x600q90/923/s8OcDE.jpg" />

x600q90/923/s8OcDE.jpg" />

In total there are 26 users online :: 0 Registered, 0 Hidden and 26 Guests

None

Most users ever online was 180 on Tue Nov 05, 2019 6:03 am

Our users have posted a total of 12476 messages in 1986 subjects

We have 1017 registered users

The newest registered user is Bazdiving

x600q90/923/s8OcDE.jpg" />

x600q90/923/s8OcDE.jpg" />

salmon wrote:David,

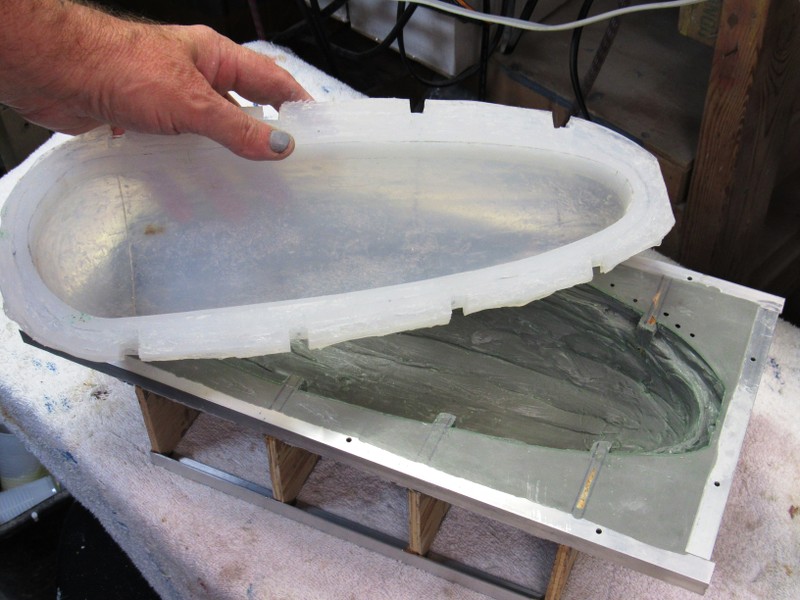

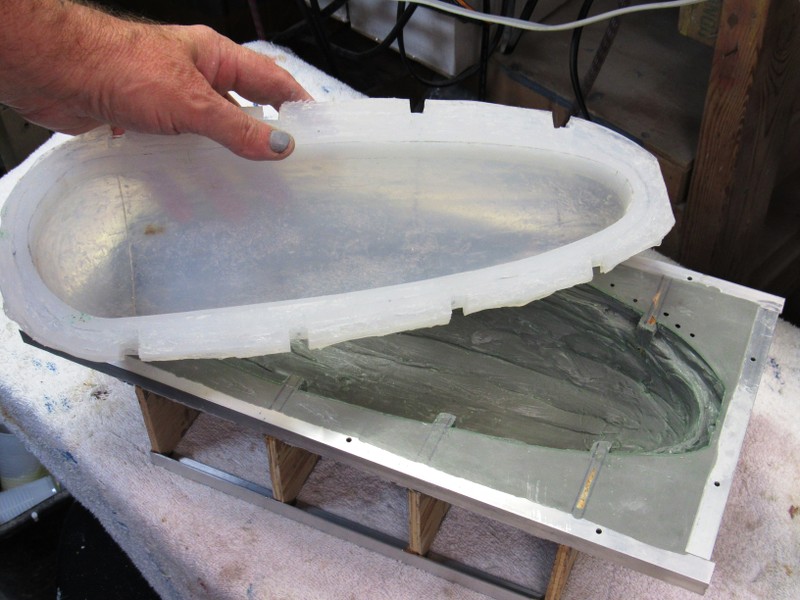

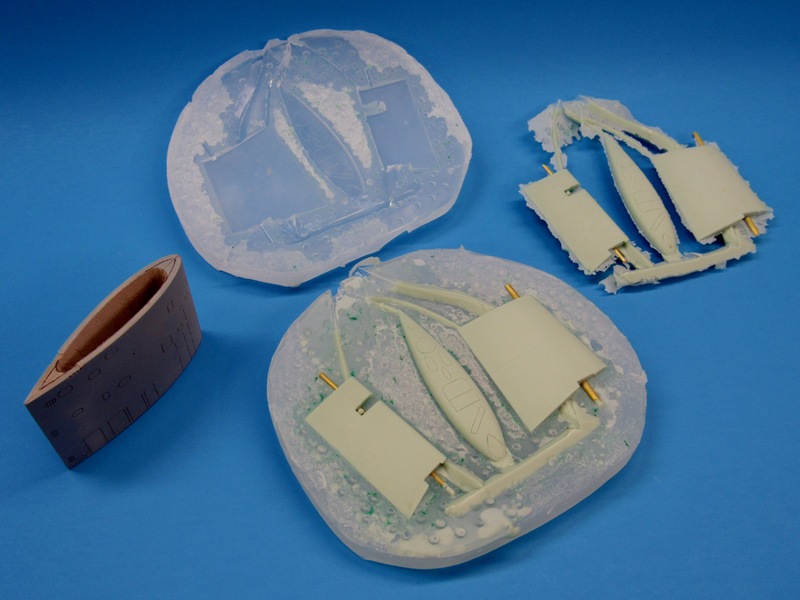

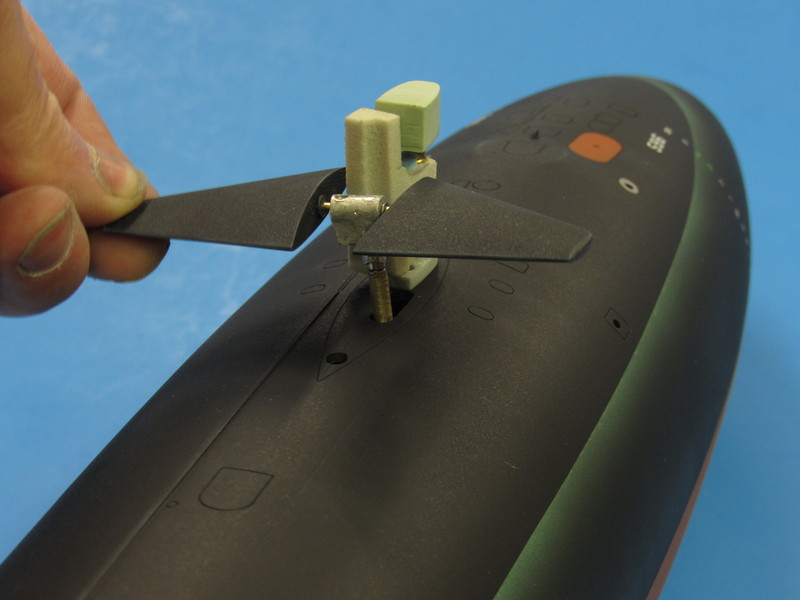

What is the mirror wax used for in that photo of the aft section being molded?

Peace,

Tom

salmon wrote:Thank you for explaining that to me

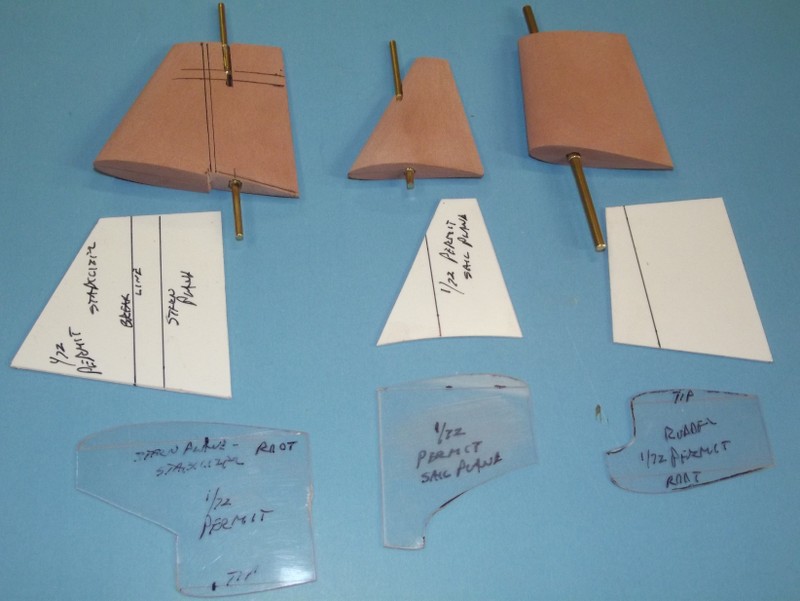

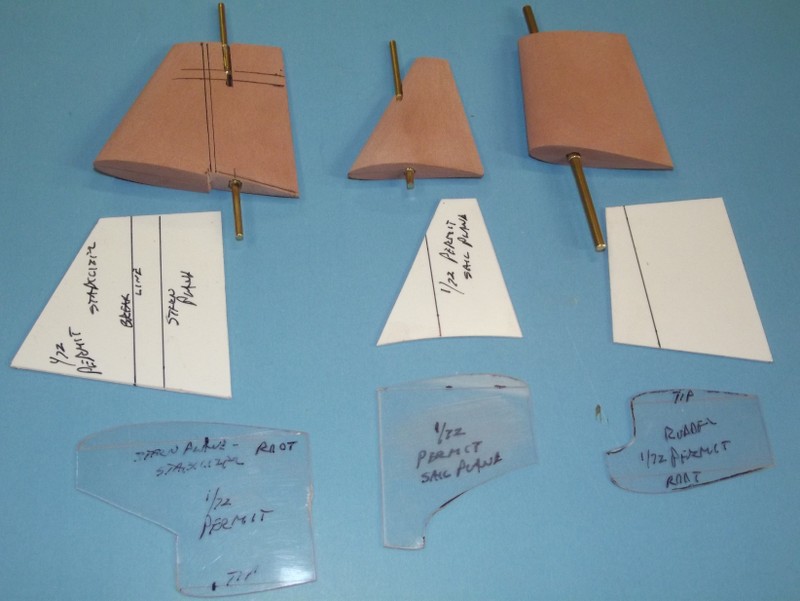

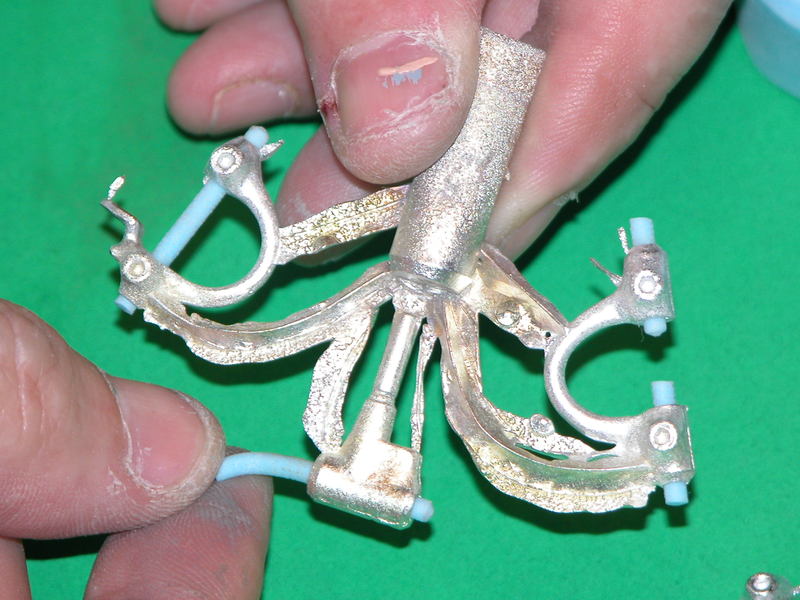

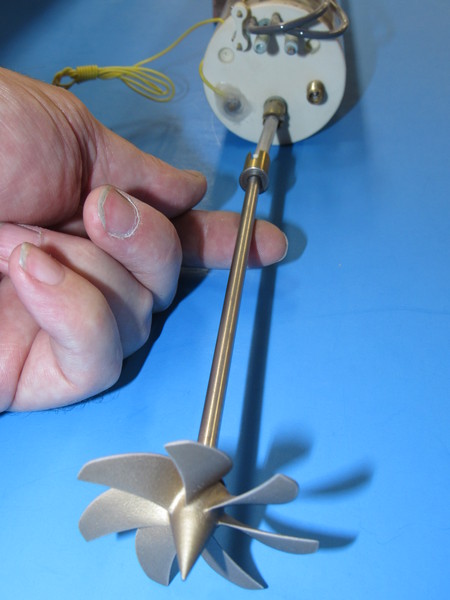

David, when you cast a metal shaft or rod in a piece, what do you do to the metal rod to keep it from sticking to the hardened resin?

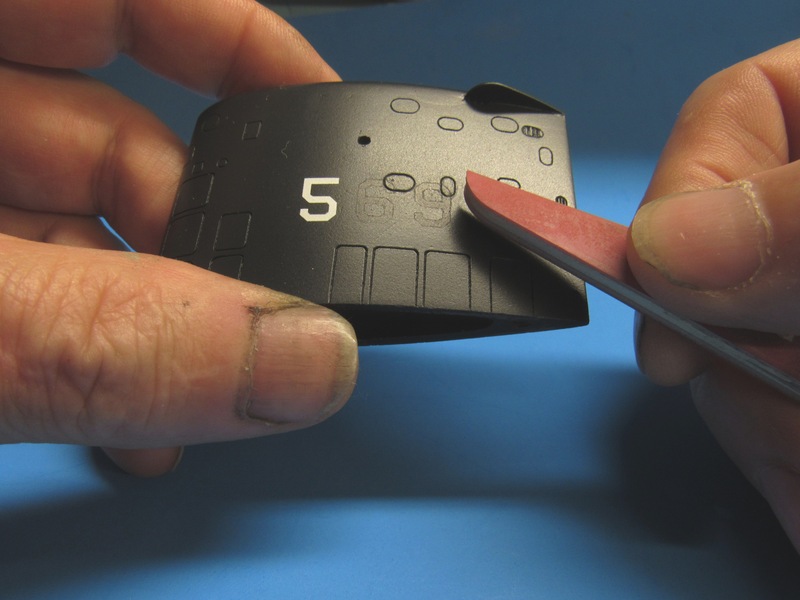

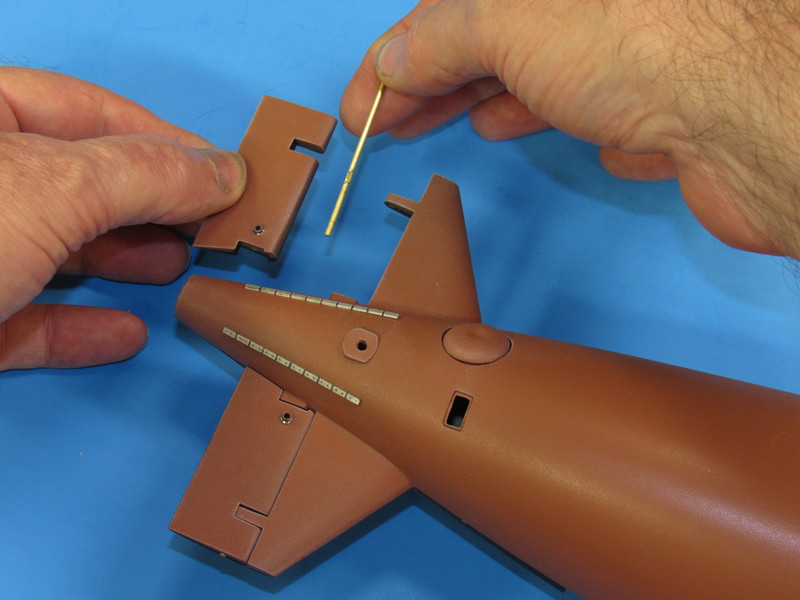

timgarrod wrote:Hi Merriman,

great build log. learning alot from this.

Thanks

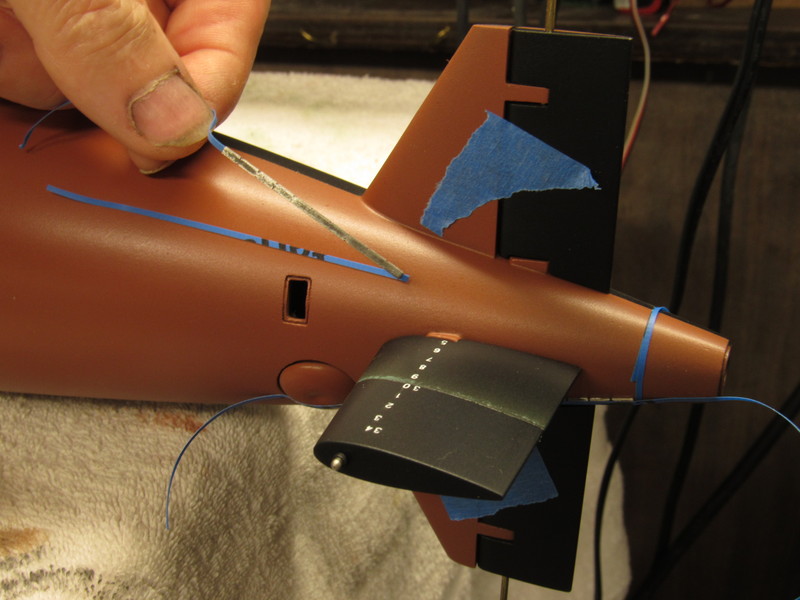

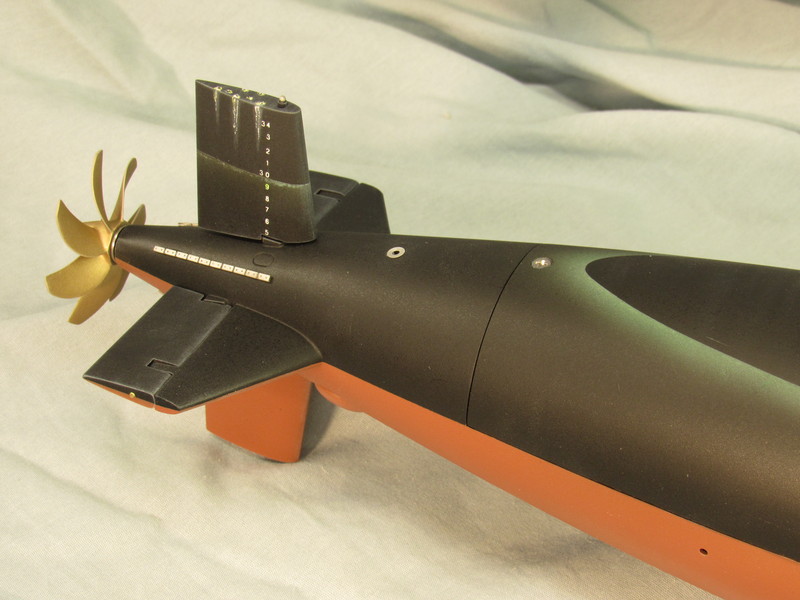

david f wrote:That is beautiful work! Thanks for posting.

David

» Futaba -868/915mhz equipment

» Darnell type 21 submarine, need some help

» Robbe Seawolf V2

» bladder bags

» WW2 mini sub build

» Peral Submarine of 1888

» U-Boat R/C?

» Cheap Arduino Auto leveler