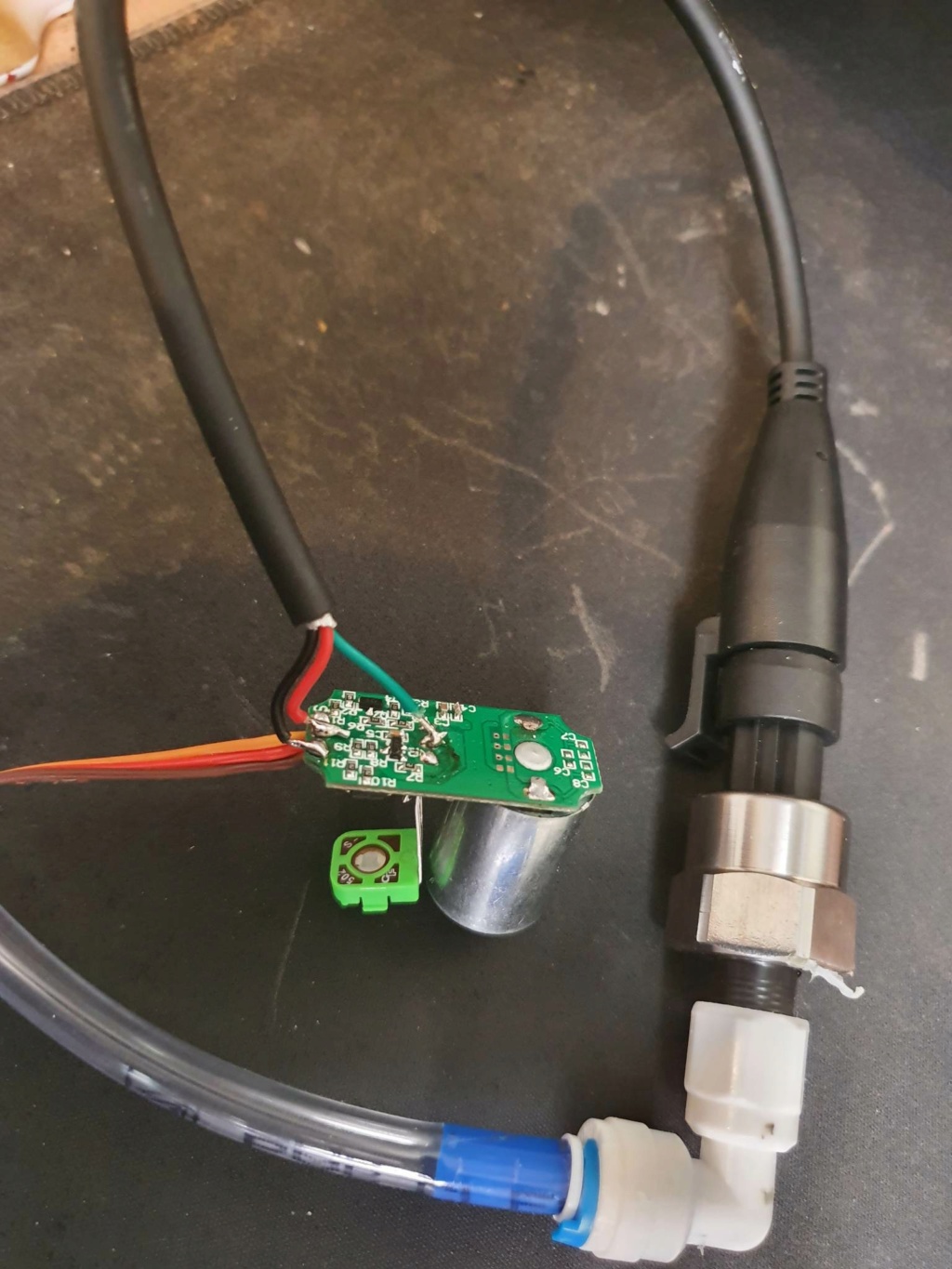

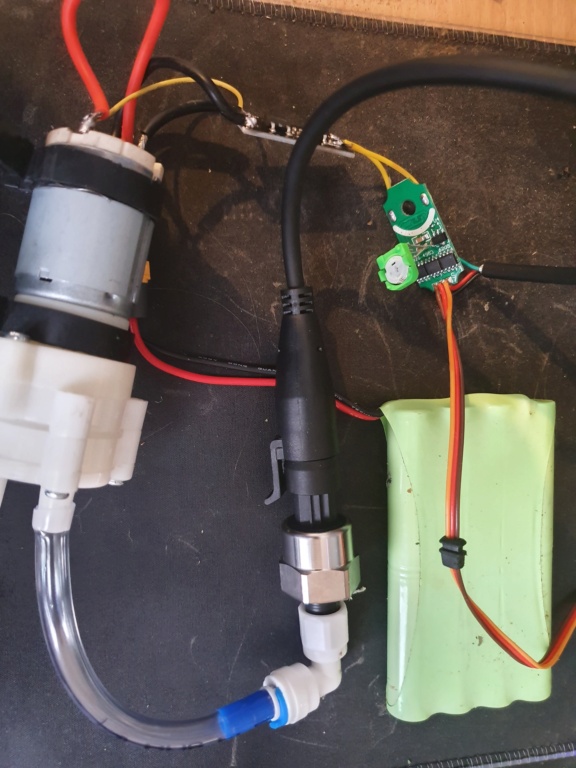

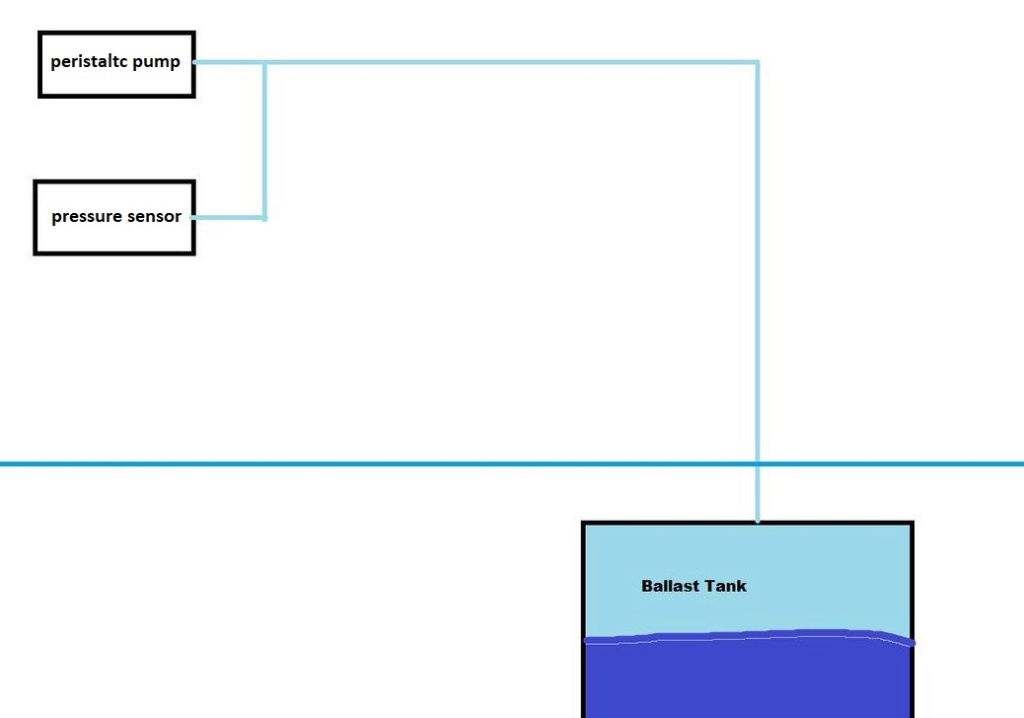

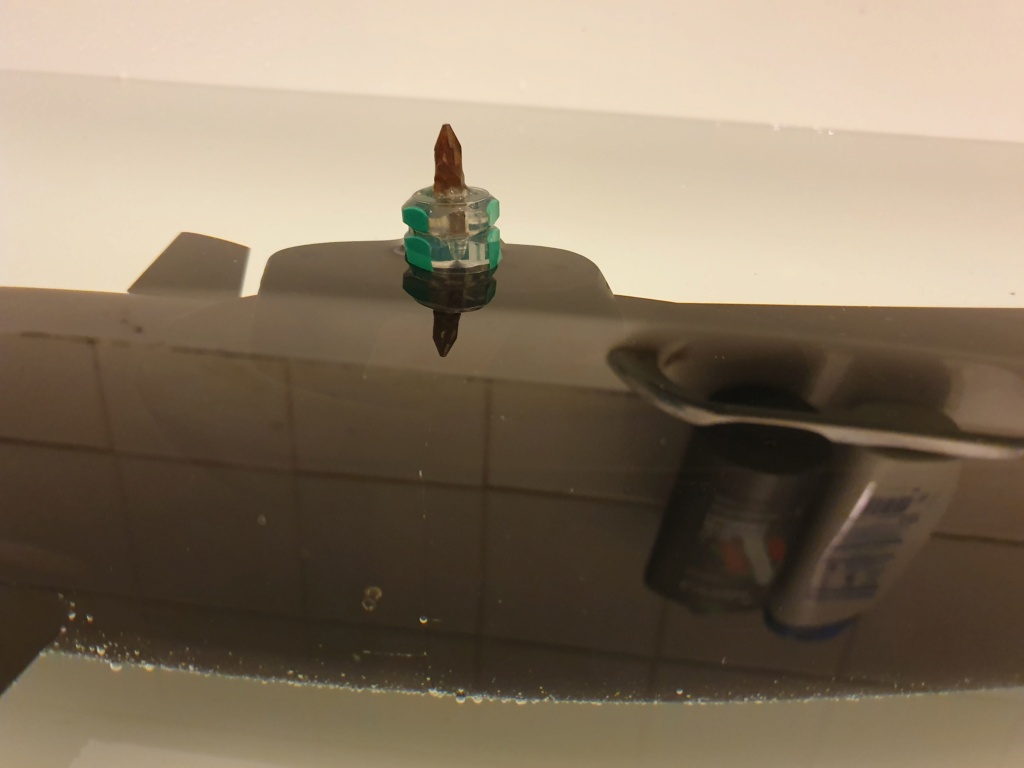

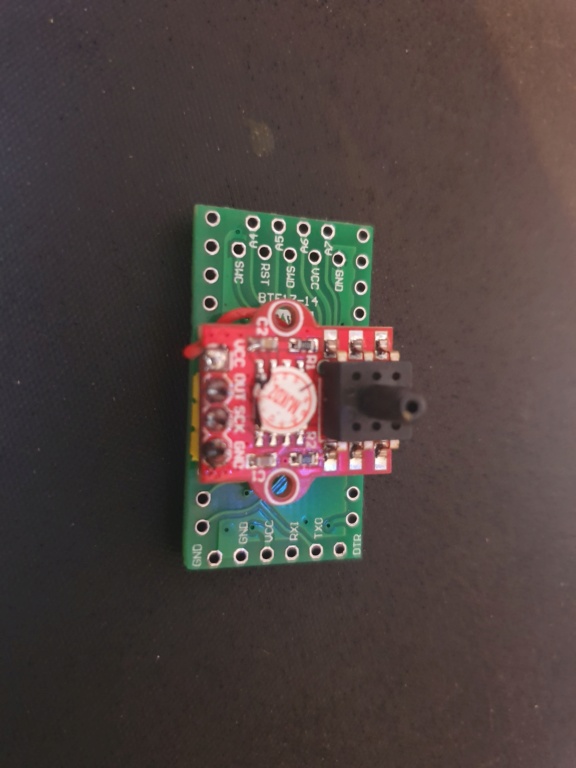

basically the idea is to take the control board from a servo, cut the signal pin to the potentiometer or remove it completely, replace it with an analogue pressure sensor and replace the motor with a 2 way pump. so as far as the servo is concerned its just trying to move the servo horn to a selected position where in reality it should move the sub down until the pressure on the sensor creates a voltage output that matches the position the servo controller is looking for. I have tested it using compressed air on the sensor and the servo motor changes direction to try and compensate for the changing pressure. My next test with be with a test tank and a peristaltic pump to see if it can hold depth.

so in theory 0-100 on the servo input should equal a around 0-3.5 meters using a 5psi sensor. but since they are 5v sensors and the servos operate on 3.3v internally then it will be more like 0-2m without a voltage divider.

This could be scaled up by adding some transistors to the servo letting it operate a 12v pump.

» WW2 mini sub build

» sonar data link

» Robbe Seawolf V2

» ExpressLRS - 868/915 Mhz equipment

» Flight controllers as sub levelers

» 868/915 Mhz as a viable frequency for submarines.

» Futaba -868/915mhz equipment

» Microgyro pitch controller corrosion