Hermann Wed Jul 06, 2011 7:20 pm

Hermann Wed Jul 06, 2011 7:20 pm

Hello David,

yes, the 7 dark circles you can see on the disc rotor are magnets indeed. They are very common ferrite magnets normally intended to hold/ stick sheets of paper at metal blackboards at the wall. These magnets have a special direction of polarisation, they are polarised in direction of the diameter so the half circle beneath the "aequator" is a south pole, the half circle above is a north pole. So the rotor (and the moulded stator also) has 14 poles. I took ferrite magnets because they had been easy to purchase (in 1993 when I built the first motor, rare earth magnets were hardly available for me). The energy density is much less compared to rare earth magnets but they are full resistant to corrosion in water.

It's not a magnetic coupling between two magnetic rotors (one inside, the other outside the pressure hull) but a real brushless DC motor where the inner rotor is replaced by a stator system equipped with coils and driven by switching transistors. That stator system (that narrow light grey ring) is attached to the aluminium motor housing and moulded with epoxy glued. The control electronics is located inside the cylindrical motor housing that is screwed to the rear wall of the pressure hull with its flange.

The motor has 4 terminals: 2 for power spply from the battery and 2 (signal and return) for connection to the radio control receiver.

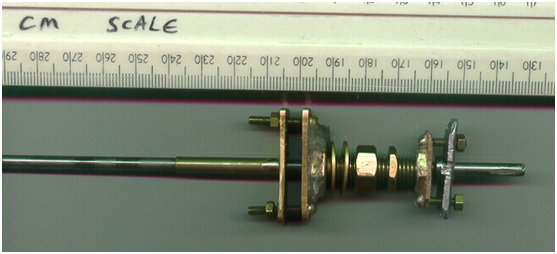

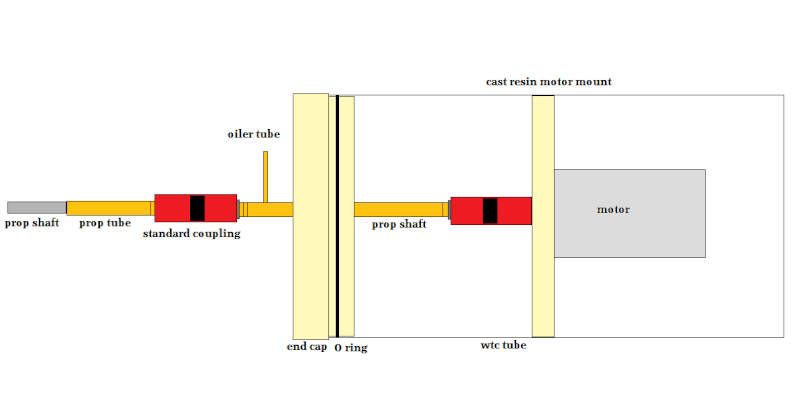

And you can see - there is no seal for the 5mm propeller shaft. The whole rear section of the model is free flooded.

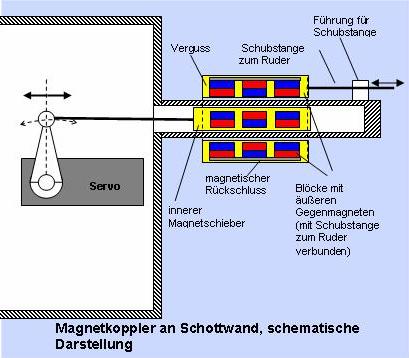

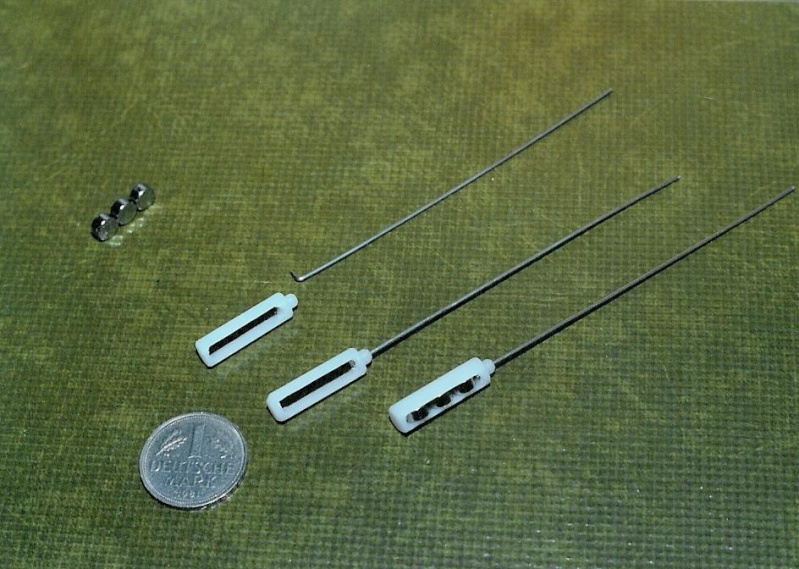

On the photograph you can also see the rods for moving the rudder blades. They are actuated by linear magnetic couplers, also eliminating sliding seals.

I must confess that this is an exotic practice and a some modellers here called me mad for doing this, but why not doing things in an unusual way? That hermetical concept was just an idea and I wanted to prove that it works.

Kind regards

Hermann

Last edited by Hermann on Wed Jul 06, 2011 7:23 pm; edited 1 time in total (Reason for editing : correction of a writing mistake)

» Modulated electric fields for submarine communication in a "heads up" from Harry!

» 868/915 Mhz as a viable frequency for submarines.

» Laser cut Robbe U47 conversion

» ExpressLRS - 868/915 Mhz equipment

» Information on camouflage patterns for German seahund

» WW2 mini sub build

» Not the hobby I expected :)

» Sheerline gasket material