zu machen, waren ohne Erfolg.

Weil andere Materialien, wie Rohre aus Edelstahl oder Glasfiber nicht in Frage kamen, wurden zunächst bei den ARCHIS die Kolbentanks aus Plexiglas (ARCHI 1) und Sodaflaschen (ARCHI 2) gefertigt.

Das hat Vorteile: 1. Transparent. 2. Nicht korrosiv

The real cause for all this expenditure was that 3 piston tanks passed pipe in both ARCHIs first of unprotected aluminium. Everybody 3 showed in short time gasification as a result of from electrolysis. On disassembling the piston tanks pitting corrosion appeared inside. I had first thought that my preferential silicone grease protected the aluminium. However, it has not protected the aluminium. This pitting corrosion in the inner wall was just as big as a sting with a thick needle. My attempts to shut up this place with grease were without success.

Because other materials, as pipes from high-grade steel or glass fibre were not possible, were made first with the ARCHIS the piston tanks out of Perspex (ARCHI 1) and soda bottles (ARCHI 2).

This has advantages: 1. Transparency. 2. Not corrosively

Bei Ex-U1 war die Transparenz nicht nötig, dafür aber die Beständigkeit gegen Korrosion.

Bei der Suche nach geeignetem Material fand ich dann diese Alukannen.

Eine Miniaturversion befindet sich in ARCHI 1. Hierin war ein Deo Aerosol. Hiermit werden zur Zeit 5 mml Wasser von vorne nach hinten hin und her geschoben. Das dient zum Einen dazu, einen völlig regungslos im Wasser stehenden ARCHI 1 um die Querachse zu bewegen. Das Alles geschieht im Rhythmus der Eigenschwingung von ARCHI 1.

Zum Anderen kann durch kurze Einschaltimpulse der Kolbentank zum Trimmen des ARCHI 1 genutzt werden.

In Ex-U1 the transparency was not necessary, for it, however, the permanence against corrosion.

I found with the search for suitable material then these aluminium pots.

A miniature version is in ARCHI 1. In this was a deodorant aerosol. Herewith 5 ccm water are pushed at the moment from the front to the back to and fro. This serves to one in addition to move an ARCHI 1 absolutely still standing (stupid) in the water around the transverse axis. Everything happens in the rhythm of the natural oscillation of ARCHI 1.

For the other the piston tank can be used by short switching with hand for trimming of the ARCHI 1.

Die Deckel und Kolben im meinen Kolbentanks mache ich aus Makrolon. Die Gewindestange ist aus Edelstahl. Die Bohrung im Kolben geht nur bis zu einer Tiefe von 80%. Damit hat die Gewindestange keinen Kontakt zum Wasser. Das Gewinde wird mit 2 K Kleber im Kolben gesichert.

I make the lids and pistons to my piston tanks from Makrolon. The thread pole is from high-grade steel. The drilling in the piston goes only up to a depth of 80%. With it the thread pole has no contact with the water. The thread is protected with 2 K glue in the piston.

Es gibt also 2 gute Gründe, fertige und bereits von innen geschützte Behälter für unseren Zweck zu verwenden.

Das geringe Gewicht,

Der bereits vorhandene Schutz

Der Schutzlack ist so stabil, dass ohne eine zusätzliche Behandlung das Fett zwischen O-Ring

Und Innenwand verdrängt wird. Wird der Kolbentank einige Tage nicht bewegt, ist das Fett verdrängt und der Motor muss mit viel Kraft die Reibung überwinden. Wird dagegen die Schutzlackierung vorsichtig geschliffen (mattiert), bleibt das Fett in den mikroskopisch kleinen Rillen, und der Motor kann auch nach vielen Monaten ohne Mühe den Kolben bewegen.

There are 2 good reasons, make already and from the inside protected containers for our purpose to use.

The low weight,

The already available protection

The protective varnish is so stable, that without additional treatment the grease between O ring and inner wall is edged out. If the piston tank is not moved some days, the grease is edged out and the engine must overcome the friction with a lot of strength. If the protective spraying is sharpened against it carefully (matted), the grease remains in the microscopic small grooves, and the engine can also move after many months without trouble the piston.

Hier noch ein kleines Experiment: Legen Sie ein wenig Aluminium und ein kleines Stück Messing für einige Tage in ein Glas mit Wasser. Ganz mutige Menschen streuen ein paar Salzkörner hinzu. In wenigen Stunden hat das Aluminium weiße Farbe angenommen, das Wasser wird trübe. Das ist die gefürchtete Elektrolyse. Das mindere Material, hier Aluminium wird zerstört. Dabei entsteht eine messbare Spannung.

Here still a small experiment: Lay a little piece aluminium and a small piece of brass for some time in a glass (transparency) with water. Quite courageous people strew some grains of salt into the water. In few hours the aluminium has accepted white colour, the water becomes murky. This is the dreaded electrolysis. The less material, here aluminium is destroyed. Besides, there originates a measurable tension (voltage).

Have a nice weekend

Hein

Your letter from July 10. 2012,

Hi Hein,

1. Thank you very much for the useful warnings about using pure aluminium in piston tanks. Vielen Dank für die nützlichen Warnungen über die Verwendung reinen Aluminiums als Kolbentank.

2. I am not sure what to do now because I have recently purchased quite a lot of aluminium tube. Ich bin nicht sicher, was jetzt zu tun ist, weil ich kürzlich ziemlich viel Aluminiumrohr gekauft habe.

3. Any suggestions?! Irgendwelche Vorschläge?!

God question! Next question! Gute Frage! Nächste Frage!

4. Sie äußern sich über Aerosol-Dosen, und angeraute Oberflächen, um das Fett zu behalten, sind auch sehr nützlich.

You comments on aerosol cans and roughening surfaces to retain grease are very useful too.

5. Könnte ich Ihre E-Mail und die sehr gute Übersetzung im AMS Forum veröffentlichen?

Could I post your email and the very good translation on the AMS Forum?

Regards,

David

Noch einmal vielen Dank für Ihre Hilfe, Thanks again for your help, David

Gut, wer A sagt, muß auch B sagen. Who says A, B must also say!

Eine andere Version lautet: Wer A sagt, muß nicht zwangsläufig B sagen. Besonders dann, wenn er erkannt hat, dass B falsch ist. Another version is: Who says A, B must not say necessarily. Particularly if he has recognised that B is wrong.

Punkt 1.

Ich bedanke mich, daß Sie mir wenigstens zugehört haben. Das ist nicht immer so…

Meine Rohre stammen von einer Autobahnmeisterei. Wenn an einer Autobahn ein Schild aufzustellen ist, dann nehmen die Monteure von einer ganzen Rohrlänge soviel ab, wie gerade benötigt wird. Die Reste gelangten dann irgendwann zu uns in die Modell – Uboot Szene. Der Modellbau Kollege, der als Mitarbeiter dieser Firma uns mit solchem Material versorgte, versicherte uns, solche Rohre seien gegen winterliches Streusalz resistent. Als ich ihm später von meinen Erfahrungen berichtet habe, meinte er leichthin, ich solle das nicht so tragisch nehmen, immerhin habe er kein Geld dafür verlangt! Und für ihren eigentlichen

Verwendungszweck seien sie allemal gut genug. Da hat der Gute nicht einmal Unrecht.

Damit will ich sagen, niemand, auch nicht unser spendabler Kollege kennt die genaue Zusammensetzung dieser Rohre.

Wir wissen, dass es auf dem Markt unterschiedliche Qualitäten gibt. Mir liegt hier ein Katalog vor, wo bei Rohren folgende Angaben gemacht werden:

Qualität: Al Mg Si 0,5, (Eloxalqualität), Festigkeit F22, gut eloxierbar, gut schweißbar

Herstellungslänge: ca.: 6m

Natürlich gibt es auch Seewasser beständiges Aluminium als Rohr. Die Frage ist nur wo, und zu welchem Preis. Und müssen wir Verbraucher nicht das glauben, was man uns erzählt?

I thank that you have at least belonged to me. This not always is in such a way.

My pipes are coming from an “agency in charge of highway maintenance”. If on a highway a sign is to be put up, the assemblers decrease from a whole pipe length so much as is just required. Then the rests reached sometime to us in the model – sub scene. The model builder colleague who supplied us with such material as an employee of this company assured us, such pipes are resistant by wintry litter salt. When I have reported to him later about my experiences, he believed casually, I should not take so tragically, at least, he has required no money for it! And for her real one

Intended purpose they are good enough always. There is not even wrong to the goodness.

With it I want to say, nobody, also not our generous colleague knows the exact composition of these pipes.

We know that there are different qualities at the market. Here a catalogue is given to me where with pipes the following information is provided:

quality: Al mg Si 0.5, (Anodizeable quality), firmness F22

well anodizeable, well weldable, Production length: approx.: 6 m

Of course there is also sea water continual aluminium as a pipe. The question is only where, and for which price. And must we not believe consumer this what one tells us?

Punkt 2 + 3.

Was Ihre Rohre angeht, vielleicht kann Ihr Händler etwas zu der gelieferten Qualität sagen?

Oder gibt es vielleicht in Barrow – bei den großen Jungs – eine Quelle, die man anzapfen kann?

Ansonsten bleibt nur, die Innenseite der Aluminiumzylinder regelmäßig zu kontrollieren. Sie erinnern sich, dass Sie bei meinen Kolbentanks den freien Blick durch die Deckel und den Kolben genießen konnten. Das sieht nicht nur schön aus, es trägt auch zu einer einfachen Sichtkontrolle bei.

Bei einem meiner Modelle leuchten auf Knopfdruck ein paar LEDs im Deckel des KT zu dessen einfacher Innenkontrolle.)

Ich denke, dass ein Versuch mit einem Reststück Aluminiumrohr in einen Behälter mit Wasser rasch Klarheit verschafft, ob das frisch gekaufte Rohr Ihren Erwartungen entspricht. Es wäre schade, wenn die Investition von Geld und Arbeit in unbrauchbarem Rohr zu frühzeitigem Verschleiß führen würde.

What concerns your pipes, maybe your trader can say something to the delivered quality?

Or is there maybe in Barrow – with the big boys – a spring which one can tap?

Otherwise remains only to control the inside of the aluminium cylinders regularly.

You remember that you could enjoy the free look by the lids and the pistons with my piston tanks. This looks not only nice it also contributes to an easy view control.

With one of my models shine at the touch of a button some LEDs in the lid of the KT to his easy inside control.)

I think that an trial with a test piece gets aluminium pipe in a container with water quickly clarity whether the freshly bought pipe corresponds to your expectations.

It would be a pity if the investment of money and work led in useless pipe to untimely wear.

Mir ist da noch eine weitere Lösung eingefallen: Eloxierte Rohre. Es gibt für die Pneumatik innen und außen eloxierte Rohre. Diese Schicht sieht unter dem Mikroskop wie eine Berg- und Tallandschaft aus. Hierin findet das Schmiermittel sicheren Halt. Der O-Ring gleitet über die „Bergkuppen“ während die „Täler“ mit Fett gefüllt sind. Eloxiertes Aluminium ist durch diese Schicht quasi mit einem „Edeloxyd“ versehen und kann deshalb nicht weiter Korrodieren. Außerdem wird Oberfläche dadurch gehärtet.

Pneumatik Firmen machen daraus ihre Zylinder. Sie schneiden die jeweils benötigte Menge von langen Rohren ab. Die einzig ungeschützten Stellen sind die Schnittflächen.

Die Beschaffung solch exotischer Dinge ist allerdings nicht einfach. Der vorhin erwähnte KT mit den LEDs besteht aus solchem Rohr. Sein Innendurchmesser beträgt 100 mm. Die Wandstärke ist 2,4 mm. Erhalten habe ich dieses Material von einem Kollegen, der am Bodensee lebt. Leider habe ich seit Jahren keinen Kontakt mehr zu ihm.

Bei meiner Suche nach geeignetem Material war ich mit normalem, ungeschützten Alurohr in einer Eloxierwerkstatt. Man wollte mir schon dieses Rohr bearbeiten, aber niemand konnte mir sagen, ob die für uns wichtige Innenseite auch genügend Schutz bekäme. Deshalb habe ich dann auf diese beschichteten Aerosol Dosen zurückgegriffen.

Es gibt im NET eine Firma, die alle benötigten Dinge für das Eloxieren verkauft.

Still an other solution has occurred there to me: Anodized pipes. There are for the pneumatics inside and outside anodized pipes. This layer looks under the microscope like a mountain landscape and valley scenery. In this the lubricant finds sure hold. The KDN-Ring glides about the "mountain tops" during the "valleys" with fat are filled. Anodized aluminium is provided by this layer virtually with a "noble oxide" and, therefore, is not able of wide corroding. Moreover, surface is thereby hardened.

Her cylinders make pneumatics companies from it. They cut off the in each case required amount from long pipes. The only unprotected places are the cut surfaces.

However, the procurement such of exotic things is not easy. The KT mentioned just now with the LEDs exists of such pipe. His inside diameter amounts to 100 mm. The wall strength is 2.4 mm. I have received this material from a colleague who lives by the Lake of Constance. Unfortunately, I have for many years no more contact to him.

With my search for suitable material I was with normal, unprotected aluminium pipe in an factory of anodising. One already wanted to work on to me this pipe, but nobody could say me whether the inside important for us also got enough protection. Then, therefore, I have fallen back on this coated aerosol tins.

There is in the NET a company which sells all required things for home made anodizing.

Punkt 4

Auch das ist das Ergebnis von einigen Versuchen. Als wenige Tage nach dem Zusammenbau des ersten KT aus einer Aerosoldose der Motor den Kolben nicht mehr bewegen konnte, fingen die Experimente wieder an.

Zum Glück stellte sich bald heraus, dass die harte Seite solche doppelten Schwämme, wie sie in jedem Haushalt benutzt werden, für diesen Zweck wie geschaffen sind. Mit der harten und trockenen Seite eines unbenutzten Schwammes wird die lackierte Innenseite vorsichtig angeraut. Eine ständige Sichtkontrolle ist notwendig. Wird zu lange geschliffen, besteht die Gefahr, den Lack partiell komplett zu entfernen. Dann gehört der KT in den Müll und man braucht erneut frische Erdbeeren mit Schlagsahne…

Also this is the result of some attempts. When few days after the assembly of the first KT from an aerosol tin the engine could not move the piston any more, the experiments resumed.

Luckily soon turned out that the hard side such double sponges, as they are used in every household, for this purpose like are created. With the hard and dry side of an unused sponge the varnished inside becomes carefully matted. A constant view control is necessary. It is sharpened too long, exists the danger to remove the varnish partially completely. Then belongs of the KT in the garbage and one needs fresh strawberries with whipped cream once more …

Punkt 5

Ich befürchte, dass ich dagegen nichts machen kann.

Also gut. Einverstanden! Bitte kürzen Sie den Text, wo Sie es für richtig halten.

I fear that I can make against it nothing.

So well, all right! Please, shorten the text where you hold it for right.

Sie sehen, unser Zusammentreffen in Dortmund hätte noch viel effizienter sein können. Unser Hobby hat so viele Facetten, die man nicht „mal eben zwischen Tür und Angel“ behandeln kann.

You see, our meeting in Dortmund could still have been more efficient much. Our hobby has so many facets which one cannot treat „just between door and hinge“.

Please look to this adresses

http://www.simrit.co.uk/web/public/products

search: O-Ring, or Airzet-Ring, or KDN-Ring. I love this parts.

http://www.electronic-thingks.de/de/startseite There is an English translation.

Now, however, I must break off, otherwise becomes still a full-length subject.

Hein

I've copied this private communication with Hein (who I met in Dortmund) with his permission.

Google translate has worked well for us both and it is worth looking at the detail but in a "nutshell" Hein suggests:

-Aluminium can corrode. This depends on the type of aluminium and can be prevented by anodising (which can be done at home, perhaps?)

-Aerosol cans make very good piston tanks.

-The sticking piston problem can be reduced by roughening the cylinder bore to retain lubricant.

Now read on!

Hallo David

Sie haben die neuen, transparenten Kolbentanks in ARCHI 1 + 2 in Dortmund gesehen. Außerdem sahen Sie den Kolbentank in Ex-U1, den ich aus einer Sprühsahnedose gebaut habe. Diese Dose hatte zufällig das richte Mass.

Please remember.

You have seen the new, clear piston tanks in ARCHI 1 + 2 in Dortmund.

Moreover, you saw the piston tank in Ex-U1 which I have built from a “whipped cream aerosol can”. This tin had by chance the right measure.

Die eigentliche Ursache für all diesen Aufwand war, dass die 3 Kolbentanks in den beiden ARCHIs zunächst aus ungeschütztem Aluminium Rohr bestanden. Alle 3 zeigten in kurzer Zeit Gasbildung in Folge von Elektrolyse. Nach dem Zerlegen der Kolbentanks zeigte sich im Inneren Lochfraß. Ich hatte zunächst geglaubt, dass mein bevorzugtes Silikonfett das Aluminium schützen würde. Es hat aber das Aluminium nicht geschützt. Dieser Lochfraß in der Innenwand war gerade so groß wie ein Stich mit einer dicken Nadel. Meine Versuche, diese Stelle mit Fett dicht zu machen, waren ohne Erfolg.

Weil andere Materialien, wie Rohre aus Edelstahl oder Glasfiber nicht in Frage kamen, wurden zunächst bei den ARCHIS die Kolbentanks aus Plexiglas (ARCHI 1) und Sodaflaschen (ARCHI 2) gefertigt.

Das hat Vorteile: 1. Transparent. 2. Nicht korrosiv

The real cause for all this expenditure was that 3 piston tanks passed pipe in both ARCHIs first of unprotected aluminium. Everybody 3 showed in short time gasification as a result of from electrolysis. On disassembling the piston tanks pitting corrosion appeared inside. I had first thought that my preferential silicone grease protected the aluminium. However, it has not protected the aluminium. This pitting corrosion in the inner wall was just as big as a sting with a thick needle. My attempts to shut up this place with grease were without success.

Because other materials, as pipes from high-grade steel or glass fibre were not possible, were made first with the ARCHIS the piston tanks out of Perspex (ARCHI 1) and soda bottles (ARCHI 2).

This has advantages: 1. Transparency. 2. Not corrosively

Bei Ex-U1 war die Transparenz nicht nötig, dafür aber die Beständigkeit gegen Korrosion.

Bei der Suche nach geeignetem Material fand ich dann diese Alukannen.

Eine Miniaturversion befindet sich in ARCHI 1. Hierin war ein Deo Aerosol. Hiermit werden zur Zeit 5 mml Wasser von vorne nach hinten hin und her geschoben. Das dient zum Einen dazu, einen völlig regungslos im Wasser stehenden ARCHI 1 um die Querachse zu bewegen. Das Alles geschieht im Rhythmus der Eigenschwingung von ARCHI 1.

Zum Anderen kann durch kurze Einschaltimpulse der Kolbentank zum Trimmen des ARCHI 1 genutzt werden.

In Ex-U1 the transparency was not necessary, for it, however, the permanence against corrosion.

I found with the search for suitable material then these aluminium pots.

A miniature version is in ARCHI 1. In this was a deodorant aerosol. Herewith 5 ccm water are pushed at the moment from the front to the back to and fro. This serves to one in addition to move an ARCHI 1 absolutely still standing (stupid) in the water around the transverse axis. Everything happens in the rhythm of the natural oscillation of ARCHI 1.

For the other the piston tank can be used by short switching with hand for trimming of the ARCHI 1.

Die Deckel und Kolben im meinen Kolbentanks mache ich aus Makrolon. Die Gewindestange ist aus Edelstahl. Die Bohrung im Kolben geht nur bis zu einer Tiefe von 80%. Damit hat die Gewindestange keinen Kontakt zum Wasser. Das Gewinde wird mit 2 K Kleber im Kolben gesichert.

I make the lids and pistons to my piston tanks from Makrolon. The thread pole is from high-grade steel. The drilling in the piston goes only up to a depth of 80%. With it the thread pole has no contact with the water. The thread is protected with 2 K glue in the piston.

Es gibt also 2 gute Gründe, fertige und bereits von innen geschützte Behälter für unseren Zweck zu verwenden.

Das geringe Gewicht,

Der bereits vorhandene Schutz

Der Schutzlack ist so stabil, dass ohne eine zusätzliche Behandlung das Fett zwischen O-Ring

Und Innenwand verdrängt wird. Wird der Kolbentank einige Tage nicht bewegt, ist das Fett verdrängt und der Motor muss mit viel Kraft die Reibung überwinden. Wird dagegen die Schutzlackierung vorsichtig geschliffen (mattiert), bleibt das Fett in den mikroskopisch kleinen Rillen, und der Motor kann auch nach vielen Monaten ohne Mühe den Kolben bewegen.

There are 2 good reasons, make already and from the inside protected containers for our purpose to use.

The low weight,

The already available protection

The protective varnish is so stable, that without additional treatment the grease between O ring and inner wall is edged out. If the piston tank is not moved some days, the grease is edged out and the engine must overcome the friction with a lot of strength. If the protective spraying is sharpened against it carefully (matted), the grease remains in the microscopic small grooves, and the engine can also move after many months without trouble the piston.

Hier noch ein kleines Experiment: Legen Sie ein wenig Aluminium und ein kleines Stück Messing für einige Tage in ein Glas mit Wasser. Ganz mutige Menschen streuen ein paar Salzkörner hinzu. In wenigen Stunden hat das Aluminium weiße Farbe angenommen, das Wasser wird trübe. Das ist die gefürchtete Elektrolyse. Das mindere Material, hier Aluminium wird zerstört. Dabei entsteht eine messbare Spannung.

Here still a small experiment: Lay a little piece aluminium and a small piece of brass for some time in a glass (transparency) with water. Quite courageous people strew some grains of salt into the water. In few hours the aluminium has accepted white colour, the water becomes murky. This is the dreaded electrolysis. The less material, here aluminium is destroyed. Besides, there originates a measurable tension (voltage).

Have a nice weekend

Hein

Your letter from July 10. 2012,

Hi Hein,

1. Thank you very much for the useful warnings about using pure aluminium in piston tanks. Vielen Dank für die nützlichen Warnungen über die Verwendung reinen Aluminiums als Kolbentank.

2. I am not sure what to do now because I have recently purchased quite a lot of aluminium tube. Ich bin nicht sicher, was jetzt zu tun ist, weil ich kürzlich ziemlich viel Aluminiumrohr gekauft habe.

3. Any suggestions?! Irgendwelche Vorschläge?!

God question! Next question! Gute Frage! Nächste Frage!

4. Sie äußern sich über Aerosol-Dosen, und angeraute Oberflächen, um das Fett zu behalten, sind auch sehr nützlich.

You comments on aerosol cans and roughening surfaces to retain grease are very useful too.

5. Könnte ich Ihre E-Mail und die sehr gute Übersetzung im AMS Forum veröffentlichen?

Could I post your email and the very good translation on the AMS Forum?

Regards,

David

Noch einmal vielen Dank für Ihre Hilfe, Thanks again for your help, David

Gut, wer A sagt, muß auch B sagen. Who says A, B must also say!

Eine andere Version lautet: Wer A sagt, muß nicht zwangsläufig B sagen. Besonders dann, wenn er erkannt hat, dass B falsch ist. Another version is: Who says A, B must not say necessarily. Particularly if he has recognised that B is wrong.

Punkt 1.

Ich bedanke mich, daß Sie mir wenigstens zugehört haben. Das ist nicht immer so…

Meine Rohre stammen von einer Autobahnmeisterei. Wenn an einer Autobahn ein Schild aufzustellen ist, dann nehmen die Monteure von einer ganzen Rohrlänge soviel ab, wie gerade benötigt wird. Die Reste gelangten dann irgendwann zu uns in die Modell – Uboot Szene. Der Modellbau Kollege, der als Mitarbeiter dieser Firma uns mit solchem Material versorgte, versicherte uns, solche Rohre seien gegen winterliches Streusalz resistent. Als ich ihm später von meinen Erfahrungen berichtet habe, meinte er leichthin, ich solle das nicht so tragisch nehmen, immerhin habe er kein Geld dafür verlangt! Und für ihren eigentlichen

Verwendungszweck seien sie allemal gut genug. Da hat der Gute nicht einmal Unrecht.

Damit will ich sagen, niemand, auch nicht unser spendabler Kollege kennt die genaue Zusammensetzung dieser Rohre.

Wir wissen, dass es auf dem Markt unterschiedliche Qualitäten gibt. Mir liegt hier ein Katalog vor, wo bei Rohren folgende Angaben gemacht werden:

Qualität: Al Mg Si 0,5, (Eloxalqualität), Festigkeit F22, gut eloxierbar, gut schweißbar

Herstellungslänge: ca.: 6m

Natürlich gibt es auch Seewasser beständiges Aluminium als Rohr. Die Frage ist nur wo, und zu welchem Preis. Und müssen wir Verbraucher nicht das glauben, was man uns erzählt?

I thank that you have at least belonged to me. This not always is in such a way.

My pipes are coming from an “agency in charge of highway maintenance”. If on a highway a sign is to be put up, the assemblers decrease from a whole pipe length so much as is just required. Then the rests reached sometime to us in the model – sub scene. The model builder colleague who supplied us with such material as an employee of this company assured us, such pipes are resistant by wintry litter salt. When I have reported to him later about my experiences, he believed casually, I should not take so tragically, at least, he has required no money for it! And for her real one

Intended purpose they are good enough always. There is not even wrong to the goodness.

With it I want to say, nobody, also not our generous colleague knows the exact composition of these pipes.

We know that there are different qualities at the market. Here a catalogue is given to me where with pipes the following information is provided:

quality: Al mg Si 0.5, (Anodizeable quality), firmness F22

well anodizeable, well weldable, Production length: approx.: 6 m

Of course there is also sea water continual aluminium as a pipe. The question is only where, and for which price. And must we not believe consumer this what one tells us?

Punkt 2 + 3.

Was Ihre Rohre angeht, vielleicht kann Ihr Händler etwas zu der gelieferten Qualität sagen?

Oder gibt es vielleicht in Barrow – bei den großen Jungs – eine Quelle, die man anzapfen kann?

Ansonsten bleibt nur, die Innenseite der Aluminiumzylinder regelmäßig zu kontrollieren. Sie erinnern sich, dass Sie bei meinen Kolbentanks den freien Blick durch die Deckel und den Kolben genießen konnten. Das sieht nicht nur schön aus, es trägt auch zu einer einfachen Sichtkontrolle bei.

Bei einem meiner Modelle leuchten auf Knopfdruck ein paar LEDs im Deckel des KT zu dessen einfacher Innenkontrolle.)

Ich denke, dass ein Versuch mit einem Reststück Aluminiumrohr in einen Behälter mit Wasser rasch Klarheit verschafft, ob das frisch gekaufte Rohr Ihren Erwartungen entspricht. Es wäre schade, wenn die Investition von Geld und Arbeit in unbrauchbarem Rohr zu frühzeitigem Verschleiß führen würde.

What concerns your pipes, maybe your trader can say something to the delivered quality?

Or is there maybe in Barrow – with the big boys – a spring which one can tap?

Otherwise remains only to control the inside of the aluminium cylinders regularly.

You remember that you could enjoy the free look by the lids and the pistons with my piston tanks. This looks not only nice it also contributes to an easy view control.

With one of my models shine at the touch of a button some LEDs in the lid of the KT to his easy inside control.)

I think that an trial with a test piece gets aluminium pipe in a container with water quickly clarity whether the freshly bought pipe corresponds to your expectations.

It would be a pity if the investment of money and work led in useless pipe to untimely wear.

Mir ist da noch eine weitere Lösung eingefallen: Eloxierte Rohre. Es gibt für die Pneumatik innen und außen eloxierte Rohre. Diese Schicht sieht unter dem Mikroskop wie eine Berg- und Tallandschaft aus. Hierin findet das Schmiermittel sicheren Halt. Der O-Ring gleitet über die „Bergkuppen“ während die „Täler“ mit Fett gefüllt sind. Eloxiertes Aluminium ist durch diese Schicht quasi mit einem „Edeloxyd“ versehen und kann deshalb nicht weiter Korrodieren. Außerdem wird Oberfläche dadurch gehärtet.

Pneumatik Firmen machen daraus ihre Zylinder. Sie schneiden die jeweils benötigte Menge von langen Rohren ab. Die einzig ungeschützten Stellen sind die Schnittflächen.

Die Beschaffung solch exotischer Dinge ist allerdings nicht einfach. Der vorhin erwähnte KT mit den LEDs besteht aus solchem Rohr. Sein Innendurchmesser beträgt 100 mm. Die Wandstärke ist 2,4 mm. Erhalten habe ich dieses Material von einem Kollegen, der am Bodensee lebt. Leider habe ich seit Jahren keinen Kontakt mehr zu ihm.

Bei meiner Suche nach geeignetem Material war ich mit normalem, ungeschützten Alurohr in einer Eloxierwerkstatt. Man wollte mir schon dieses Rohr bearbeiten, aber niemand konnte mir sagen, ob die für uns wichtige Innenseite auch genügend Schutz bekäme. Deshalb habe ich dann auf diese beschichteten Aerosol Dosen zurückgegriffen.

Es gibt im NET eine Firma, die alle benötigten Dinge für das Eloxieren verkauft.

Still an other solution has occurred there to me: Anodized pipes. There are for the pneumatics inside and outside anodized pipes. This layer looks under the microscope like a mountain landscape and valley scenery. In this the lubricant finds sure hold. The KDN-Ring glides about the "mountain tops" during the "valleys" with fat are filled. Anodized aluminium is provided by this layer virtually with a "noble oxide" and, therefore, is not able of wide corroding. Moreover, surface is thereby hardened.

Her cylinders make pneumatics companies from it. They cut off the in each case required amount from long pipes. The only unprotected places are the cut surfaces.

However, the procurement such of exotic things is not easy. The KT mentioned just now with the LEDs exists of such pipe. His inside diameter amounts to 100 mm. The wall strength is 2.4 mm. I have received this material from a colleague who lives by the Lake of Constance. Unfortunately, I have for many years no more contact to him.

With my search for suitable material I was with normal, unprotected aluminium pipe in an factory of anodising. One already wanted to work on to me this pipe, but nobody could say me whether the inside important for us also got enough protection. Then, therefore, I have fallen back on this coated aerosol tins.

There is in the NET a company which sells all required things for home made anodizing.

Punkt 4

Auch das ist das Ergebnis von einigen Versuchen. Als wenige Tage nach dem Zusammenbau des ersten KT aus einer Aerosoldose der Motor den Kolben nicht mehr bewegen konnte, fingen die Experimente wieder an.

Zum Glück stellte sich bald heraus, dass die harte Seite solche doppelten Schwämme, wie sie in jedem Haushalt benutzt werden, für diesen Zweck wie geschaffen sind. Mit der harten und trockenen Seite eines unbenutzten Schwammes wird die lackierte Innenseite vorsichtig angeraut. Eine ständige Sichtkontrolle ist notwendig. Wird zu lange geschliffen, besteht die Gefahr, den Lack partiell komplett zu entfernen. Dann gehört der KT in den Müll und man braucht erneut frische Erdbeeren mit Schlagsahne…

Also this is the result of some attempts. When few days after the assembly of the first KT from an aerosol tin the engine could not move the piston any more, the experiments resumed.

Luckily soon turned out that the hard side such double sponges, as they are used in every household, for this purpose like are created. With the hard and dry side of an unused sponge the varnished inside becomes carefully matted. A constant view control is necessary. It is sharpened too long, exists the danger to remove the varnish partially completely. Then belongs of the KT in the garbage and one needs fresh strawberries with whipped cream once more …

Punkt 5

Ich befürchte, dass ich dagegen nichts machen kann.

Also gut. Einverstanden! Bitte kürzen Sie den Text, wo Sie es für richtig halten.

I fear that I can make against it nothing.

So well, all right! Please, shorten the text where you hold it for right.

Sie sehen, unser Zusammentreffen in Dortmund hätte noch viel effizienter sein können. Unser Hobby hat so viele Facetten, die man nicht „mal eben zwischen Tür und Angel“ behandeln kann.

You see, our meeting in Dortmund could still have been more efficient much. Our hobby has so many facets which one cannot treat „just between door and hinge“.

Please look to this adresses

http://www.simrit.co.uk/web/public/products

search: O-Ring, or Airzet-Ring, or KDN-Ring. I love this parts.

http://www.electronic-thingks.de/de/startseite There is an English translation.

Now, however, I must break off, otherwise becomes still a full-length subject.

Hein

tieratus- Guest

- Posts : 14

Join date : 2013-04-13

Location : Mesa,Arizona ,USA

- Post n°110

WOW !!!!!!!!! GREAT BALLAS SYSTEMS !!!!!

WOW !!!!!!!!! GREAT BALLAS SYSTEMS !!!!!

Gentlemen; As I am new to this sight I am veiwing postings and just came across

Giovanni posting of Sept.,07-2011. subject, ballas piston tanks.

All I can say is WOW!!! Great help,thank you.Now all I need is 1,000 other part

to make a sub,or is it 2,000? And HMS x1 cruiser plans .

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°111

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Glad you have found the discussion useful.

Just on a point of information about corrosion of aluminium piston tanks - I have just been looking inside one of my home made ally tanks - no signs of any corrosion after about a year of use - still bright aluminium.

David

Just on a point of information about corrosion of aluminium piston tanks - I have just been looking inside one of my home made ally tanks - no signs of any corrosion after about a year of use - still bright aluminium.

David

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°112

Re: Piston Ballast Systems

Re: Piston Ballast Systems

An update on the Piston Tank after a busy season in R7.

You can see that there is no wear or corrosion on the aluminium tube. The single Nitrile O ring has lost a bit of black colour but is in pretty good nick (I will replace it anyway) The only maintenance has been to fill and empty the tank with tap water (soft Lake District water!) after a session:

https://i.servimg.com/u/f70/18/20/23/31/img_3414.jpg

https://i.servimg.com/u/f70/18/20/23/31/img_3413.jpg

https://i.servimg.com/u/f70/18/20/23/31/img_3410.jpg

https://i.servimg.com/u/f70/18/20/23/31/img_3412.jpg

https://i.servimg.com/u/f70/18/20/23/31/img_3415.jpg

David

PS Richard, Could this be a breakthrough with my posting photos!? It seems to be working differently. Does it look OK at your end?

You can see that there is no wear or corrosion on the aluminium tube. The single Nitrile O ring has lost a bit of black colour but is in pretty good nick (I will replace it anyway) The only maintenance has been to fill and empty the tank with tap water (soft Lake District water!) after a session:

https://i.servimg.com/u/f70/18/20/23/31/img_3414.jpg

https://i.servimg.com/u/f70/18/20/23/31/img_3413.jpg

https://i.servimg.com/u/f70/18/20/23/31/img_3410.jpg

https://i.servimg.com/u/f70/18/20/23/31/img_3412.jpg

https://i.servimg.com/u/f70/18/20/23/31/img_3415.jpg

David

PS Richard, Could this be a breakthrough with my posting photos!? It seems to be working differently. Does it look OK at your end?

Tom(ADMIN)- AMS Forum Owner

- Posts : 3026

Join date : 2010-11-05

Age : 64

Location : Nevada, USA

- Post n°113

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Well...no.

All I can see is the url's to the photos, David...but it's a start!

All I can see is the url's to the photos, David...but it's a start!

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°114

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Oh No!! I will try again.

https://i.servimg.com/u/f70/18/20/23/31/img_3416.jpg

That is looking better.

David

https://i.servimg.com/u/f70/18/20/23/31/img_3416.jpg

That is looking better.

David

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°115

Re: Piston Ballast Systems

Re: Piston Ballast Systems

How's that?

Tom(ADMIN)- AMS Forum Owner

- Posts : 3026

Join date : 2010-11-05

Age : 64

Location : Nevada, USA

- Post n°116

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Excellent, David...see, I knew you could do it!

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°117

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Well Richard I would love to say that I have done something different but I have just done what I have always done. Something must have changed in the software at my end or your end.

David

David

Tom(ADMIN)- AMS Forum Owner

- Posts : 3026

Join date : 2010-11-05

Age : 64

Location : Nevada, USA

- Post n°118

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Well, whatever it is you've done, keep on doing it...I've got RSI after posting all those Barrow photos!

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°119

Re: Piston Ballast Systems

Re: Piston Ballast Systems

A good thread on this topic over on Model Boat Mayhem. Mermod builds a piston tank:

http://www.modelboatmayhem.co.uk/forum/index.php/topic,47577.0.html?PHPSESSID=dd97379acc9848fd7739039bb5971e6e

David

http://www.modelboatmayhem.co.uk/forum/index.php/topic,47577.0.html?PHPSESSID=dd97379acc9848fd7739039bb5971e6e

David

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°120

Re: Piston Ballast Systems

Re: Piston Ballast Systems

A "start of winter project update" on here:

https://www.theassociationofmodelsubmariners.com/t375-pic-microprocessors#8696

https://www.theassociationofmodelsubmariners.com/t375-pic-microprocessors#8696

John.redearth- Guest

- Posts : 16

Join date : 2012-11-30

Age : 70

Location : Melbourne Australia

- Post n°121

piston uses

piston uses

Hi

FYI my last two boats had scratch built pistons which fitted inside the central ballast tank that was operated by a pump in pump out system. A smaller piston does not give the pressure or imbalance problems the larger ones do but has all the advantages. As soon as the surface is breached, turn on the pump and empty the ballast. I haven't seen many boats with this config (none actually) but it is a very good option. The piston give fantasic fine control to get neutral buoyancy, and is triggered by the failsafe if the signal dies.

I can't actually think of a downside.

Cheers

John

FYI my last two boats had scratch built pistons which fitted inside the central ballast tank that was operated by a pump in pump out system. A smaller piston does not give the pressure or imbalance problems the larger ones do but has all the advantages. As soon as the surface is breached, turn on the pump and empty the ballast. I haven't seen many boats with this config (none actually) but it is a very good option. The piston give fantasic fine control to get neutral buoyancy, and is triggered by the failsafe if the signal dies.

I can't actually think of a downside.

Cheers

John

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°122

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Hi John,

Funnily enough this tank combination came up in a conversation I had with Nigel E recently and we both thought it sounded really good but we couldn't think of anyone using it! So it is good to hear from you!

It does seem to combine the best of both worlds with just a bit of extra complexity. Probably very good for WW2 boats where you need a low down waterline? No high pressure or overpressure problems etc.

My Resurgam model suffers a little from a too small piston tank (only about 80ml) and your idea could sort that out.

So basically you just inset the piston tank into a tank. Then use a low pressure pump for surface pump out?

Any chance of a photo?

David

Funnily enough this tank combination came up in a conversation I had with Nigel E recently and we both thought it sounded really good but we couldn't think of anyone using it! So it is good to hear from you!

It does seem to combine the best of both worlds with just a bit of extra complexity. Probably very good for WW2 boats where you need a low down waterline? No high pressure or overpressure problems etc.

My Resurgam model suffers a little from a too small piston tank (only about 80ml) and your idea could sort that out.

So basically you just inset the piston tank into a tank. Then use a low pressure pump for surface pump out?

Any chance of a photo?

David

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°123

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Yes,I used this system about twenty years ago hydraulic pistons on a central tank,it worked very well but the pressure produced would cause leaks on the pump and failure of the pump seals mainly when the boat had been unused for a few weeks and the piston seals had grabbed the cylinders,after a couple of years I changed to central tank with two electric piston control tanks,and I have used the same system on larger boats ever since,U12 s191 has had that system for seventeen years now,and I have never had to do any work on it at all.

nigele

nigele

John.redearth- Guest

- Posts : 16

Join date : 2012-11-30

Age : 70

Location : Melbourne Australia

- Post n°124

piston in tank

piston in tank

The way to go about that is to have the tank intake and outlet managed using a valve that i initially saw described by subtech. Lets water in ad out with just a little pressure.

John

John

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°125

Re: Piston Ballast Systems

Re: Piston Ballast Systems

So you need some form of valve to prevent water coming in to the tank at the surface?

(I happened to mention this thread on the phone to Nigel and I think his previous post refers to a different system (a piston moved in and out by a water pump?)

David

(I happened to mention this thread on the phone to Nigel and I think his previous post refers to a different system (a piston moved in and out by a water pump?)

David

John.redearth- Guest

- Posts : 16

Join date : 2012-11-30

Age : 70

Location : Melbourne Australia

- Post n°126

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Hi

The valve is a doddle. Have a look at this..

https://youtu.be/2YsIfgtrXhM

Best John

The valve is a doddle. Have a look at this..

https://youtu.be/2YsIfgtrXhM

Best John

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°127

Re: Piston Ballast Systems

Re: Piston Ballast Systems

That is very ingenious, John!

So the ball bearing is functioning as a non return valve and a (low) pressure relief valve? By low pressure I mean a few inches of water. It makes pump selection a doddle.

I wonder if a single one could also be used as a vent (to prevent over pressure) on an air filled bag system?

I confess I have never used a low pressure water pumped system or an airbag (I've only used pressure tank water systems and piston tanks.)but they are often talked about as solutions. But the necessary detail is often glossed over.

Low pressure water tanks + smaller piston tanks do offer benefits (as discussed earlier.)

David

PS I see that Arduinos can be programmed in C. I will give an update on my learning C shortly!

So the ball bearing is functioning as a non return valve and a (low) pressure relief valve? By low pressure I mean a few inches of water. It makes pump selection a doddle.

I wonder if a single one could also be used as a vent (to prevent over pressure) on an air filled bag system?

I confess I have never used a low pressure water pumped system or an airbag (I've only used pressure tank water systems and piston tanks.)but they are often talked about as solutions. But the necessary detail is often glossed over.

Low pressure water tanks + smaller piston tanks do offer benefits (as discussed earlier.)

David

PS I see that Arduinos can be programmed in C. I will give an update on my learning C shortly!

Last edited by david f on Fri Dec 05, 2014 11:09 am; edited 1 time in total

John.redearth- Guest

- Posts : 16

Join date : 2012-11-30

Age : 70

Location : Melbourne Australia

- Post n°128

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Yes to all of that.. keep in tough with your programming. We should exchange scripts as we go. I am not that good at it but it works so far..

david f- AMS Treasurer

- Posts : 2398

Join date : 2010-11-10

Age : 73

Location : Cumbria

- Post n°129

Re: Piston Ballast Systems

Re: Piston Ballast Systems

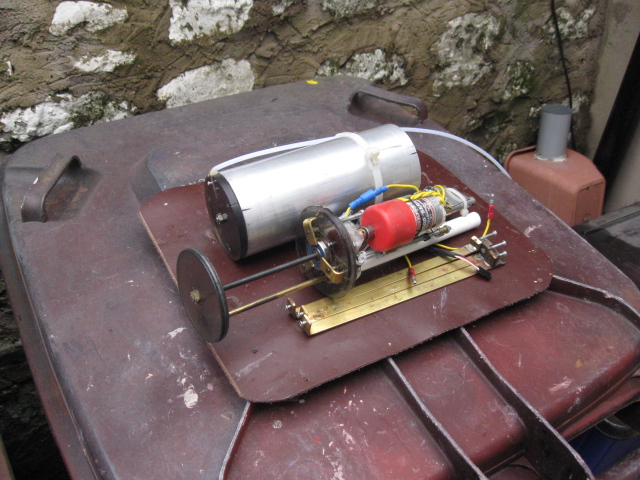

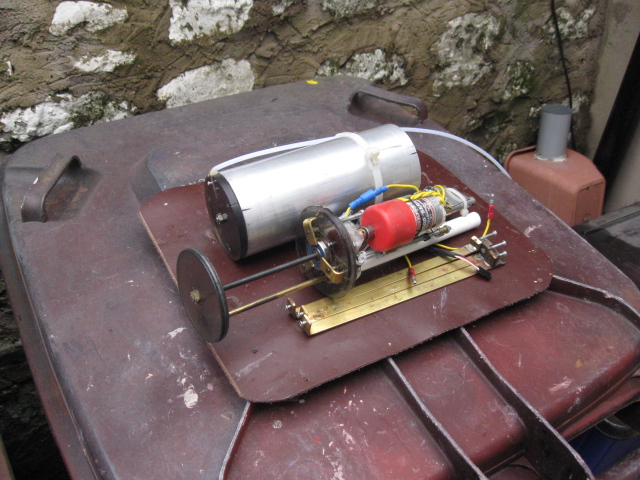

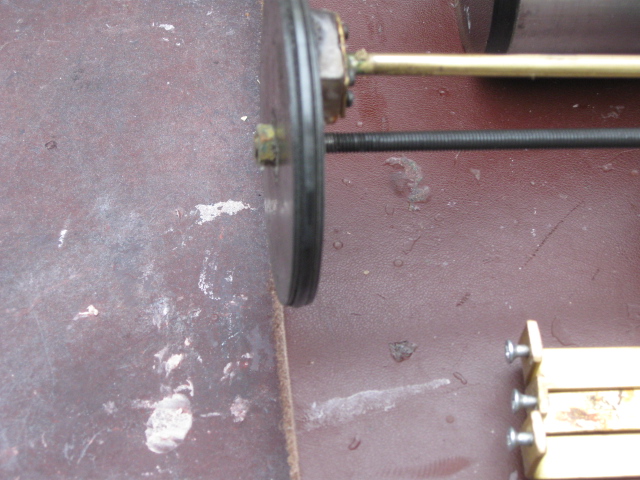

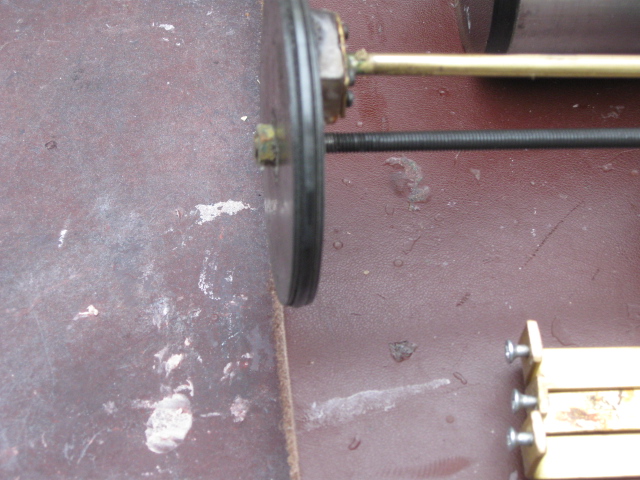

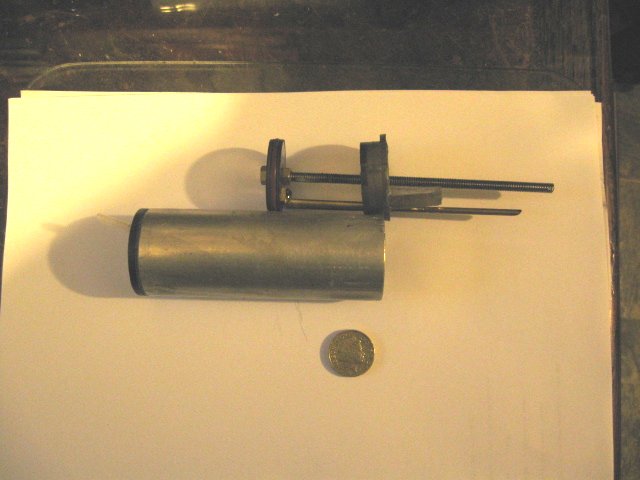

Just an update on the piston tank saga. These are home made ones I did over the course of 2015. The top one is the one used for my Holland and the lower one is used in Resurgam and the Nordenfelts. Both are now pretty much standard designs using the proportional controller but I adjust the dimensions to suit the model.

They use a standard (Nitrile) O ring. The fit is all important and does involve a bit of trial and error. Spin the piston and take small amounts out of the groove with a needle file. My rule of thumb is that you have to be able to move the piston up and down the cylinder BY HAND. (If you can't it is too tight and could stall the motor.)

The basic construction is as made by German modellers. The two photos below show the idea (This tank was originally for Resurgam but was too undersized - err on the large size! This tank uses a silicone O ring - a bit softer and with less friction. Friction seems to be a problem with smaller diameter tanks, for some reason.)

John.redearth- Guest

- Posts : 16

Join date : 2012-11-30

Age : 70

Location : Melbourne Australia

- Post n°130

Re: Piston Ballast Systems

Re: Piston Ballast Systems

An added thought. Very intersting about orings and pistons. I am in the process of building another one right now. I have found that if you cut the groove too deeply and there is not enough pressure, self sealing butyl tape can be used in the base of the groove under the o ring and keeps the seal nicely.

» Modulated electric fields for submarine communication in a "heads up" from Harry!

» 868/915 Mhz as a viable frequency for submarines.

» Laser cut Robbe U47 conversion

» ExpressLRS - 868/915 Mhz equipment

» Information on camouflage patterns for German seahund

» WW2 mini sub build

» Not the hobby I expected :)

» Sheerline gasket material