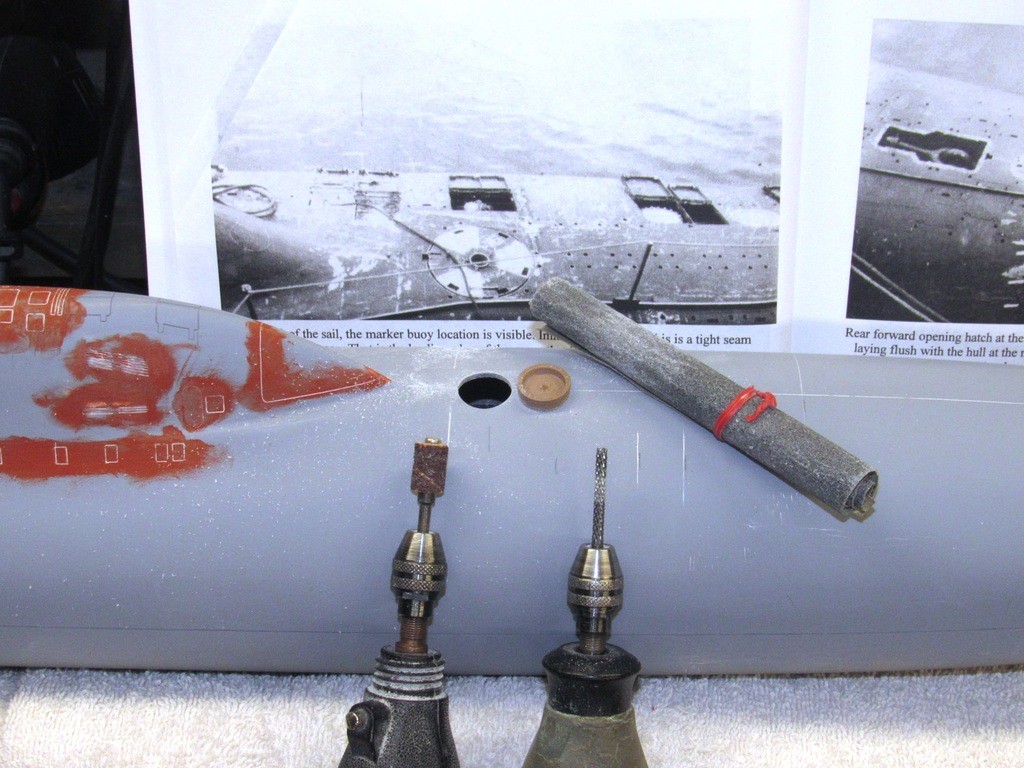

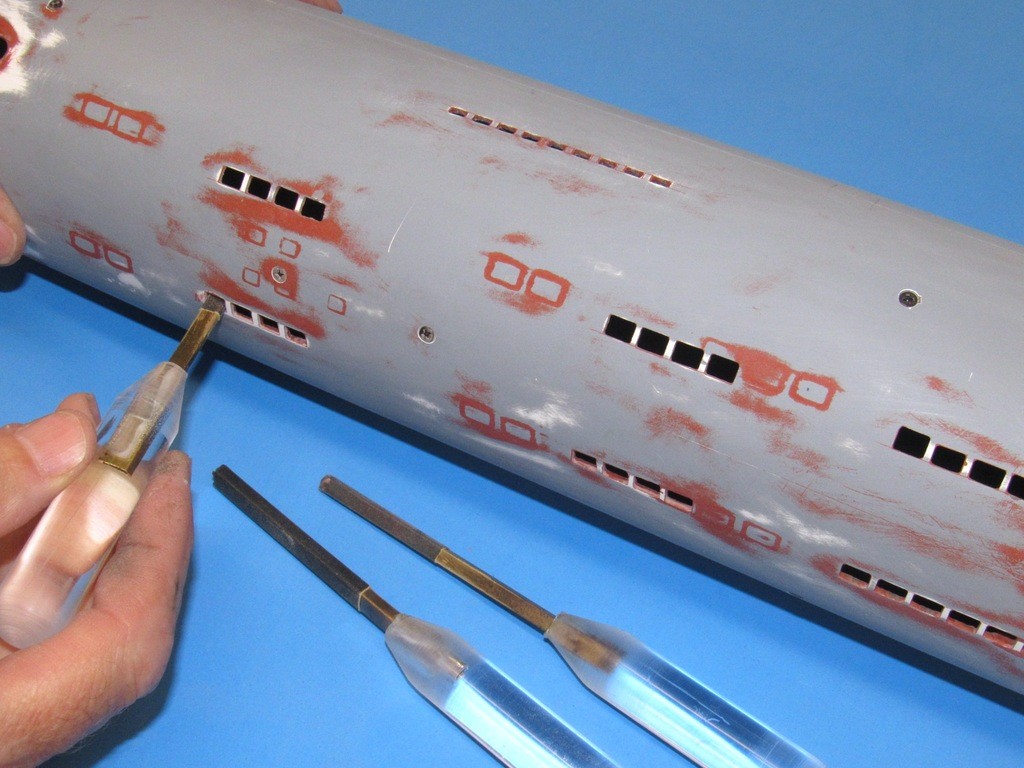

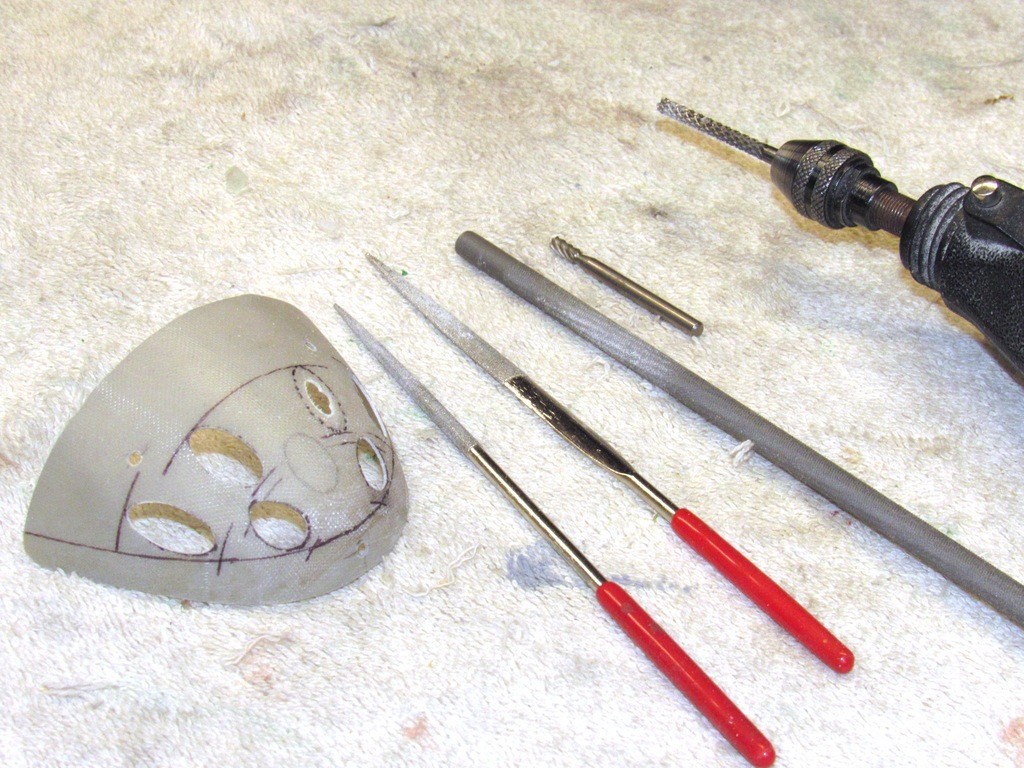

I finally finished all the topside scribing. (Well, almost, I still have to re-establish the port side flat of the after escape trunk hatch). However, I still have to identify the flood-drain holes beneath the hull. Once I’ve denoted the location and shape of those holes I’ll open them up with the aid of rotary burr and hand-files. And the two secondary loop scoops have to be glued to the lower hull and filleted in.

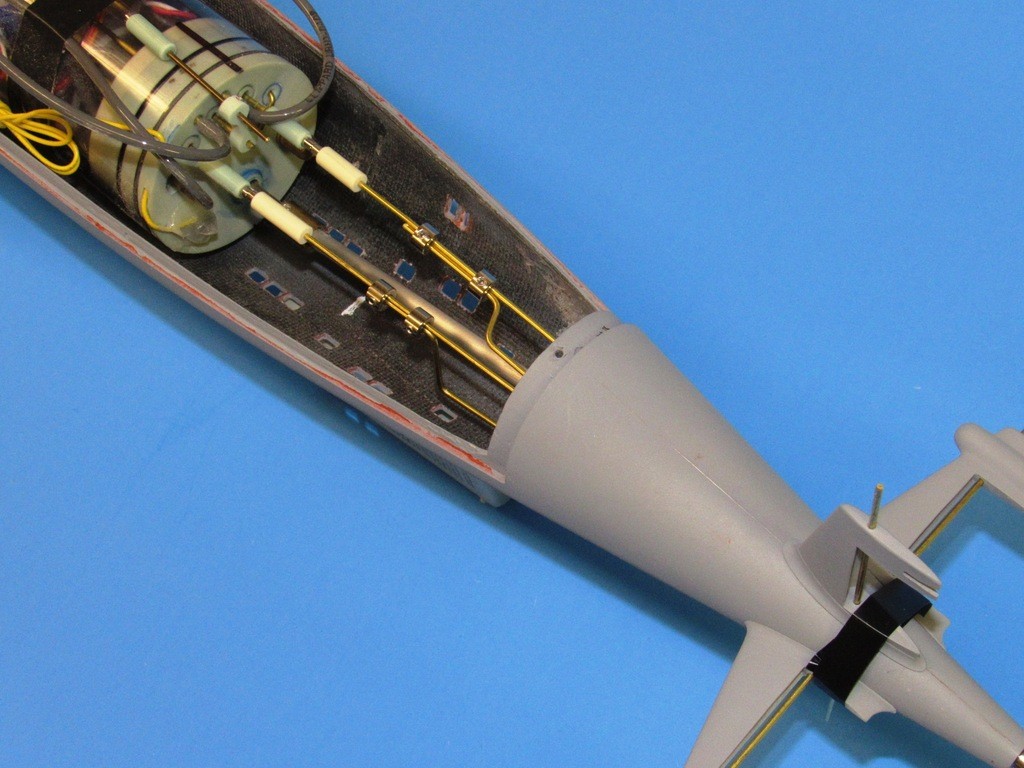

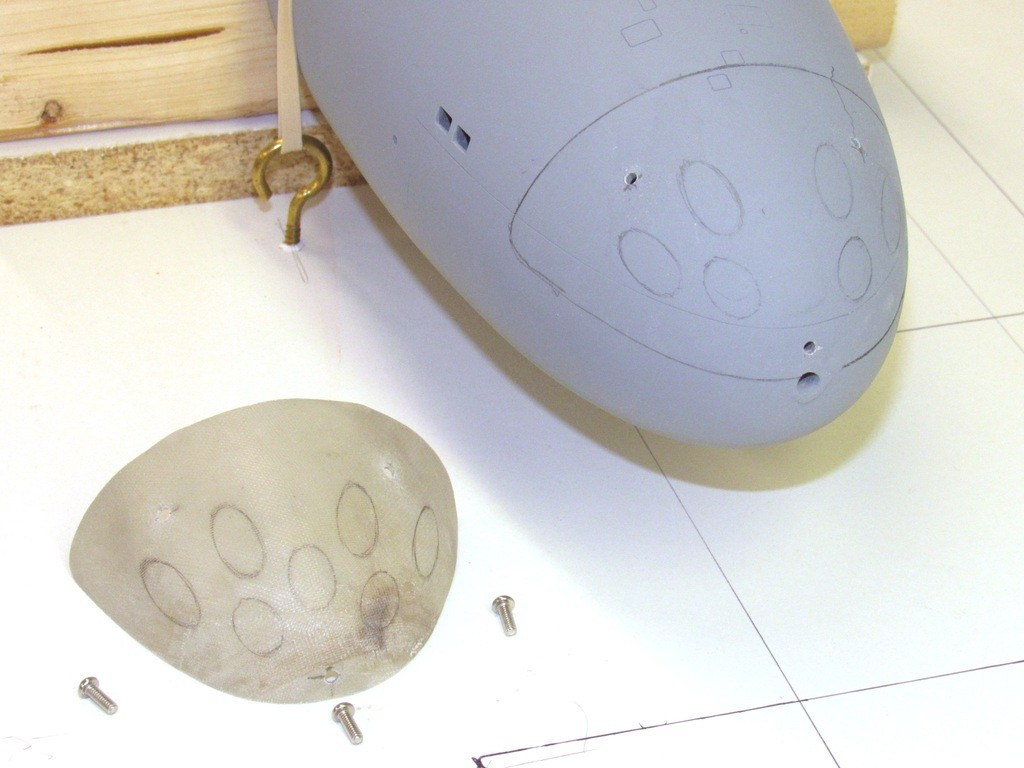

I’ve established the locations of the bow plane operating shafts, and installed a well for the emergency marker buoy. Things are rolling along at a good pace.

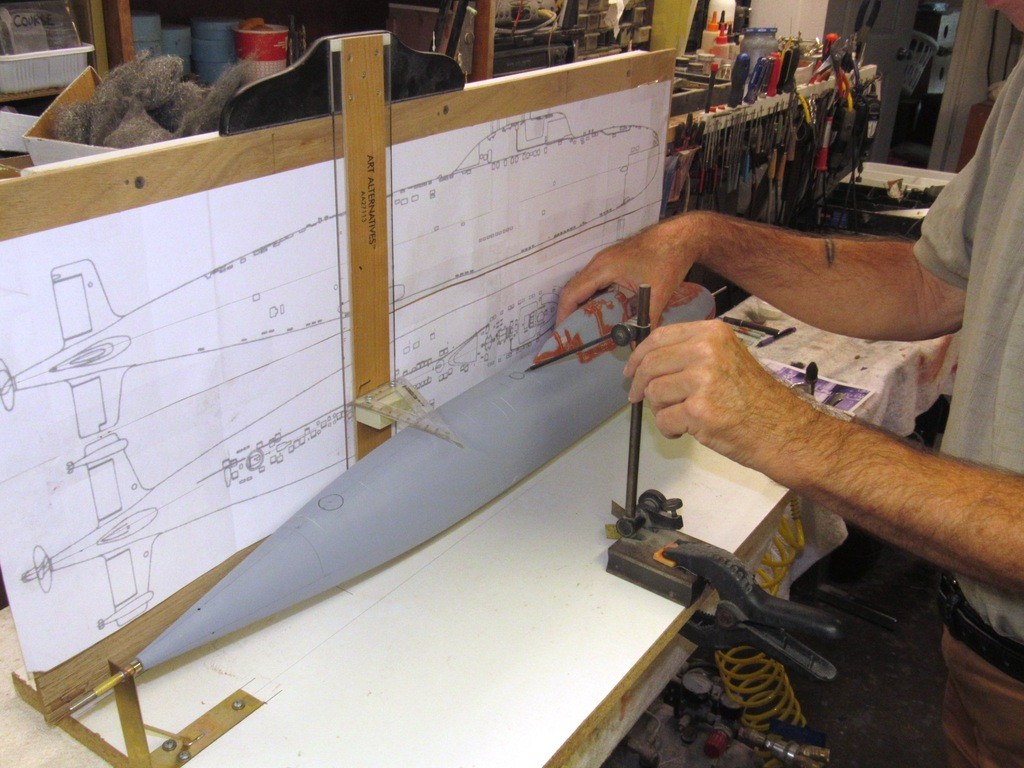

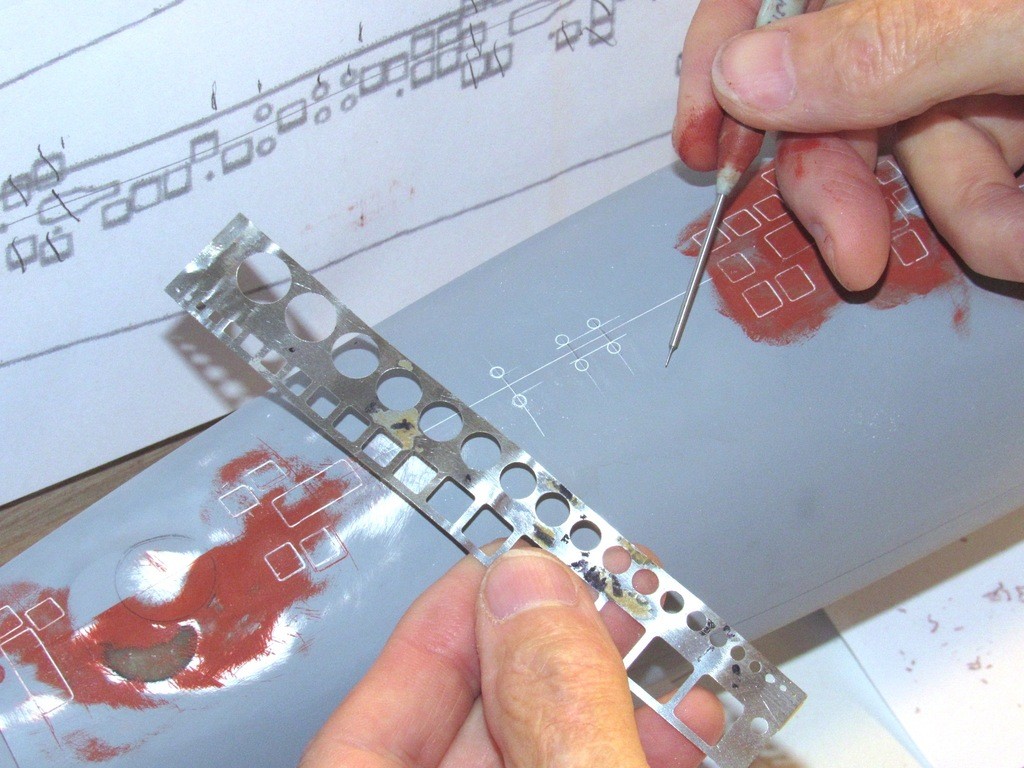

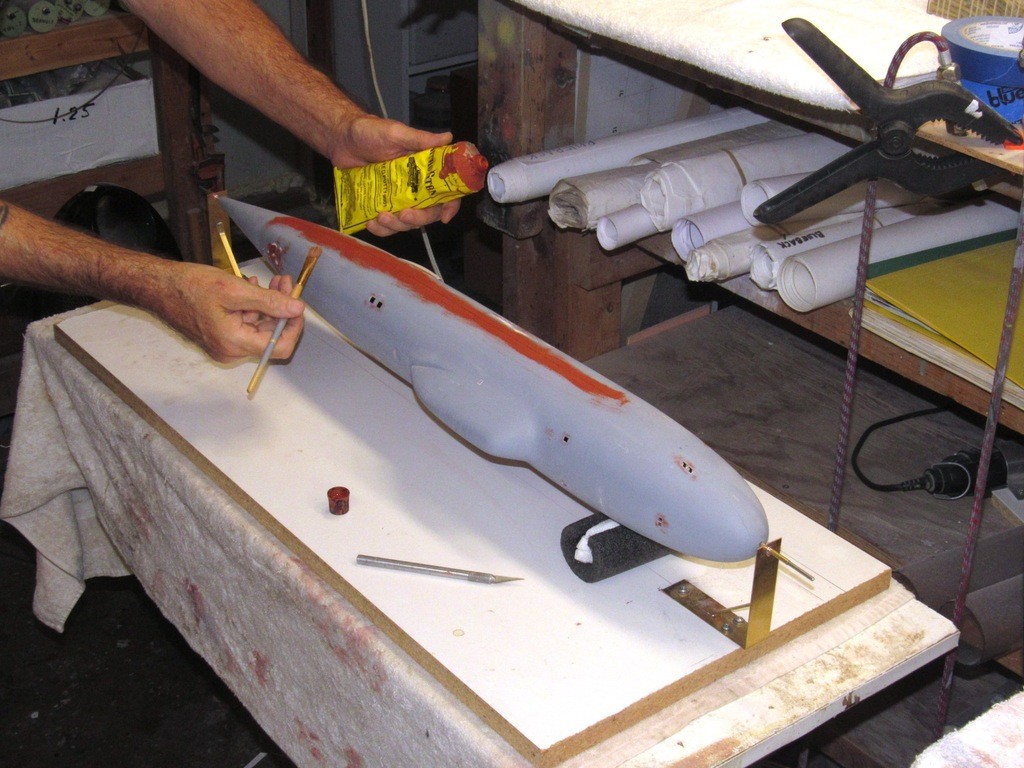

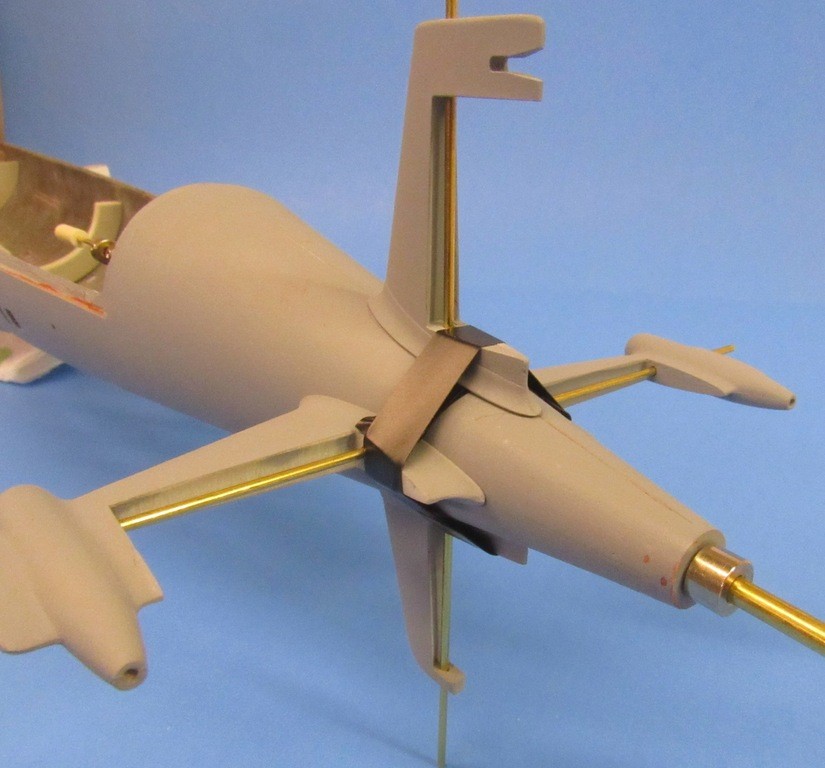

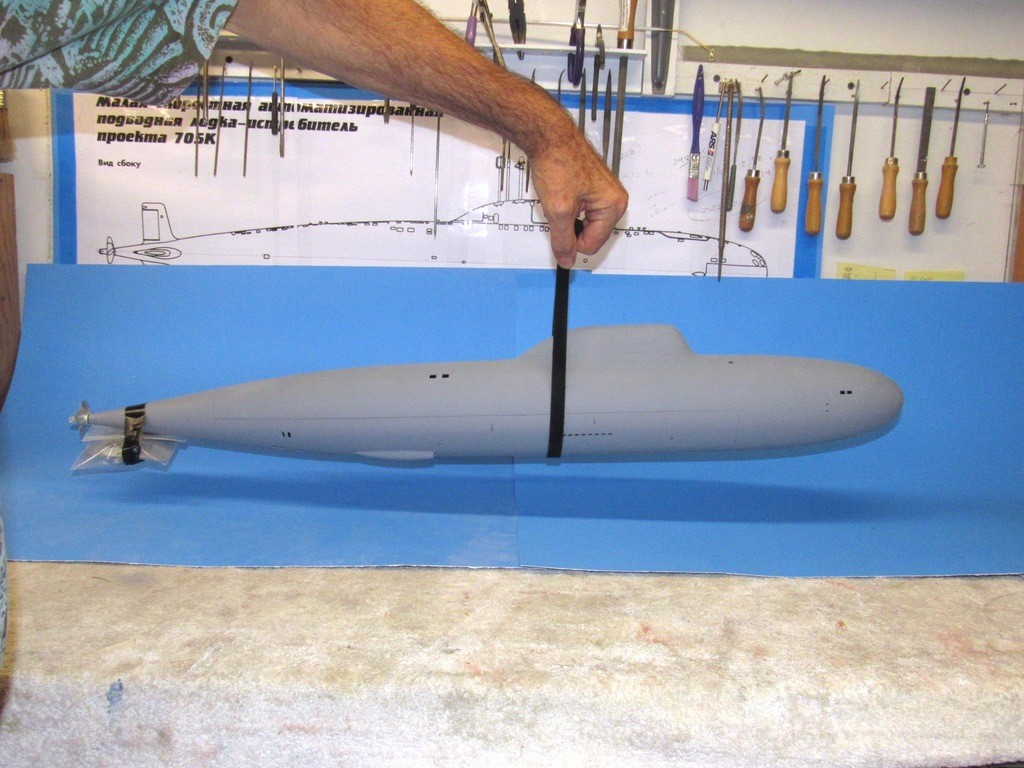

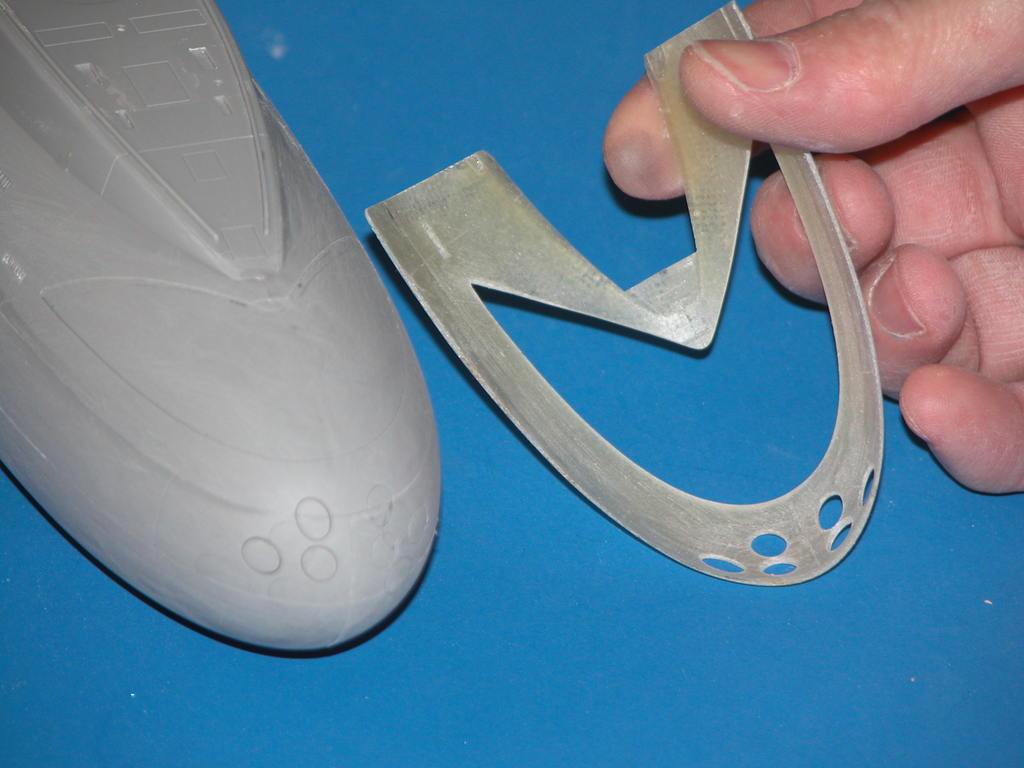

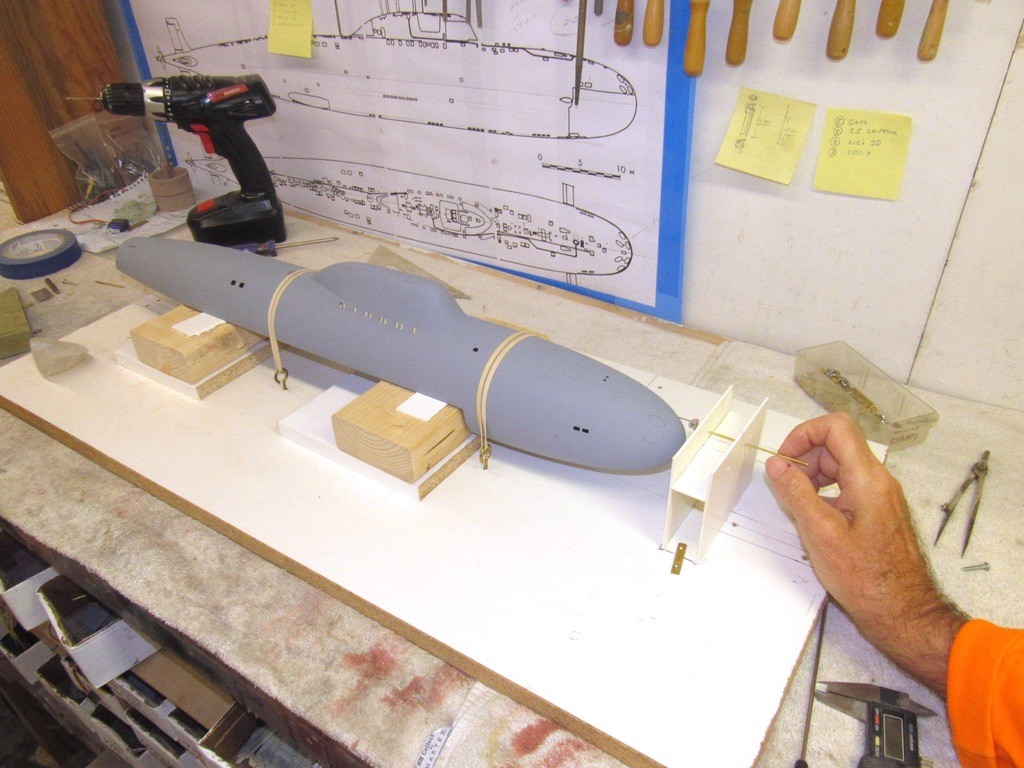

Some old business: I promised to show the modified T-square I use to loft the position of an item on the plan to the physical model with reasonable ease and accuracy. The picture should be self-explanatory.

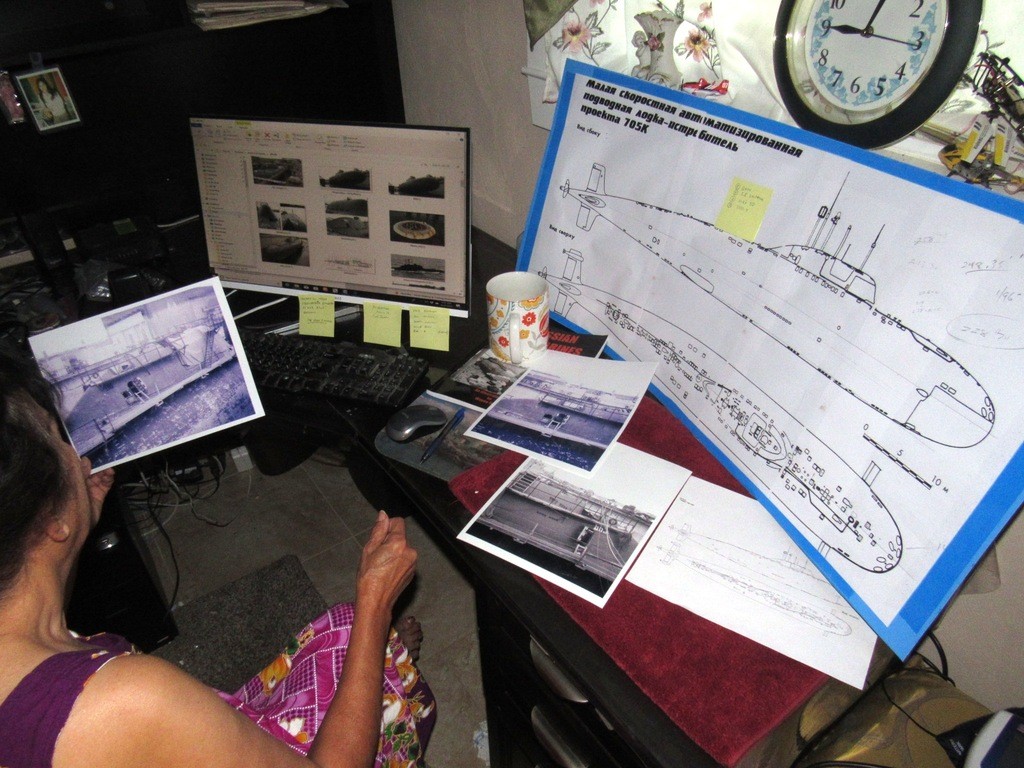

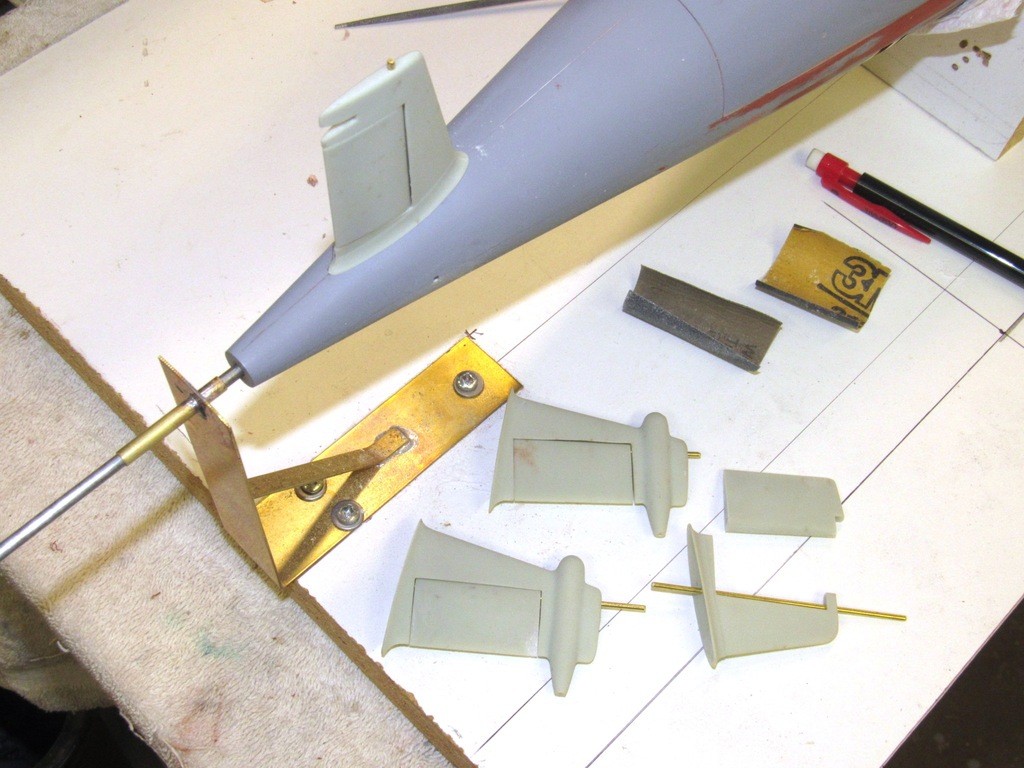

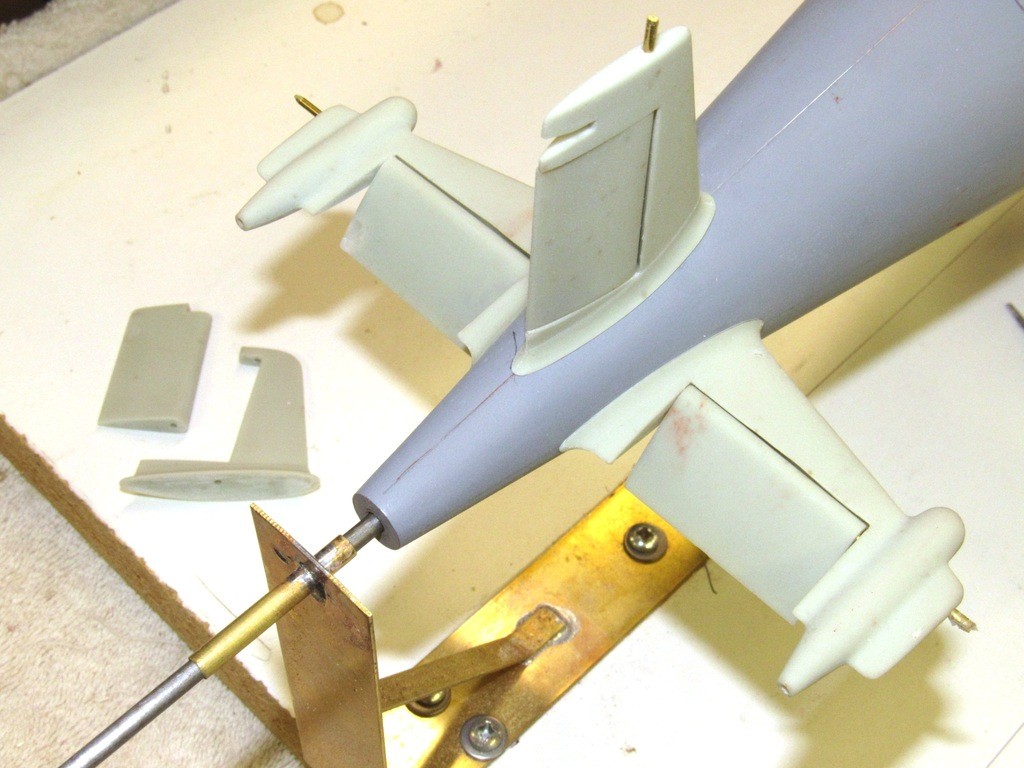

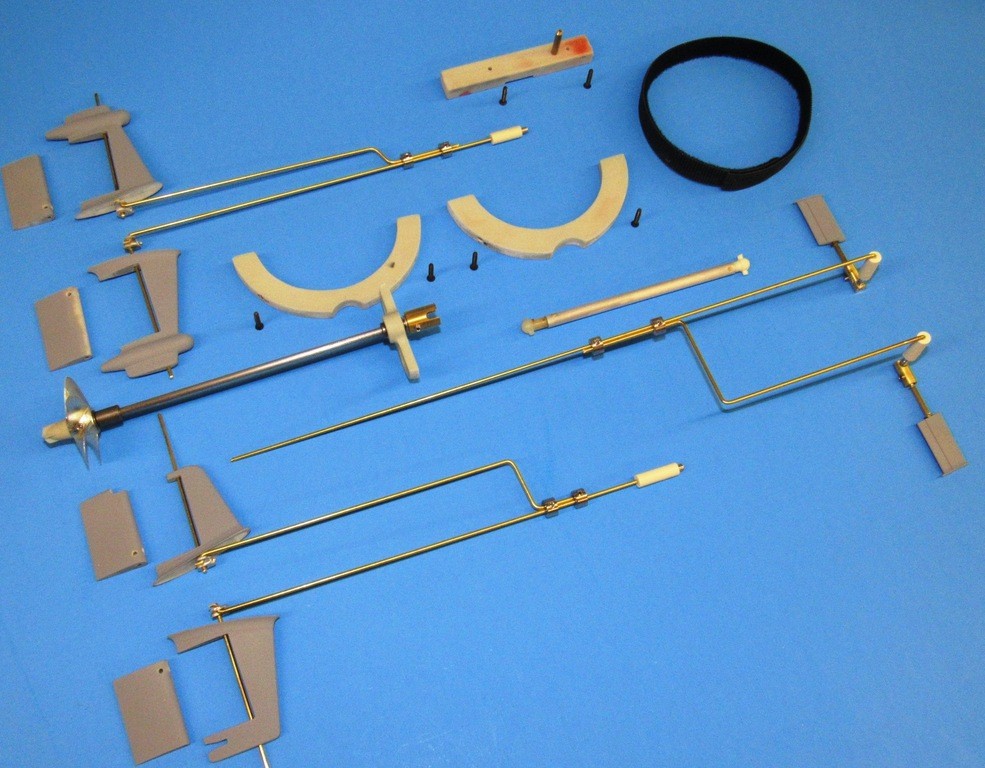

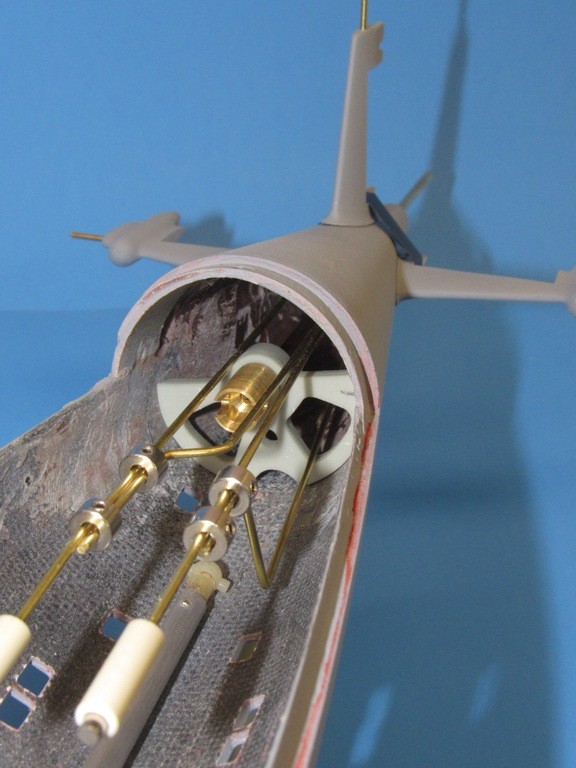

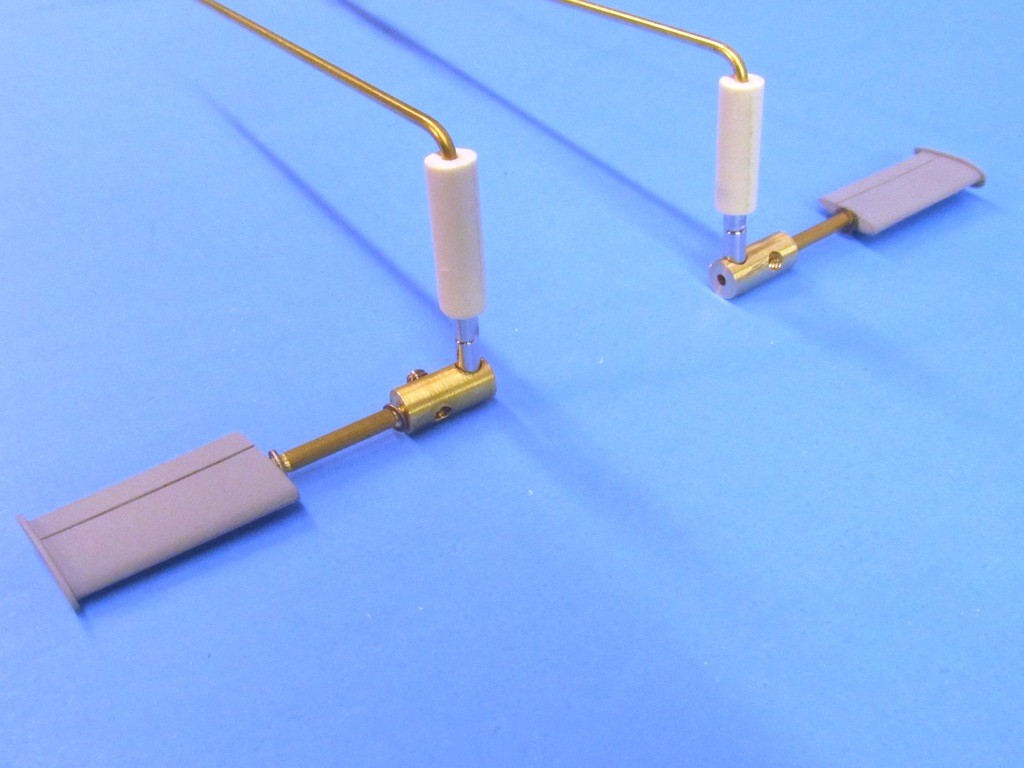

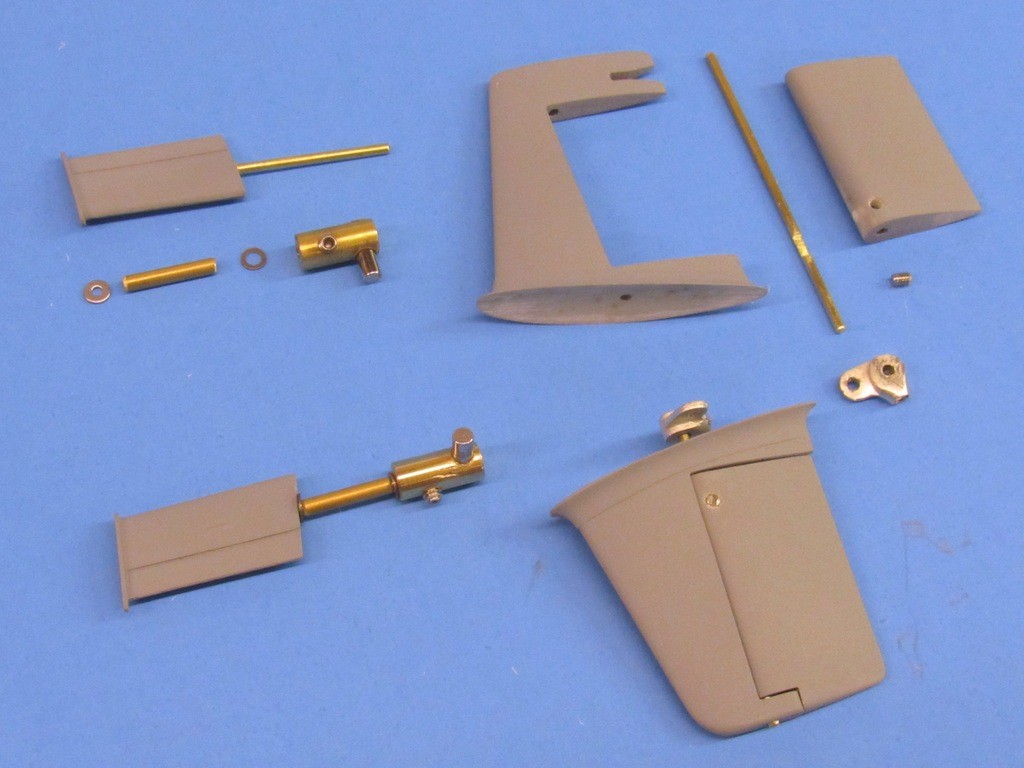

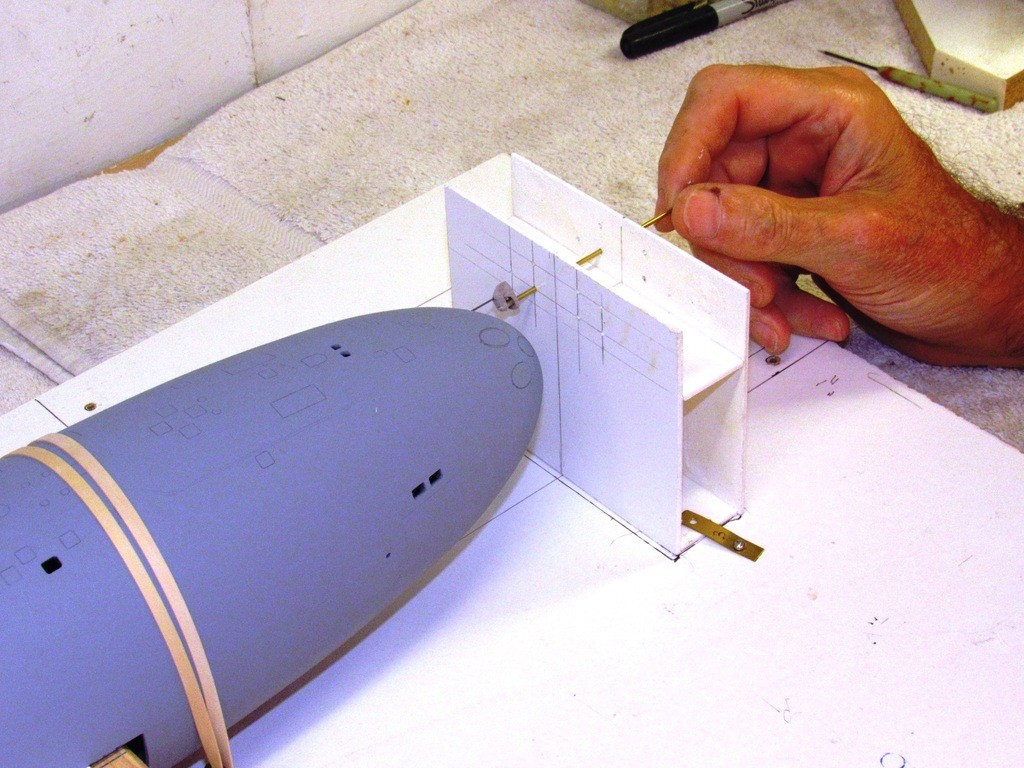

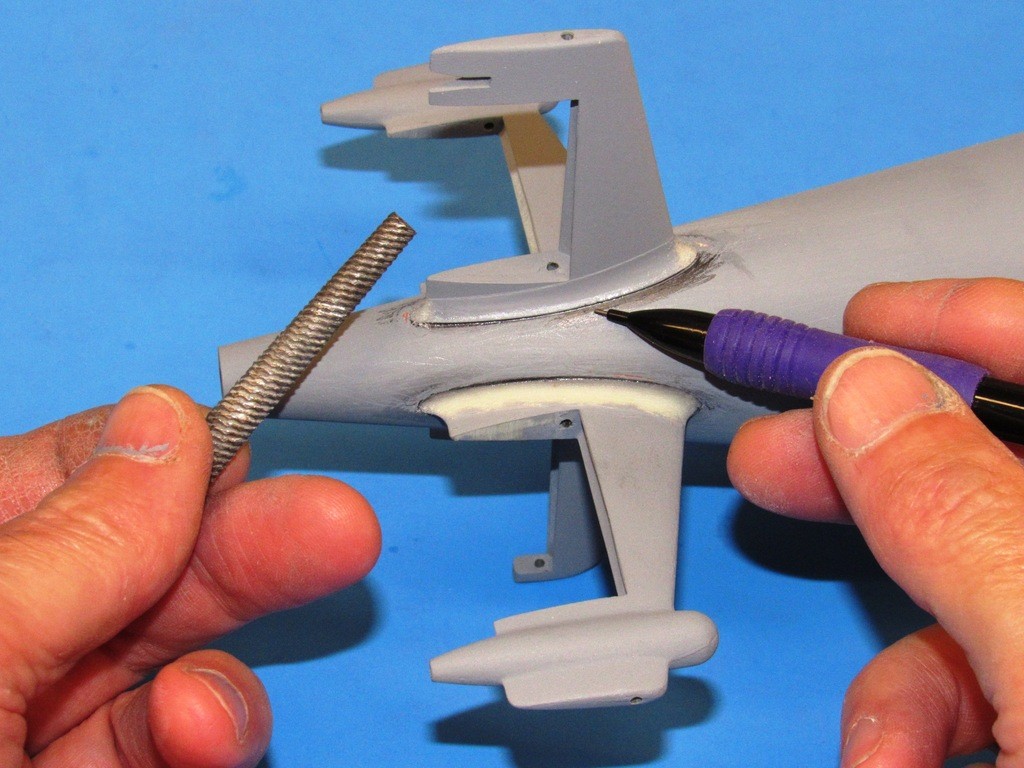

I mocked up the bow plane arrangement. As is my want, I endeavor to make the bow/sail planes on my r/c submarines practical. Such is the case with this little 1/96 ALFA class submarine. A unique feature of this class of submarine was the height stagger between the two planes (to obtain the internal clearance of the retract mechanism when the planes are housed in the ‘retracted’ position). A unique feature, I wanted to show-case; a little chaos is a good thing every now and then.

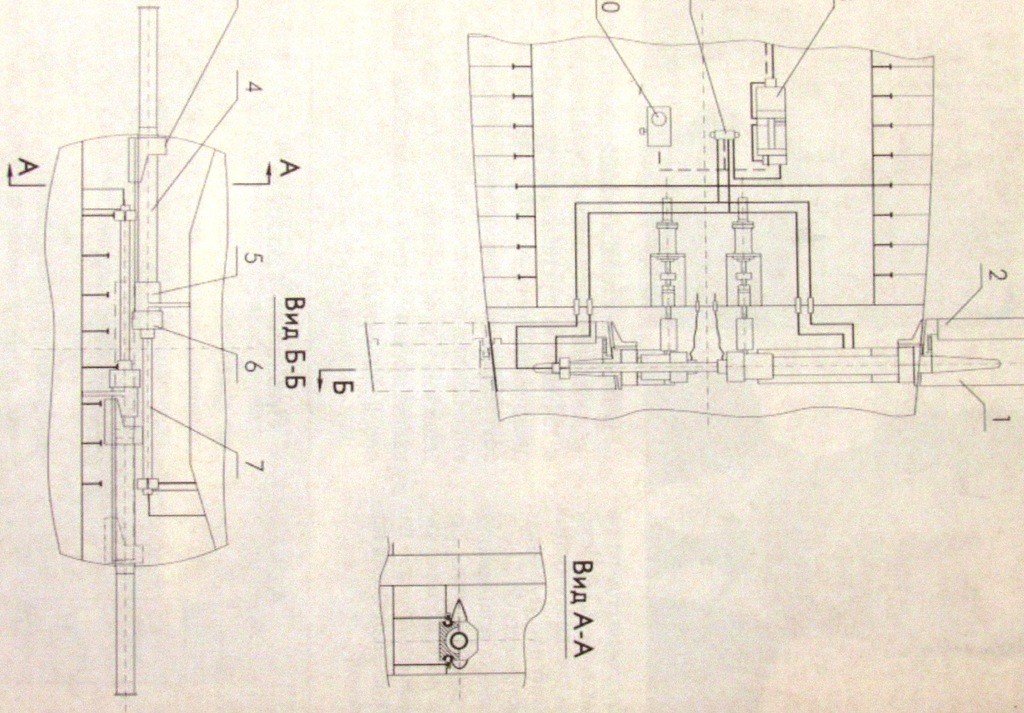

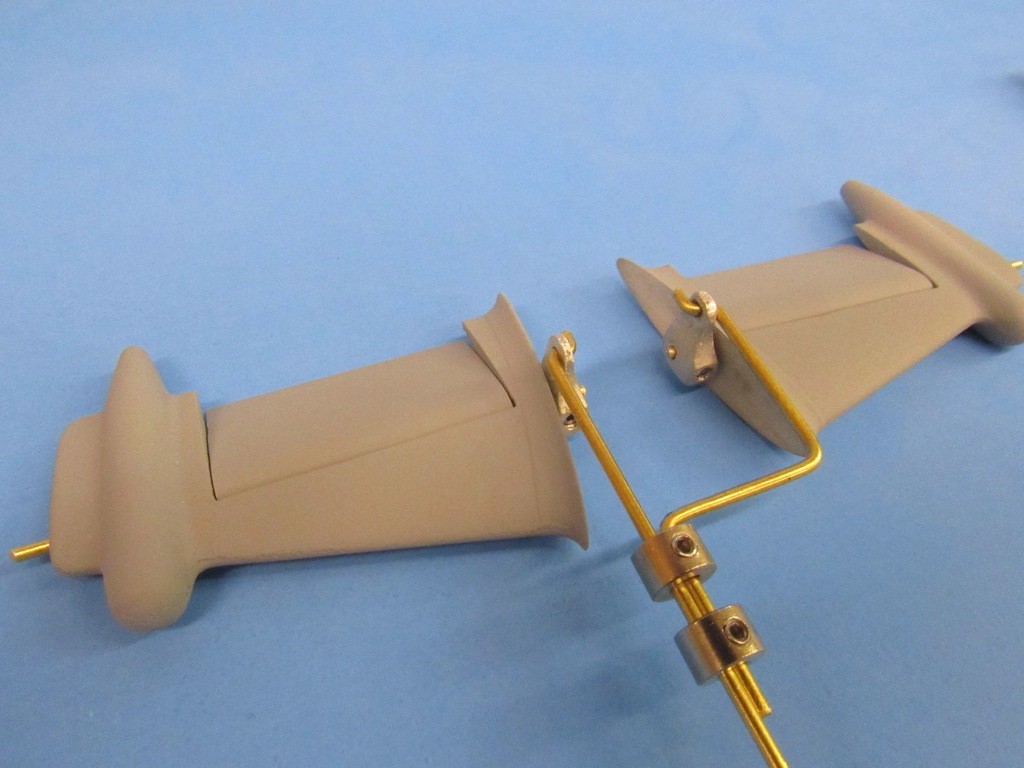

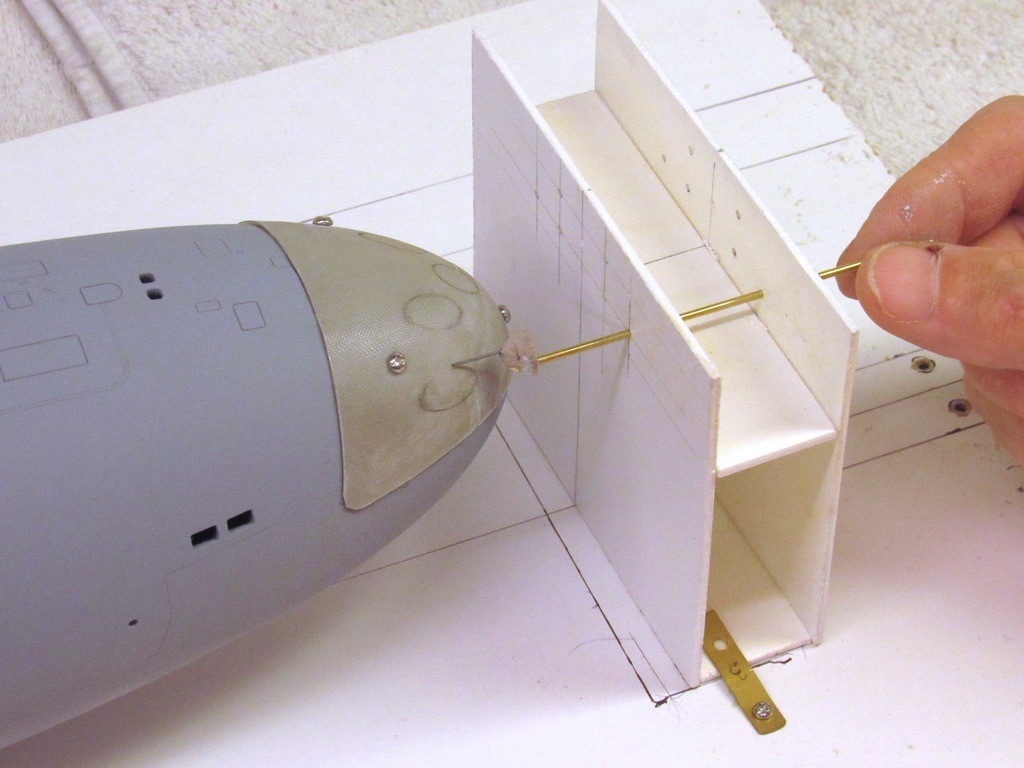

An example of intentional asymmetry on the ALFA design is the vertically displaced distancing of the two bow planes. Note how they are staggered in relation to each other. As these retractable control surfaces slide in and out from the ‘retracted’ and ‘deployed’ positions there was not enough space between them, when retracted, to position them on the same vertical plane. Malachite’s solution was to stagger them (one above the other) to get these long-of-span control surfaces to fully retract when stowed.

I assume that the bow planes were only rigged out when operating at periscope depth or during evasive maneuvers where rapid depth change rates were required. Otherwise, these dragy control surfaces would have been neatly tucked into the hull. After all, the ALFA’s were the Soviet’s second fastest combatant type submarine ever in service, so everything that could be done to make these boats ‘slick’ was done. You don’t need bow planes when you’re booking along on a flank bell at transit depth.

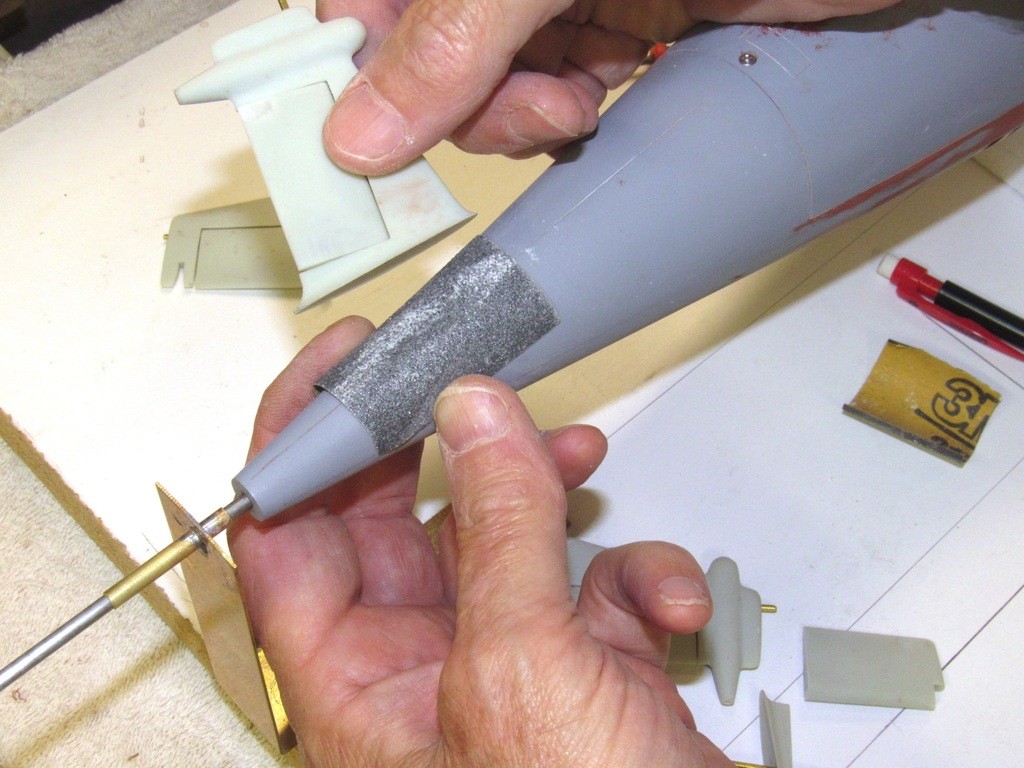

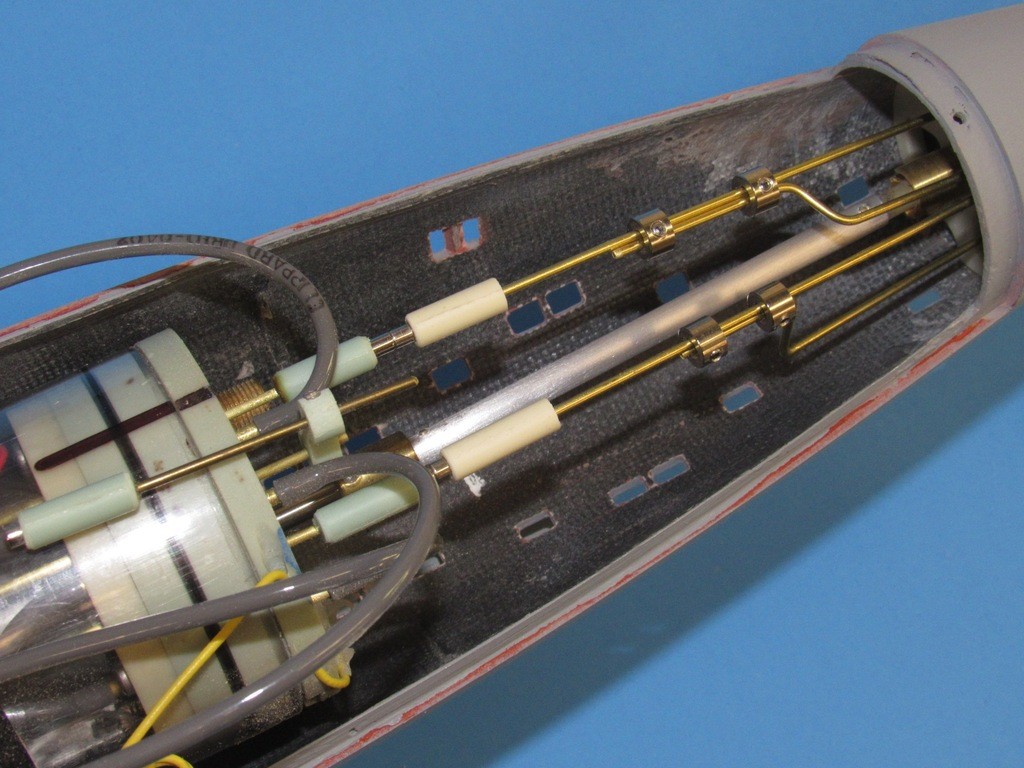

Because the two control surfaces don’t share the same plane, I cannot use a single operating shaft between the two bow planes. I’ll have to provide each with its own bearing tube within the hull and interconnect the two operating shafts (one per plane) with a flexible coupler, likely a short length of flexible rubber tubing – an arrangement that will permit both planes to rotate in unison off of one bell-crank.

To insure that the internal bow plane operating shaft bearing tubes are positioned parallel with one another I’ve extended a temporary operating shaft through the hull with a bit of it projecting through the opposing side of the hull. Later, these extended, temporary operating shafts will jig the bearing tubes in correct position as I epoxy them within the hull.

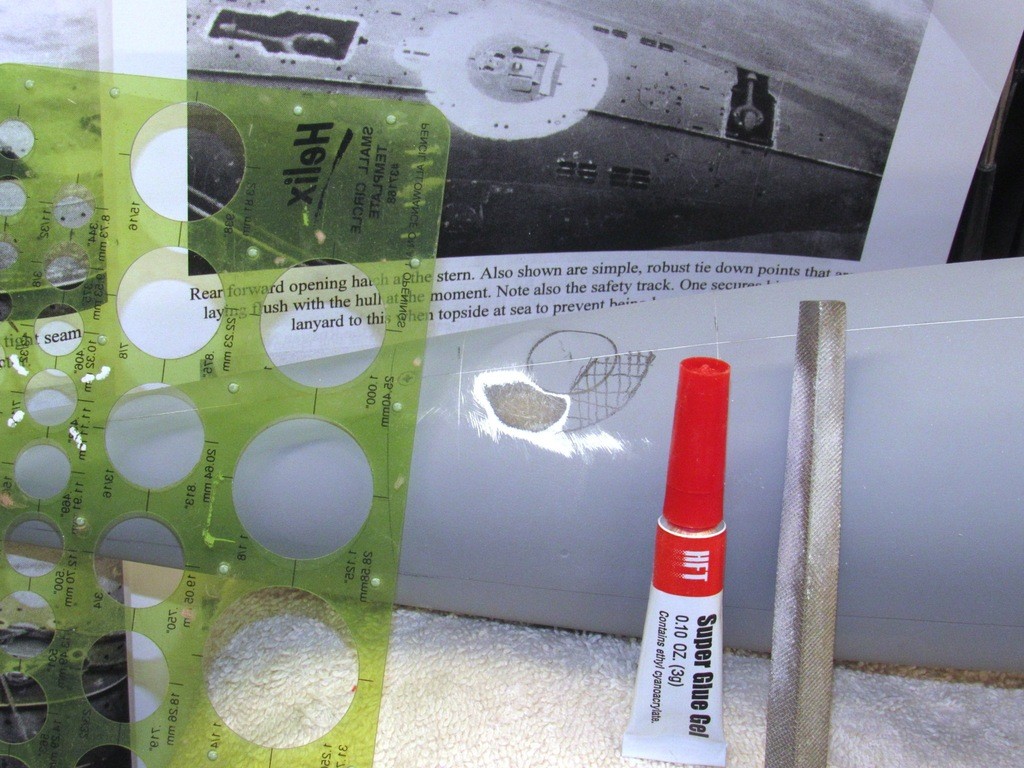

The escape buoy sits in a well. I turned a well from some RenShape and CA’ed it into a hole I punched atop the hull, just aft of the sail.

I could have elected to simply scribe a circle to represent the demarcation between circular buoy and deck, but I’ve been giving some thought of making a practical buoy – as advocated by Manfred Reusing who has been outfitting his scale r/c submarines with such a sub-system for decades -- never hurts to have a back-up to get a disabled, sunken model submarine back to the surface!

A possibility, later, taking Manfred’s lead, is to outfit the model with a practical float that would be tethered to the model through a long fishing-line down-haul cable. The buoy released to rise to the surface once a water-soluble retainer had been exposed to water for a significant amount of time (a piece of spaghetti or a Tic-Tac).

There were only three significant errors I’ve found on the hull: the Sail is too short (but to be honest, this model might be representing the prototype which reportedly had a sail of different contours than the production boats); the torpedo tube shutter doors are to low and too large of diameter; and the location of the after escape trunk hatch flat is too far aft.

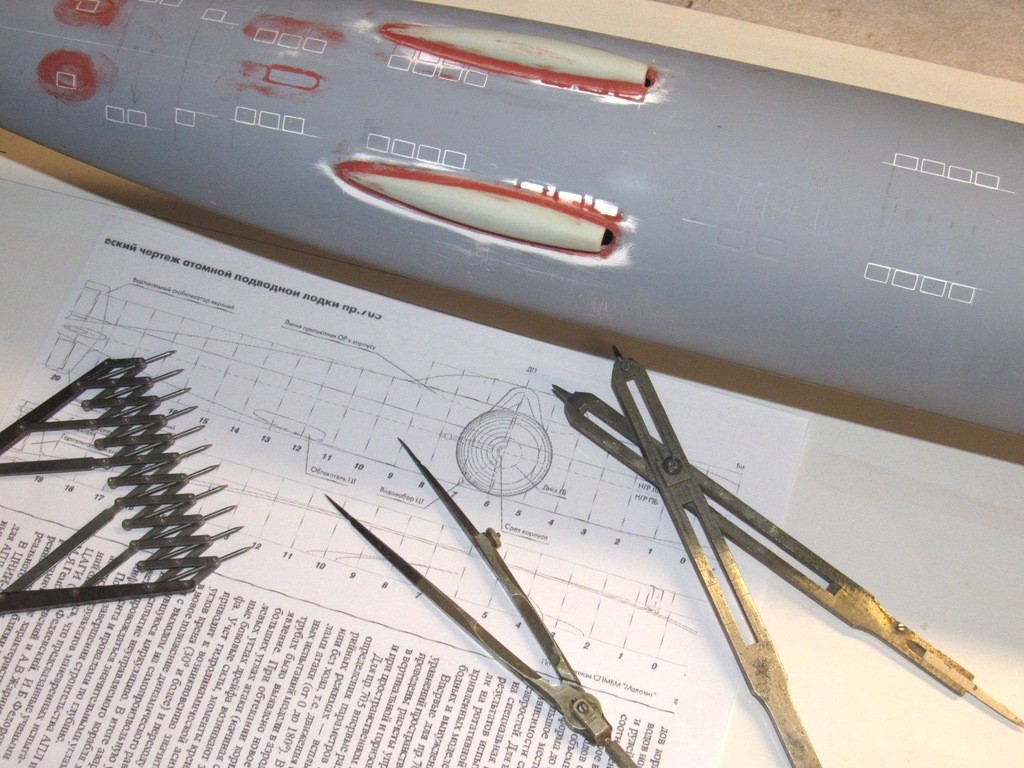

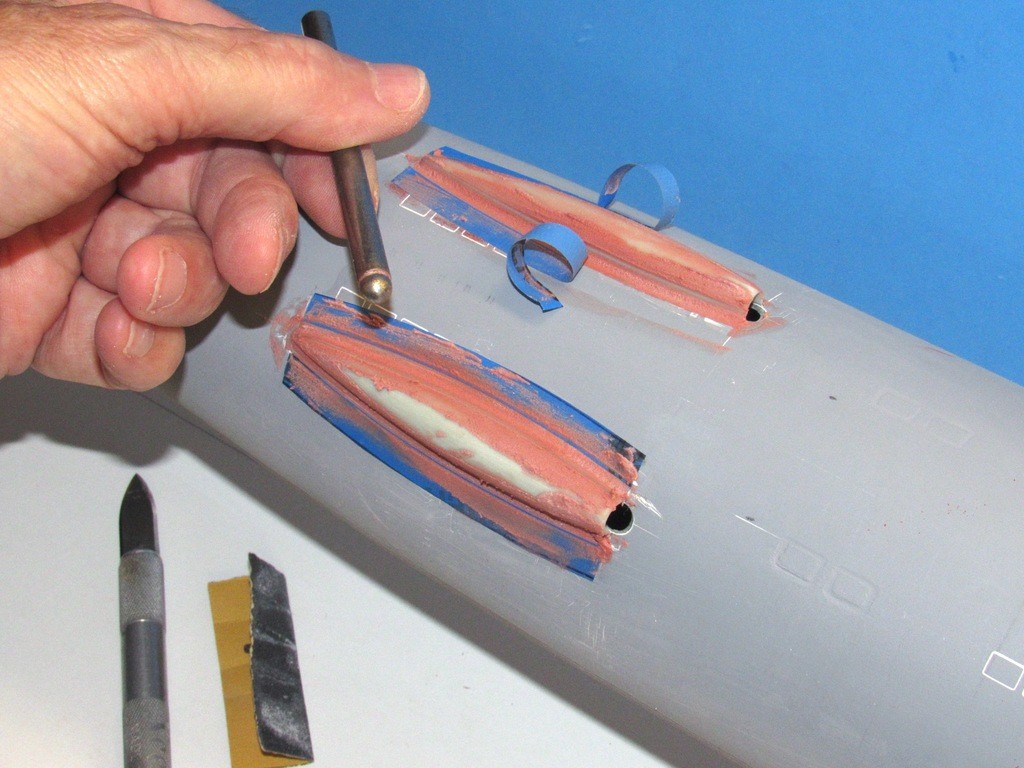

Here I’ve – for the sake of illustration – only worked one-half of the after escape trunk hatch flat. First I used a course file to shave down the after flat (the bare GRP exposed) to the normal contour of the hull, and used CA and baking soda to build up a mass forward (where the penciled hash-marks is) that is then filed to a new flat. The port side eventually got the same treatment.

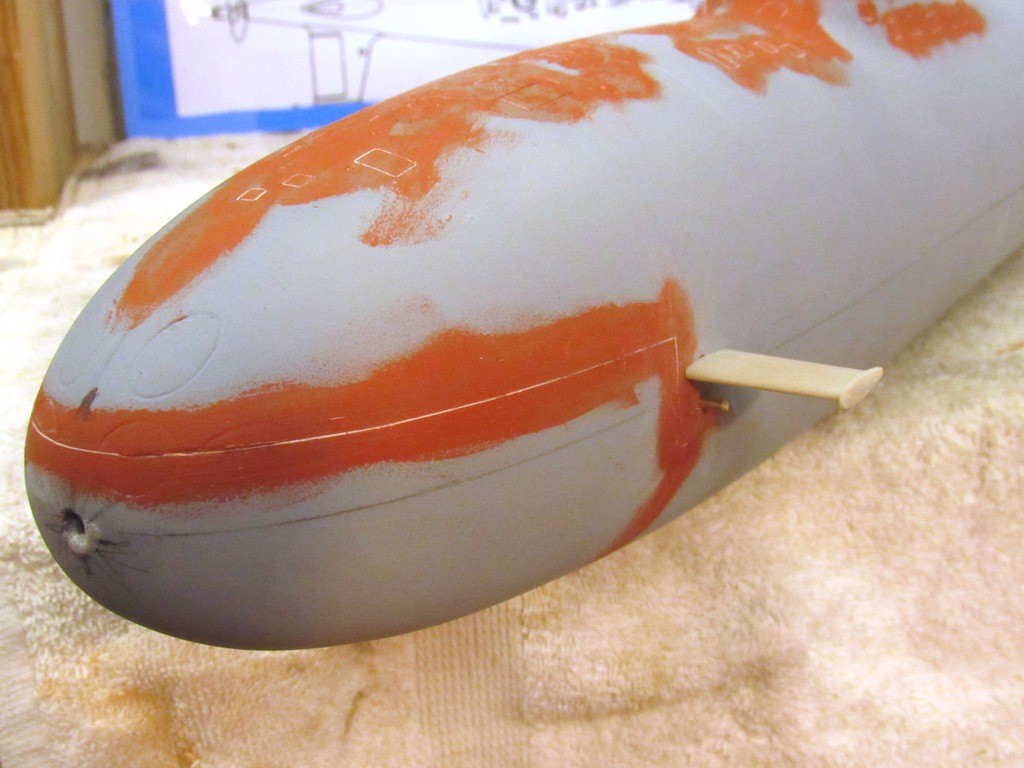

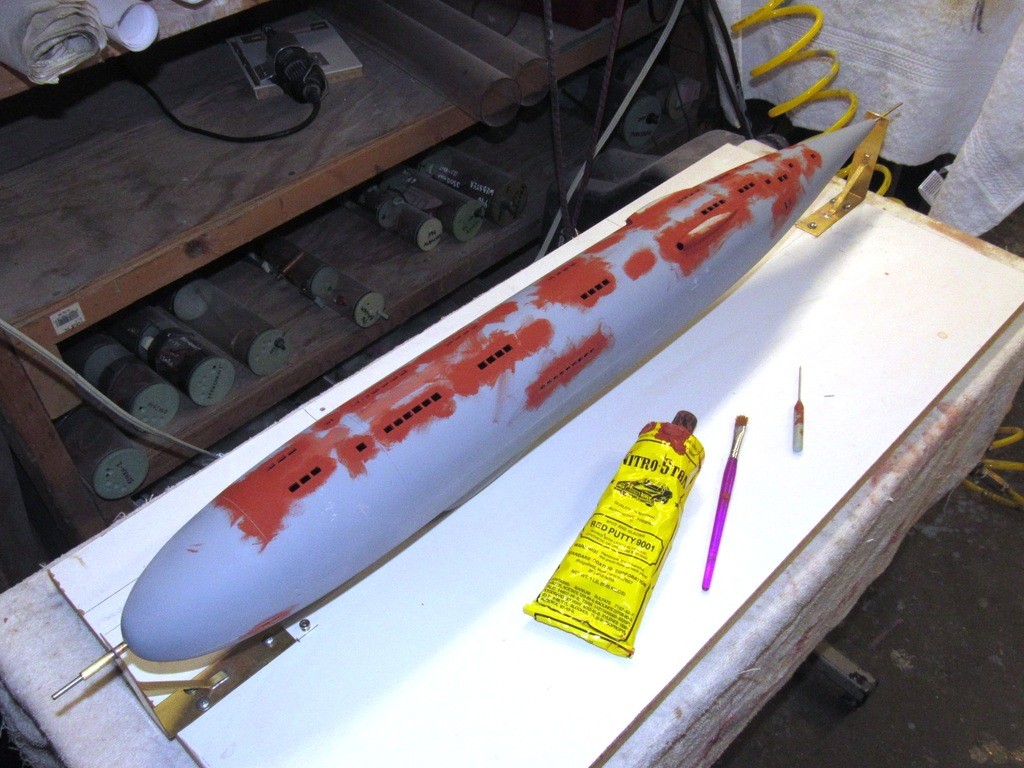

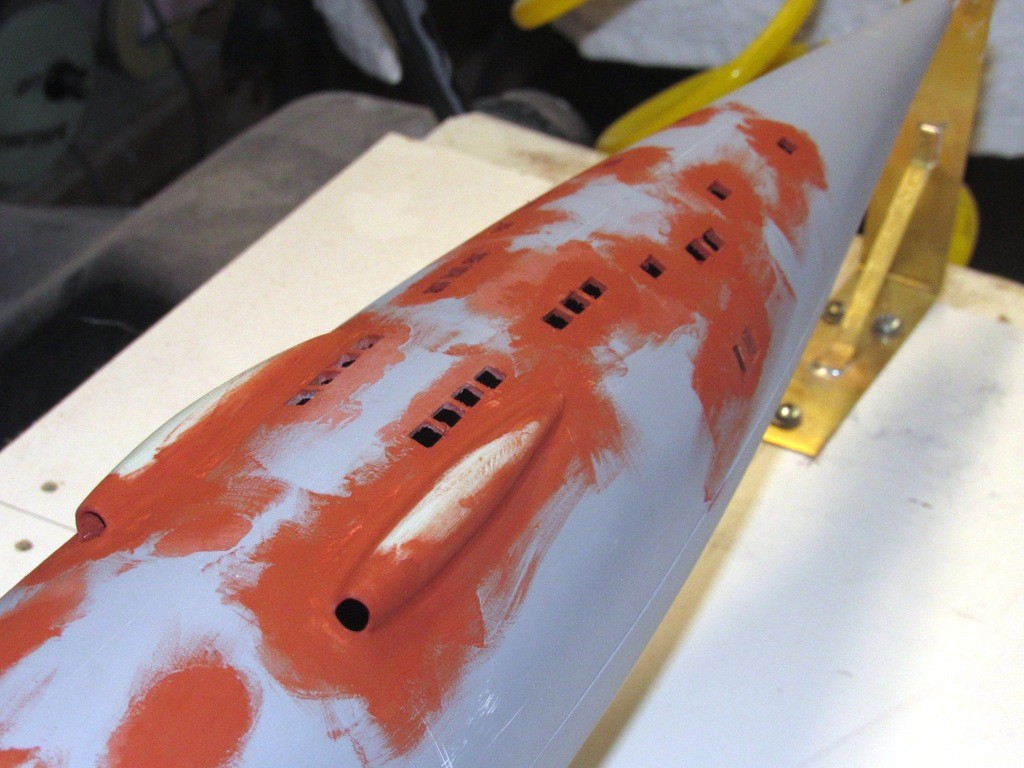

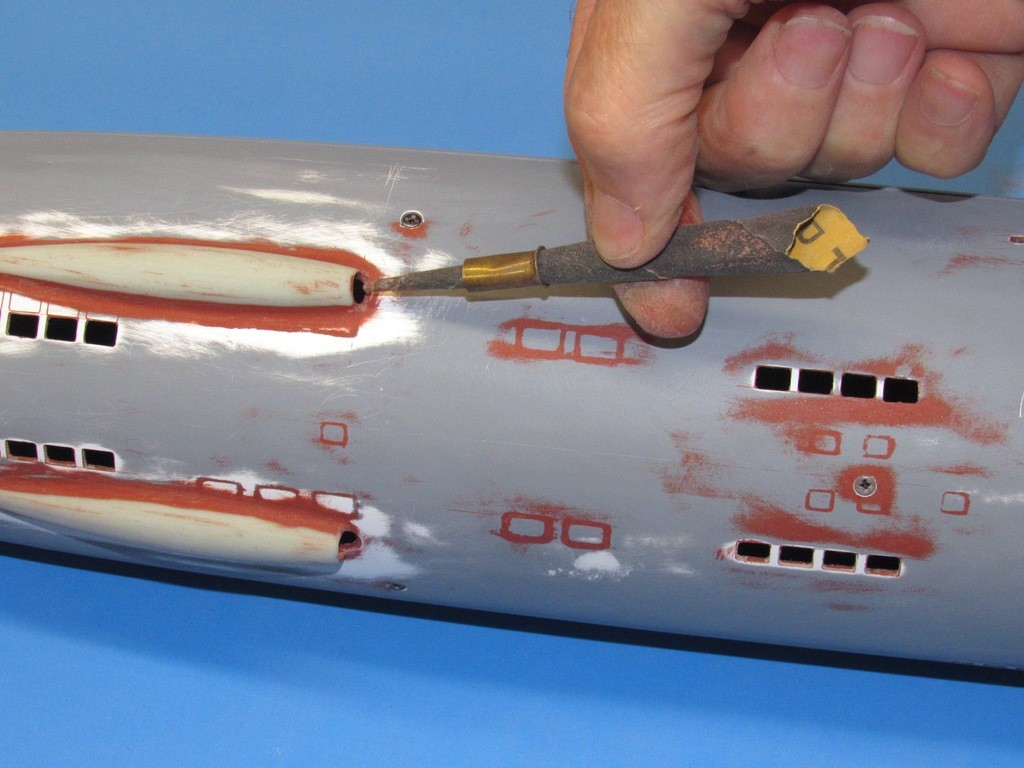

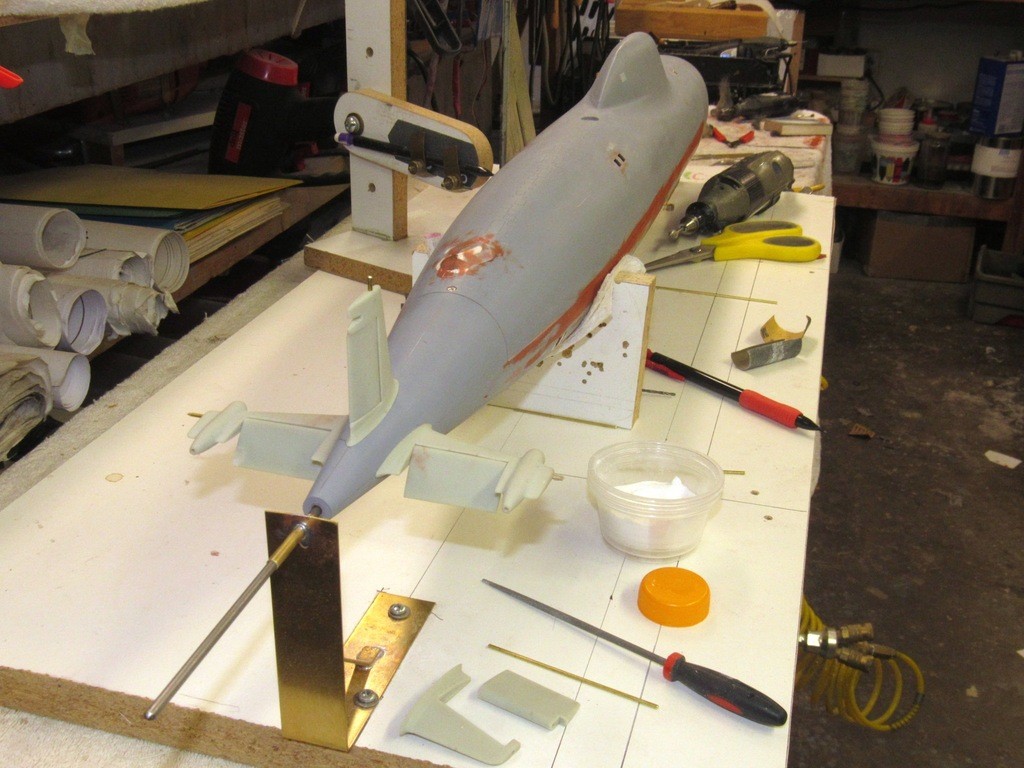

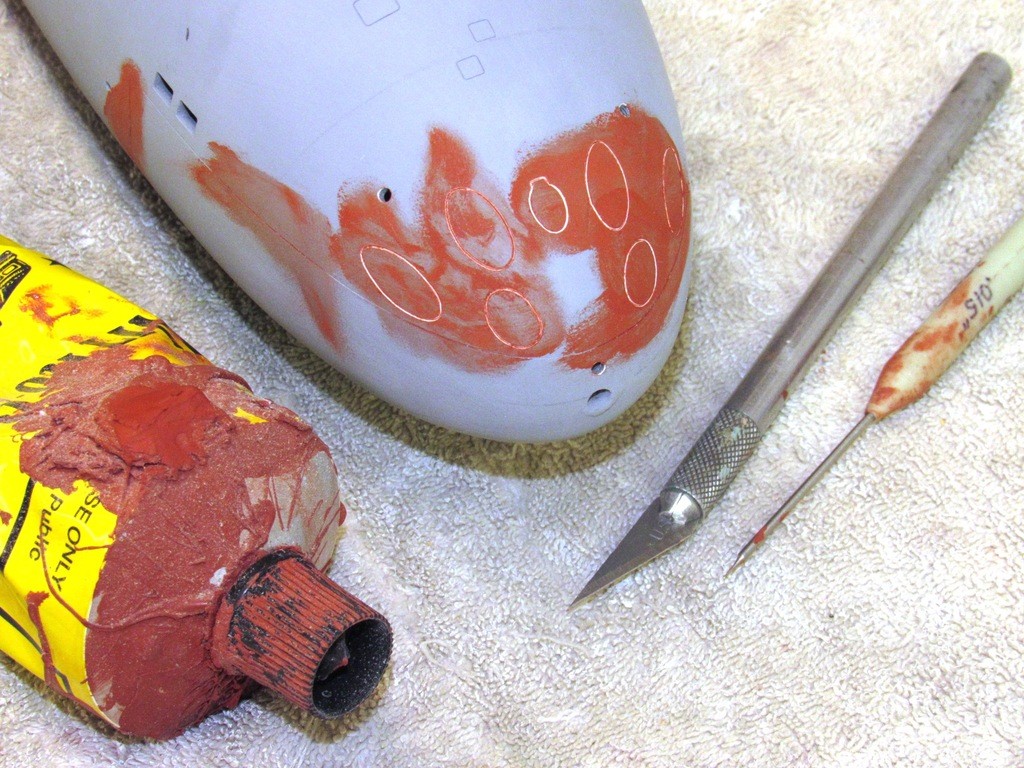

After scribing in the deck and sail details I applied touch-up putty to fill datum lines, cheat-lines, and flawed engraving work. The putty was pushed into the work with a finger, after which I quickly chased out the still wet putty from the engraved items I wanted to retain with the finishing scribe.

The thinly applied putty dries quickly, and those areas were wet-sanded with #600 backed by a semi-stiff sanding block. You can make how the red colored filler fills the flaws.

I’ve already laid down primer to the port side, and you can just make out some of the engraved items. The starboard side is about to get its coat of primer.

Unaddressed flaws, missed or inadequately filled by the putty, are revealed by the gray primer. Such problem areas were addressed with further scribing and/or putty to put the work right, followed by a touch-up blast of primer. This process repeated till things are near perfect.

» Futaba -868/915mhz equipment

» Darnell type 21 submarine, need some help

» Robbe Seawolf V2

» bladder bags

» WW2 mini sub build

» Peral Submarine of 1888

» U-Boat R/C?

» Cheap Arduino Auto leveler