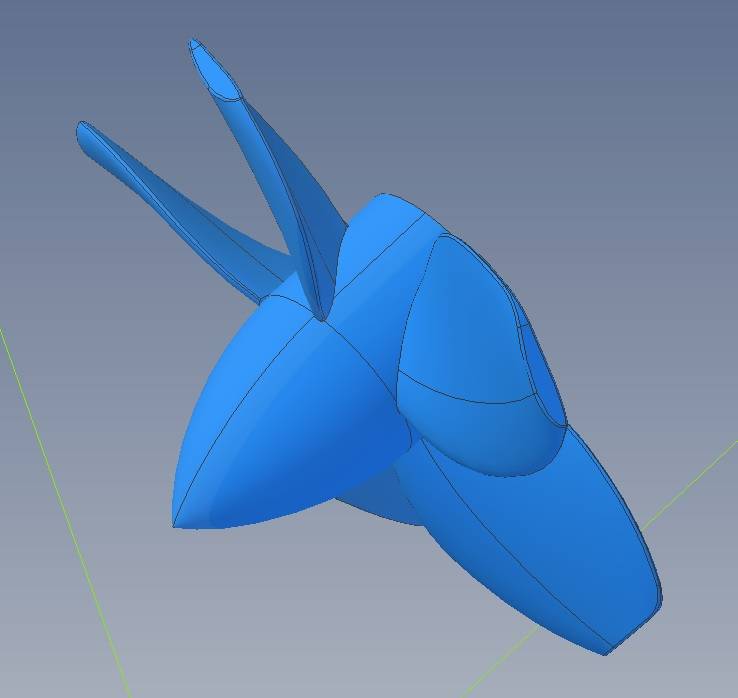

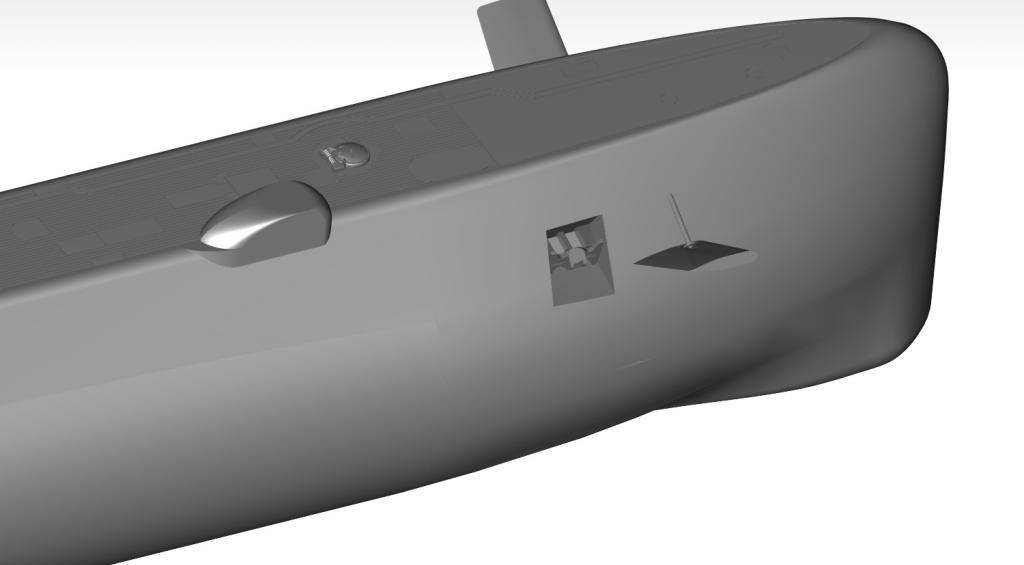

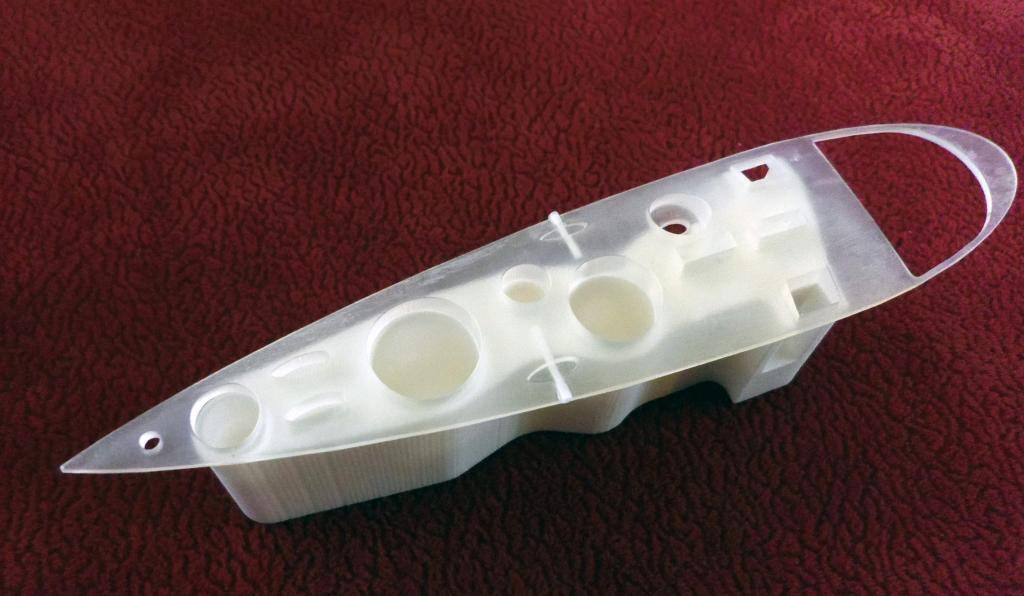

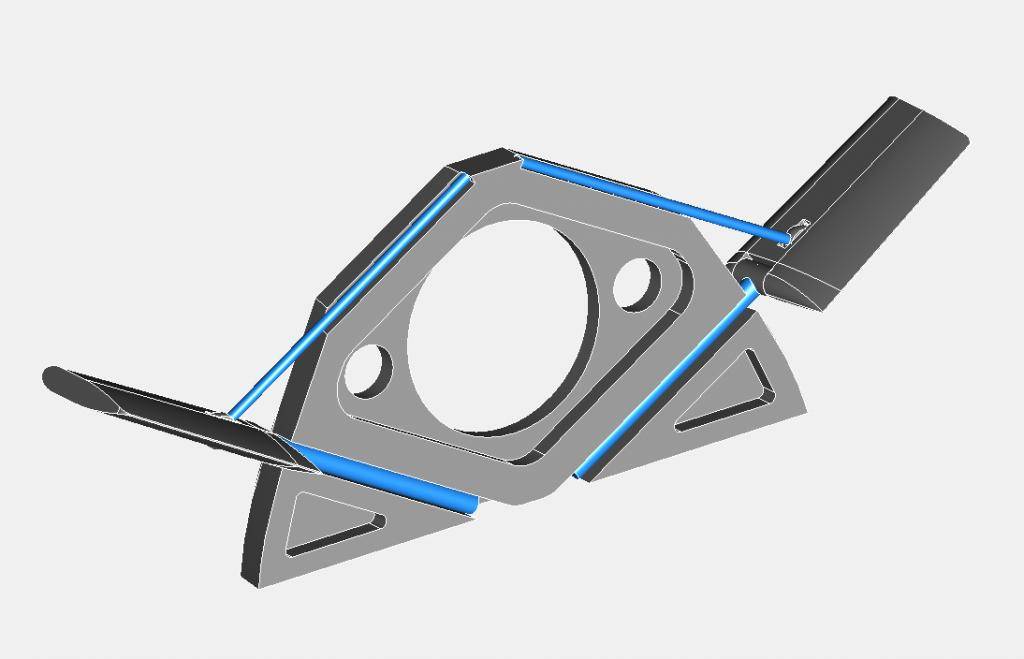

The future - we'll just download a CAD/CAM file?

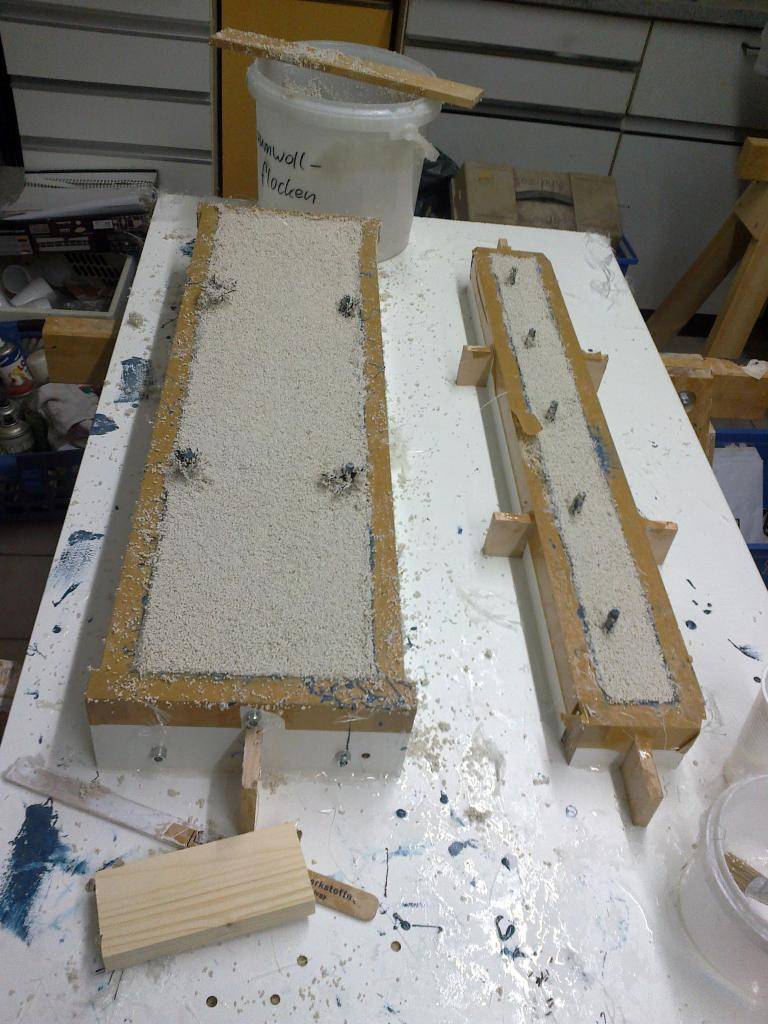

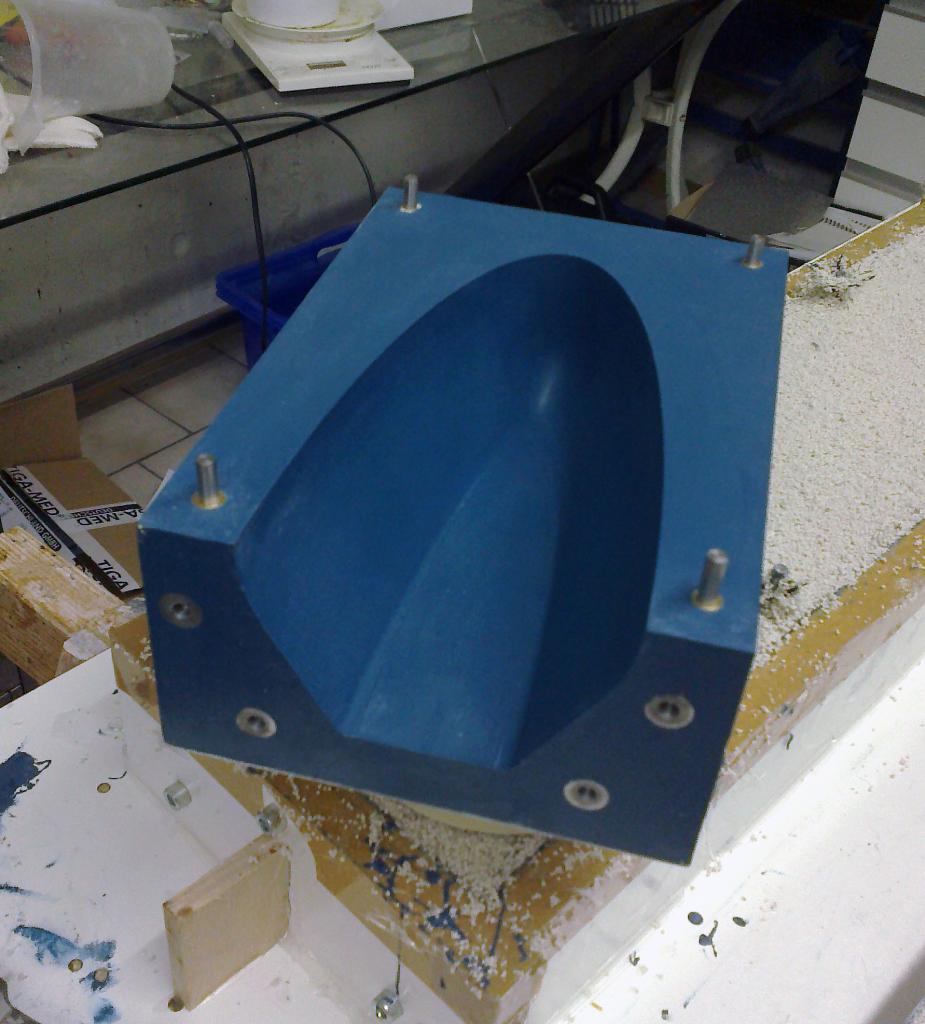

From our previous discussions, the only remaining problem seems to be the cost and availabilty of the fabrication stage?

David

BTW Andreas - I see that you are still a Guest. You can join the AMS now. Just click the link and it's free.

» Futaba -868/915mhz equipment

» Darnell type 21 submarine, need some help

» Robbe Seawolf V2

» bladder bags

» WW2 mini sub build

» Peral Submarine of 1888

» U-Boat R/C?

» Cheap Arduino Auto leveler