Just done a bit more work on this inspired by Eric Weber's work on the SubCommittee Forum.

Eric's hardware choice works nicely and it is ready built from an eBay supplier, so no need for a soldering iron!

The software, as shown, works with a Hall Switch to count revs and has a failsafe. The piston tank is protected by limit switches - I prefer the separate circuit for this with diodes across the switches, as shown in Norbert Bruggen's book.

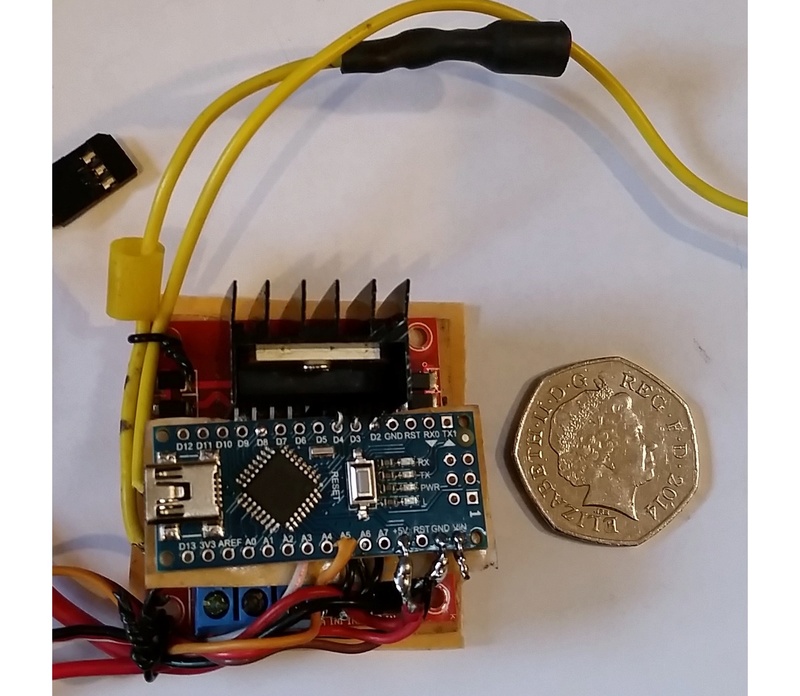

I am quite a convert to the Arduino, by the way. My original routine using PICs took about a year to get going. This version on the Arduino - not much time spent over 2 months. It uses an Arduino Nano - my favourite.

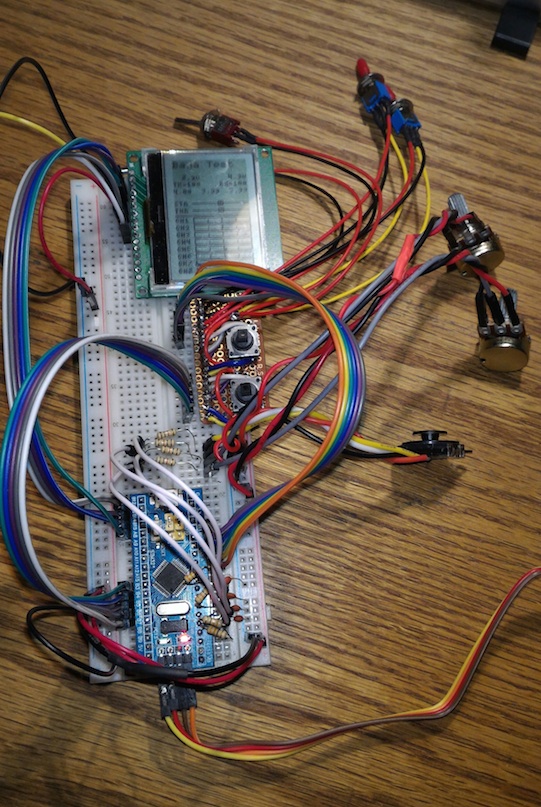

Some health warnings this version has only worked on the bench, so far, not yet in a model submarine. Use it at your own risk.

A short video showing the controller working with a home made piston tank built for my Nordenfelt subs.

https://www.youtube.com/watch?v=fFd_BKnzCe4&t=102s

The software is best downloaded from my site on Github (my first attempts at this!):

https://github.com/rdforrest/submarine-proportional-pistontank/blob/piston-tank/New_Piston4e.ino

The sketch follows but you are best going to the Github:

/*

Proportional Piston Tank Controller by David Forrest based on work by Eric Weber and Gabriel Staples. 24/10/2017

My code changes are labelled RDF. This version New_Piston4e (5/12/2017)

Hall switch (A1104 from Allegro) used to count revolutions and give proportional control.

An error signal is generated from the Hall switch count and the r/c input pulse.

This is fed to the H bridge and motor (It is a servo really)

When the unit is switched on it has 35 seconds to empty the piston tank and set the switch counter to zero.

Loss of r/c signal (Failsafe) empties the piston tank and resets the switch counter.

The Hall effect sensor is switched on when the south pole of a magnet comes close to the front tapering face of the sensor.

Hall switch needs +5v supply.

Nov 2017 Put pullup in software this seems to eliminate the need for a pullup resistor.

Nov 2017 Built In LED now shows forward & reverse

AnalogSmooth routine not actually used.

Notes by Gabriel Staples

Pulse_reader_w_pin_change_interrupt_singleCh.ino

-read in any pulsing signal on Arduino pin INPUT_PIN (defined below), to get its period (us) & freq (Hz), with a time resolution of 0.5us

--you can read in any pulse, including standard PWM signals, Radio Control (RC) PWM signals, etc.

-I am using some low-level AVR code, which requires using some built-in Arduino macros to do pin-mapping.

-this code only reads in a single channel at a time, though it could be expanded to read in signals on every Arduino pin, digital and analog, simultaneously.

--this would be lots of work, so for now I'll leave that up to you.

-this code should be able to read in any pulse between approximately 10~20us and 35.79 minutes; I'll let you experiment

to find the actual shortest pulse you can measure with it

By Gabriel Staples

http://www.ElectricRCAircraftGuy.com/

-My contact info is available by clicking the "Contact Me" tab at the top of my website.

Written: 28 Nov. 2013

Updated: 21 March 2015

Some References:

-to learn how to manipulate some of the low-level AVR code, pin change interrupts, etc, these links will help

--http://www.gammon.com.au/interrupts

--ATmega328 datasheet: http://www.atmel.com/Images/Atmel-8271-8-bit-AVR-Microcontroller-ATmega48A-48PA-88A-88PA-168A-168PA-328-328P_datasheet.pdf

--http://playground.arduino.cc/Main/TimerPWMCheatsheet

--See the *many* very helpful links at bottom of this article: http://www.electricrcaircraftguy.com/2014/01/the-power-of-arduino.html

--reference the Arduino source code, ex:

---C:\Program Files (x86)\Arduino\hardware\arduino\avr\cores\arduino\Arduino.h

---C:\Program Files (x86)\Arduino\hardware\arduino\avr\cores\arduino\wiring_digital.c

---C:\Program Files (x86)\Arduino\hardware\arduino\avr\variants\standard\pins_arduino.h

*/

/*

Circuits:

Option 1) To measure the pulses from an Arduino PWM pin, ex: pin 5 or 9, connect Pin 5 or 9 (a PWM output) to INPUT_PIN (the pulse reader input)

-see the setup() function for commanding the PWM output to begin, so you can have something to read in

Option 2) To measure an RC PWM servo-type signal coming from an RC Rx:

-Power the Rx by connecting 5V to + on the Rx, and GND to - on the Rx

-Connect the channel signal you want to measure on the Rx to the INPUT_PIN on the Arduino

*/

#include <AnalogSmooth.h>

/*

Smooths signal jitter on analog inputs by averaging

concurrent readings. The number of readings averaged can

range from 1 (no smooting) to 100.

The more readings you average the more consistent the signal

becomes. At the same time it takes longer to detect actual

changes in the signal.

*/

#include <eRCaGuy_Timer2_Counter.h>

//#include <avr/wdt.h> // Include watch dog timer

//macros

#define fastDigitalRead(p_inputRegister, bitMask) ((*p_inputRegister & bitMask) ? HIGH : LOW)

//Global Variables & defines

const byte INPUT_PIN = A5; //RDF changed to A5 .you can change this to ANY digital or analog pin, ex: 10, 8, A0, A5, etc,

//EXCEPT A6 and A7 (which exists on the Nano and Pro Mini, for example, and are NOT capable of digital operations)

byte input_pin_bitMask;

volatile byte* p_input_pin_register;

//volatile variables for use in the ISR (Interrupt Service Routine)

volatile boolean output_data = false; //the main loop will try to output data each time a new pulse comes in, which is when this gets set true

volatile unsigned long pulseCounts = 0; //units of 0.5us; the input signal high pulse time

volatile unsigned int pd = 0; //units of 0.5us; the pulse period (ie: time from start of high pulse to start of next high pulse)

// Simple counter from below (RDF)

int ip_pulse = 0; // Variable from TX pulse by RDF

int errsig = 0; // Error signal for servo action (Hall count minus PWM input)

//https://quarkstream.wordpress.com/2009/12/11/arduino-4-counting-events/

int state = LOW;

int lastState = LOW;

int count = 0;

int reverse = 15;

int failsafe_count = 1;

//Digital input pin 8 for Hall switch input.

unsigned long duration;

int analog = errsig ;

float analogSmooth;

// Defaults to window size 10

AnalogSmooth as = AnalogSmooth();

// Window size can range from 1 - 100

AnalogSmooth as100 = AnalogSmooth(100);

void setup() {

// put your setup code here, to run once:

pinMode(8, INPUT_PULLUP);// Put Pullup on Hall switch input

state = digitalRead(8);

pinMode(INPUT_PIN, INPUT_PULLUP); //use INPUT_PULLUP to keep the pin from floating and jumping around when nothing is connected

//configure timer2

timer2.setup();

//prepare for FAST digital reads on INPUT_PIN, by mapping to the input register (ex: PINB, PINC, or PIND), and creating a bitMask

//using this method, I can do digital reads in approx. 0.148us/reading, rather than using digitalRead, which takes 4.623us/reading (31x speed increase)

input_pin_bitMask = digitalPinToBitMask(INPUT_PIN);

p_input_pin_register = portInputRegister(digitalPinToPort(INPUT_PIN));

configurePinChangeInterrupts();

//start PWM output (to read in its pulses, for use in Circuit 1 as described above)

pinMode(5, OUTPUT);

pinMode(9, OUTPUT);

analogWrite(5, 10); http://976.5625Hz, with high pulses of ~1/976.5625 x 10/256 = 40us; Connect pin 5 to INPUT_PIN and open serial monitor & you will see approximately this

analogWrite(9, 128); http://490.20Hz, with high pulses of ~1/490.2 x 128/256 = ~1020us; Connect pin 9 to INPUT_PIN and open serial monitor & you will see approximately this

/*

PWM Notes:

-PWM on pins 5 & 6 occurs at 976.5625Hz; see here: http://playground.arduino.cc/Main/TimerPWMCheatsheet

-PWM on pins 9 & 10 occurs at 490.20Hz

*/

Serial.begin(9600); //RDF changed from 115200

Serial.print(F("Begin waiting for pulses on pin ")); Serial.print(INPUT_PIN);

Serial.println(F(".\nData will be printed after each pulse is received."));

// Test.connect motor controller pins to Arduino digital pins

// motor one

// https://tronixlabs.com.au/news/tutorial-l298n-dual-motor-controller-module-2a-and-arduino

int enA = 3;

int in1 = 2;

int in2 = 4;

// set all the motor control pins to outputs

pinMode(enA, OUTPUT);

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

//Test. This will be used for piston tank initial setup

digitalWrite(in1, HIGH); //Swap in1 & in2 to reverse motor

digitalWrite(in2, LOW);

digitalWrite(enA, HIGH); //High runs motor

delay(35000); //35 second delay to get piston tank empty from the start.

//set rev counter to zero

count = 0;

// initialize digital pin LED_BUILTIN as an output.

pinMode(LED_BUILTIN, OUTPUT);

// Setup code finishes here

}

void loop() {

// put your main code here, to run repeatedly:

//local variables

static float pulseTime = 0; //us; the most recent input signal high pulse time

static float pd_us = 0; //us; the most recent input signal period between pulses

static float pulseFreq = 0; //Hz, the most recent input signal pulse frequency

if (output_data == true) //if a pulse just came in

{

//turn off interrupts, grab copies of volatile data, and re-enable interrupts

noInterrupts();

output_data = false; //reset

unsigned long pulseCountsCopy = pulseCounts; http://0.5us units

unsigned long pdCopy = pd; http://0.5us units

interrupts();

//do calculations

pulseTime = pulseCountsCopy / 2.0; //us

pd_us = pdCopy / 2.0; //us

pulseFreq = 1000000.0 / pd_us; //Hz

//failsafe_count = ++failsafe_count; //Increment failsafe count by RDF

//if ( pulseTime > 1000 ) {

// failsafe_count = 0; // set counter to zero if pulses are > 1000

// }

//print values

//(optionally, add extra code here to not print after EVERY pulse is received, as this can result in serial data coming in excessively fast when pulses come in at a high freq)

//Serial.print(F("pulsetime(us) = ")); Serial.print(pulseTime);

//Serial.print(F(", pd_us(us) = ")); Serial.print(pd_us);

//Serial.print(F(", pulseFreq(Hz) = ")); Serial.println(pulseFreq);

Serial.print(F(" Hall Count=")); Serial.println(count);

Serial.print(F("IP Pulse=")); Serial.print(ip_pulse);

//Serial.print(F("Error signal = ")); Serial.print(errsig);

//Serial.print(F("reverse = ")); Serial.print(reverse);

//Serial.print(F("Failsafe = ")); Serial.print(failsafe_count);

// Hall switch counter, with increment/decrement depending on direction of rotation by RDF

int enA = 3;

int in1 = 2;

int in2 = 4;

if (state == HIGH && lastState == LOW) {

// if (reverse > 0 ) { ++count; } else { --count; }

if (reverse > 0 ) {

--count;

} else {

++count;

}

}

lastState = state;

state = digitalRead(8);

}

// Calculations here

ip_pulse = (((pulseTime - 1005) / 7) - 20); // For a screw length of about 250 revs. 25 is stick trim factor

//AnalogSmooth section not used and commented out

//int analog = ip_pulse; // put ip_pulse into AnalogSmooth

// Defaults to window size 10

//AnalogSmooth as = AnalogSmooth();

//int analogSmooth = as.smooth(analog);

//ip_pulse = analogSmooth;

errsig = count - ip_pulse;

// Testing motor output pins

int enA = 3;

int in1 = 2;

int in2 = 4;

// If errsig is negative, reverse the motor

if (errsig < 0) {

digitalWrite(in1, LOW); //Swap in1 & in2 to reverse motor

digitalWrite(LED_BUILTIN, HIGH); // turn the Built In LED on (HIGH is the voltage level)

digitalWrite(in2, HIGH);

digitalWrite(enA, HIGH); //High runs motor

reverse = -7;

}

// If absolute value of errsig is less than 20, stop the motor

if ((errsig < 10) && (errsig > -10))

{

digitalWrite(in1, HIGH); //Swap in1 & in2 to reverse motor

digitalWrite(in2, LOW);

digitalWrite(enA, LOW); //High runs motor

reverse = 2;

}

//Set motor to forward

if (errsig > 0) {

digitalWrite(in1, HIGH); //Swap in1 & in2 to reverse motor

digitalWrite(LED_BUILTIN, LOW); // turn the Built In LED off(HIGH is the voltage level)

digitalWrite(in2, LOW);

digitalWrite(enA, HIGH); //High runs motor

reverse = 8;

}

// If Failsafe triggered - set piston to empty

if ((pulseFreq > 53) || (pulseFreq < 49) && (failsafe_count > 1000))

{

failsafe_count = ++failsafe_count; //Increment failsafe count by RDF

//Failsafe routine (like piston tank initial setup.)

digitalWrite(in1, HIGH); //Swap in1 & in2 to reverse motor

digitalWrite(in2, LOW);

digitalWrite(enA, HIGH); //High runs motor

delay(35000); //35 second delay to get piston tank empty.

//set rev counter to zero

count = 0;

digitalWrite(in1, HIGH); //Swap in1 & in2 to reverse motor

digitalWrite(in2, LOW);

digitalWrite(enA, HIGH); //High runs motor

Serial.print(F("Failsafe = ")); Serial.print(pulseFreq);

}

//else {failsafe_count = 0;

//}

} //end of loop()

////Use macro instead

//boolean fastDigitalRead(volatile byte* p_inputRegister,byte bitMask)

//{

// return (*p_inputRegister & bitMask) ? HIGH : LOW;

//}

void pinChangeIntISR()

{

//local variables

static boolean pin_state_new = LOW; //initialize

static boolean pin_state_old = LOW; //initialize

static unsigned long t_start = 0; //units of 0.5us

static unsigned long t_start_old = 0; //units of 0.5us

pin_state_new = fastDigitalRead(p_input_pin_register, input_pin_bitMask);

if (pin_state_old != pin_state_new)

{

//if the pin state actualy changed, & it was not just noise lasting < ~2~4us

pin_state_old = pin_state_new; //update the state

if (pin_state_new == HIGH)

{

t_start = timer2.get_count(); http://0.5us units

pd = t_start - t_start_old; http://0.5us units, the incoming pulse period

t_start_old = t_start; http://0.5us units; update

}

else //pin_state_new == LOW

{

unsigned long t_end = timer2.get_count(); http://0.5us units

pulseCounts = t_end - t_start; http://0.5us units

output_data = true;

}

}

}

//Interrupt Service Routines (ISRs) for Pin Change Interrupts

//see here: http://www.gammon.com.au/interrupts

//PCINT0_vect is for pins D8 to D13

ISR(PCINT0_vect)

{

pinChangeIntISR();

}

//PCINT1_vect is for pins A0 to A5

ISR(PCINT1_vect)

{

pinChangeIntISR();

}

//PCINT2_vect is for pins D0 to D7

ISR(PCINT2_vect)

{

pinChangeIntISR();

}

void configurePinChangeInterrupts()

{

//Pin Change Interrupt Configuration

//see ATmega328 datasheet, ex: pgs. 73-75

//also see: C:\Program Files (x86)\Arduino\hardware\arduino\avr\variants\standard\pins_arduino.h for the macros used here

//1st, set flags on the proper Pin Change Mask Register (PCMSK)

volatile byte* p_PCMSK = (volatile byte*)digitalPinToPCMSK(INPUT_PIN); //pointer to the proper PCMSK register

*p_PCMSK = _BV(digitalPinToPCMSKbit(INPUT_PIN));

//2nd, set flags in the Pin Change Interrupt Control Register (PCICR)

volatile byte* p_PCICR = (volatile byte*)digitalPinToPCICR(INPUT_PIN); //pointer to PCICR

*p_PCICR |= _BV(digitalPinToPCICRbit(INPUT_PIN));

// //ex: to use digital pin 8 as the INPUT_PIN:

// //turn on PCINT0_vect Pin Change Interrupts (for pins D8 to D13); see datasheet pg. 73-75.

// //1st, set flags on the proper Pin Change Mask Register

// PCMSK0 = 0b00000001; //here I am setting Bit0 to a 1, to mark pin D8's pin change register as on; for pin mapping see here: http://arduino.cc/en/Hacking/PinMapping168

// //2nd, set flags in the Pin Change Interrupt Control Register

// PCICR |= 0b00000001; //here I am turning on the pin change vector 0 interrupt, for PCINT0_vect, by setting the right-most bit to a 1

}

» Futaba -868/915mhz equipment

» Darnell type 21 submarine, need some help

» Robbe Seawolf V2

» bladder bags

» WW2 mini sub build

» Peral Submarine of 1888

» U-Boat R/C?

» Cheap Arduino Auto leveler