among my papers I have found an article that I had written in 1995 for a German ship modeller Magazine. As it may be of some interest for you I have started to translate it into English (please excuse my poor English) and will post it time by time.

Here is the first item:

The Hermatically Sealed Model Submarine

Story of a model submarine of the German class 206A submarine S195 / U16

Preface

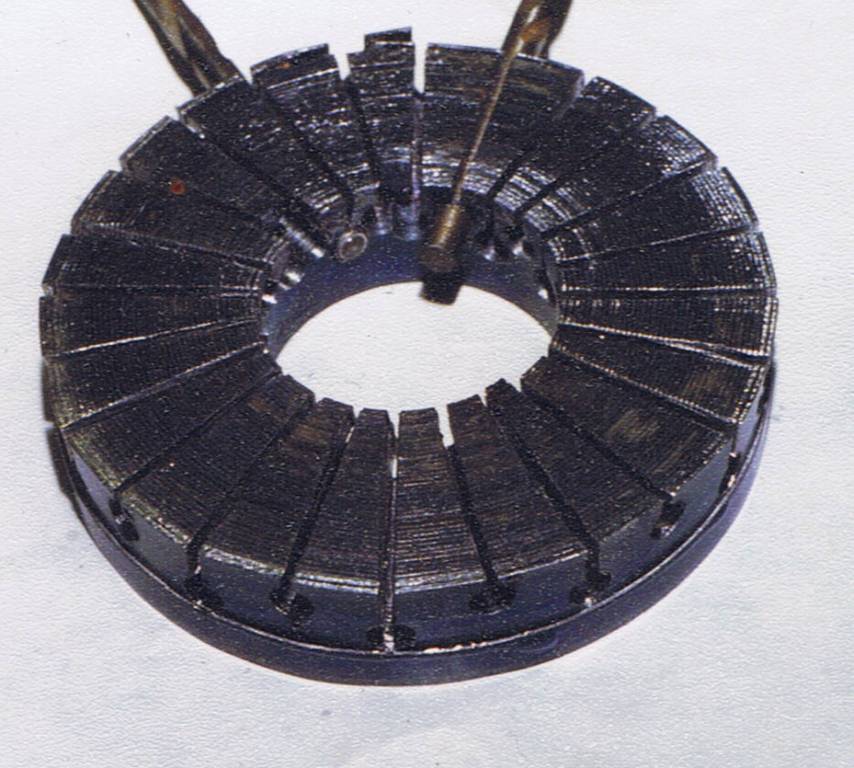

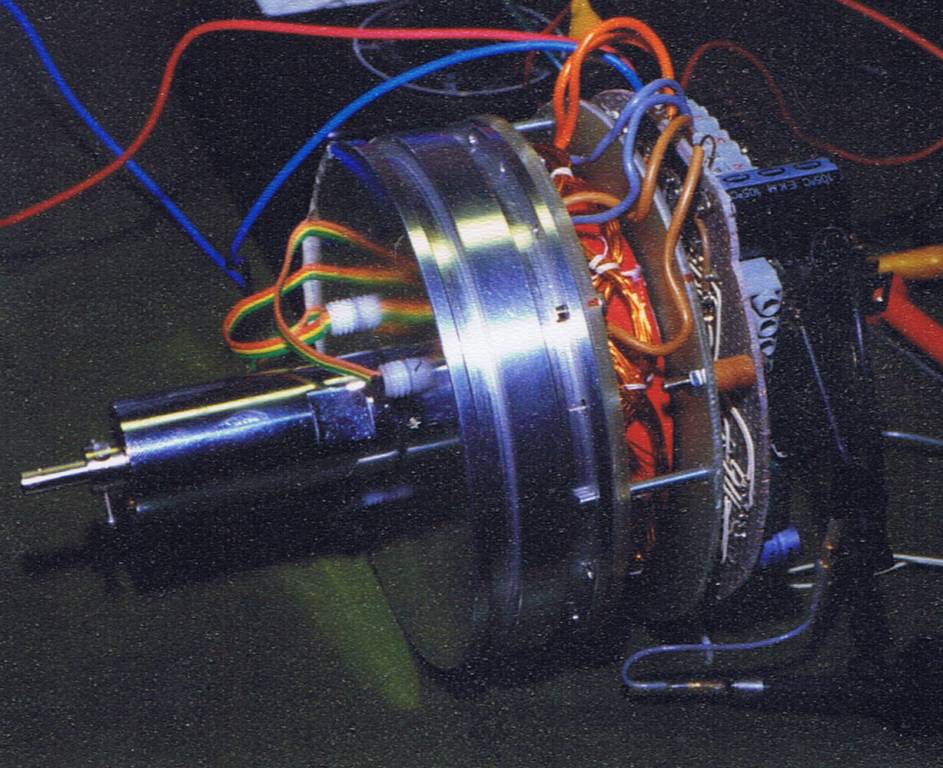

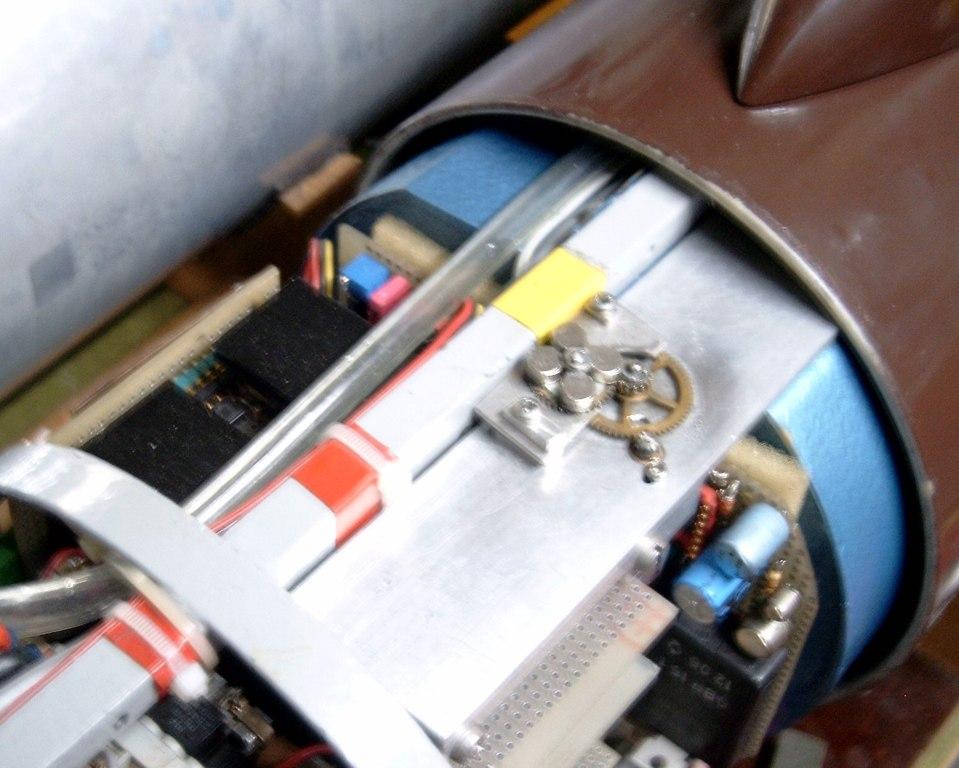

This is the story of an unusual model submarine that I started to build in 1976, rebuilding it in the early 1990ies and that is "in service" since 1994 up to now. As the title claims it is hermetically tight by its design concept - we will see later what this means in details. This model is one of the first submarine models with an electronically commutated ("brushless"), wet running DC motor (if not the very first) and is the precursor of my aluminium model S182 / U32 of the recent class 212A of the German Navy that was described in a guest article in one of the latest issues of the AMS "In Depth" magazine.

How it begun...

The story begun in 1975 when a ship modeller friend showed me a poster of one of the first class 205 submarines of the German Navy. As I already had had the wish to build a model submarine but did not like the World War II types very much I just made up my mind to build this (at this time still modern) type.

The class 205 was the first submarine type of the young Federal German Navy to be built in greater numbers and it were the first to be built with hulls made of non magnetic (stainless) steel to enable them to operate also in shallow waters where mines meant even more a potential danger. In the cold war in these times the were intended mainly to operate in the Baltic Sea. The were rather small, about 500 tons displacement but carrying 8 torpedo tubes in the bow.

The first batch became a disaster soon - although extended investigations on nonmagnetic steel had been made before building, the steel of the hulls began to corrode internally (as later detected as inter- crystalline stress rupture corrosion). So after a few years the submarines were decommisioned for safety reasons. Some years later in the mid 1970ies, the type 206 was built, now with better and corrosion-resistant steel. This class, modernised at the end of the 1980ies as class 206A, was in service for more than 30 years until they were replaced by the class 212A with air independent propulsion system by fuel cells . The rather small class 206A submarines, about 500 tons displacement, 48 metres in length and with a crew of 22, were the first German submarines that crossed the Atlantic Ocean again to join NATO exercises in the Caribbean Sea and to make goodwill visits to the US.

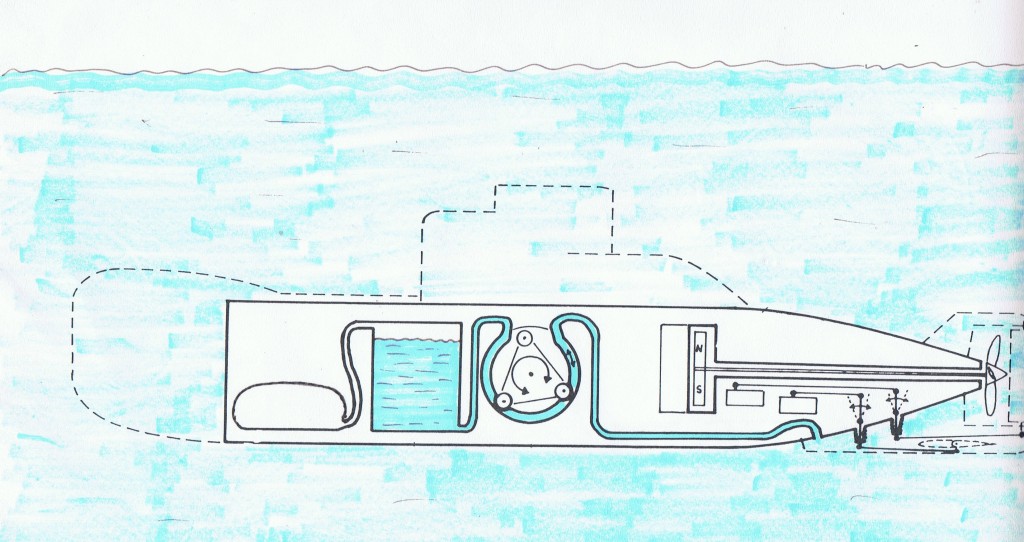

Another reason to build a model of the class 205 was that it was well suited to be built with a plastic tube as pressure hull and a technics rack insert for radio control, propulsion system and diving system and the batteries. Bow and stern sections could be made of GRP laminates, the conning tower of polystyrene plastic sheet material. This design offered a splendid access to the interior and provided a good structure stability of the hull as well as good conditions for pressure tightness by only a few O-ring seals.

I had seen submarine models with their hulls covered by hatches with "thousands of screws" and I wanted to avoid this design with its inherent drawbacks under all circumstances.

To get sufficient space inside I planned to use a plastic sewers tube of 160mm outside diameter. To fit into the boot of my car I drove as a student those days (a FIAT 127 , I still have this car preserved as a classic car now) the model should not be longer than 125 centimetres so the proportions would be a little compressed.

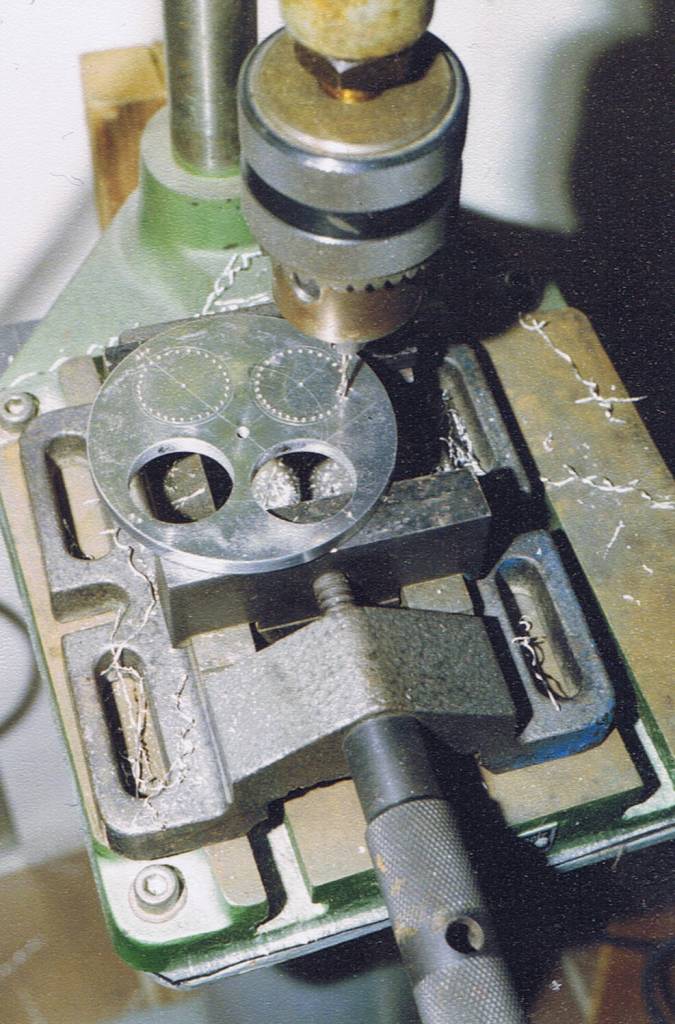

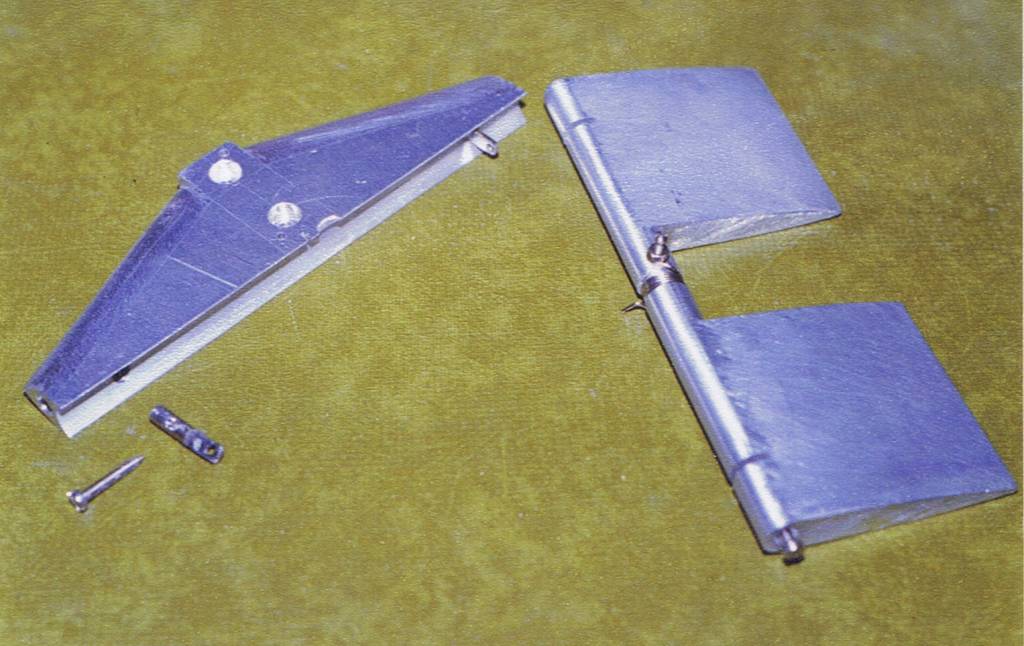

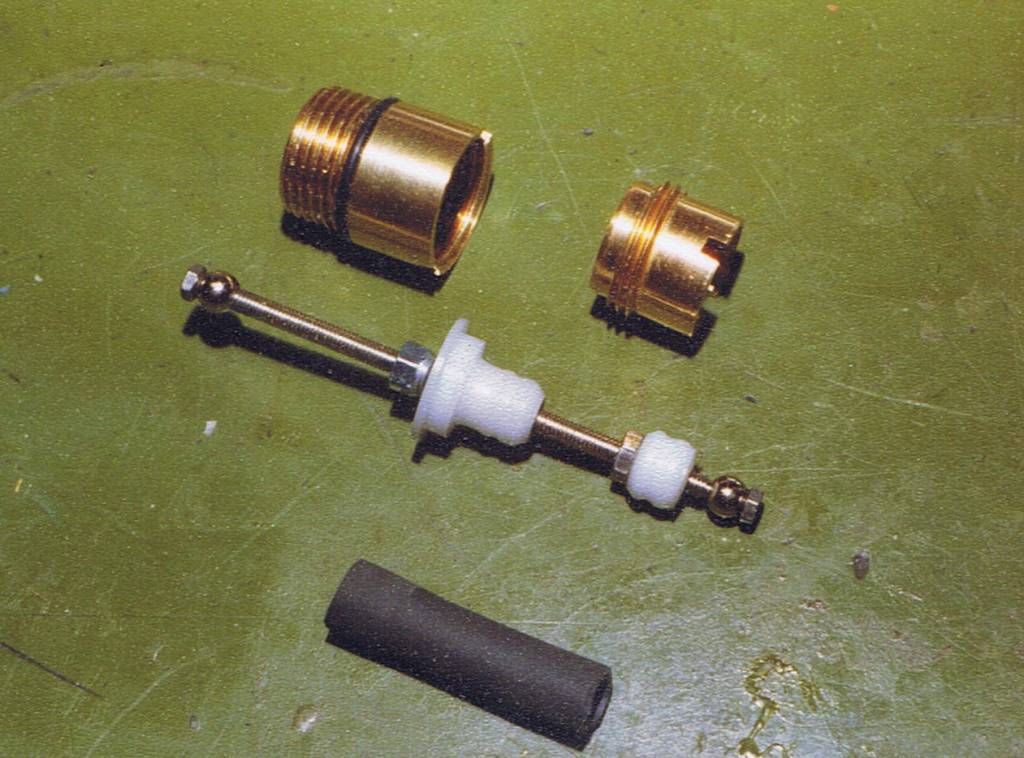

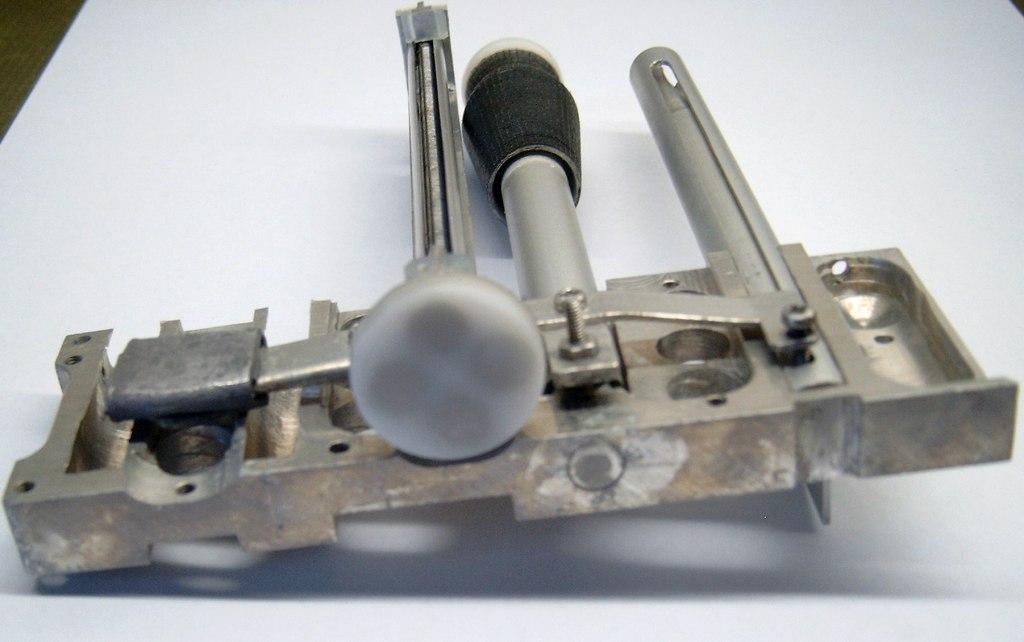

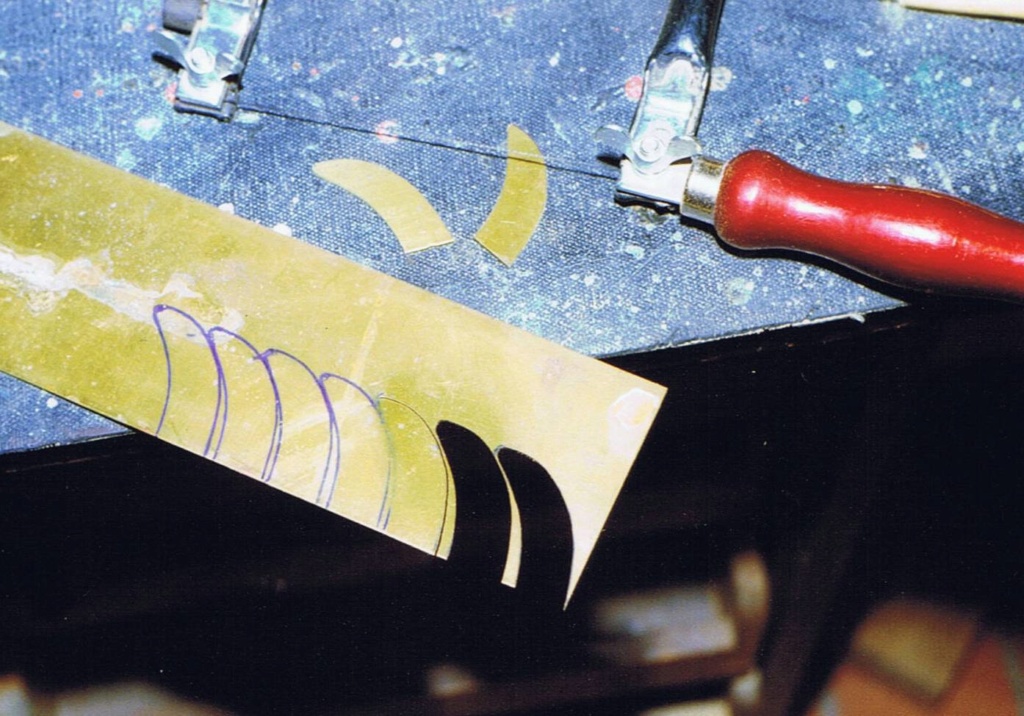

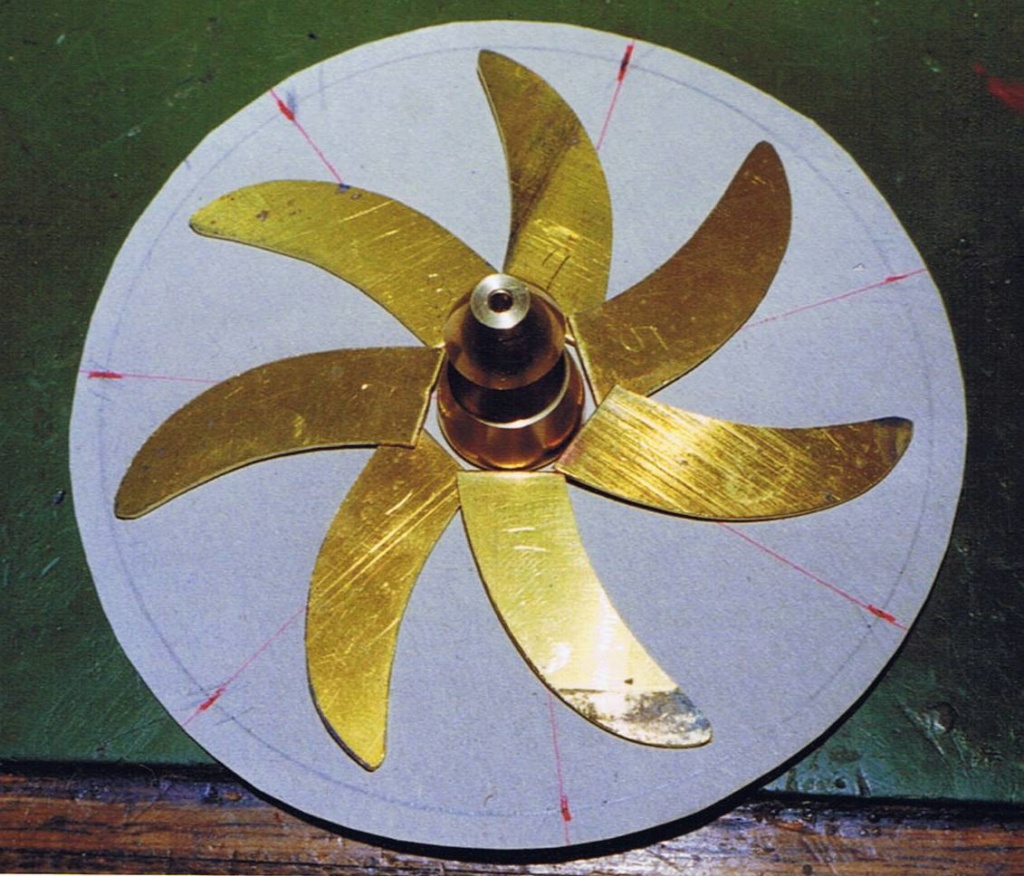

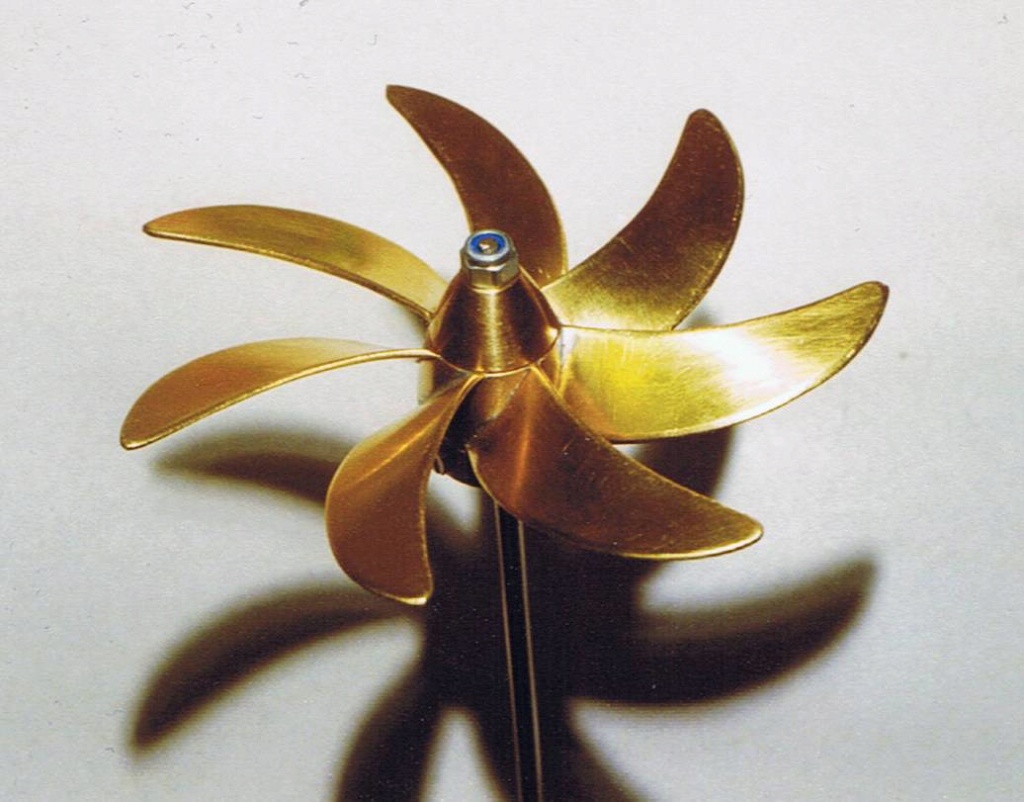

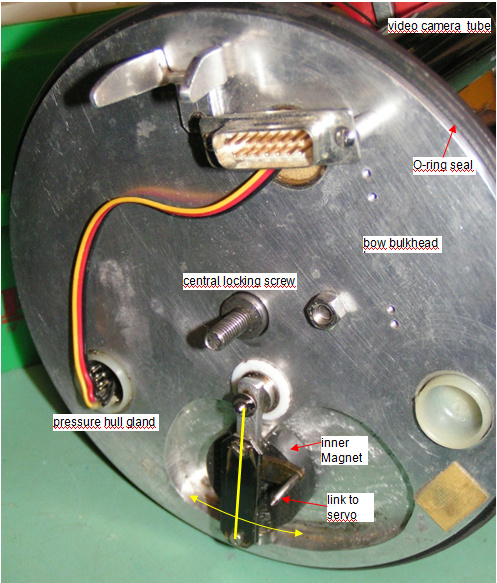

I designed the internal technics rack as a framework of three 10mm x 10mm steel rods hard solderer together with ring ribs made of 10mm x 2mm flat steel. This framework should extend from the end of the stern with the propeller tube up to the bow bulkhead where the cylindrical section ends. The conical rear section of the hull should be fixed to the frame and the tube should be shifted over the frame just to the beginning of the conical section. There an O-ring seal should provide tightness. The front end of the tube should be covered with a circular aluminium bulkhead plate also equipped with an O-ring seal. Tube and bulkhead should be screwed to the frame by a screw penetrating the bulkhead in the centre and sealed there and going further into a thread in the frame. The bow should be free flooded and attached to the bulkhead. The rudders were designed to be made of brass sheet material and the diving system should consist of a ballast tank made of brass sheet metal to be filled by a hose pipe roller pump.

....(to be continued)

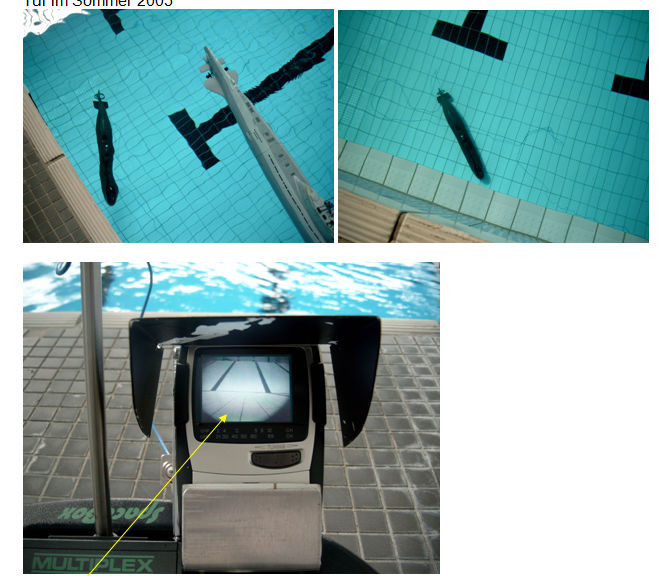

As the model looks today...

Last edited by Hermann on Wed Feb 25, 2015 9:53 pm; edited 1 time in total (Reason for editing : adding a picture)

» Futaba -868/915mhz equipment

» Darnell type 21 submarine, need some help

» Robbe Seawolf V2

» bladder bags

» WW2 mini sub build

» Peral Submarine of 1888

» U-Boat R/C?

» Cheap Arduino Auto leveler