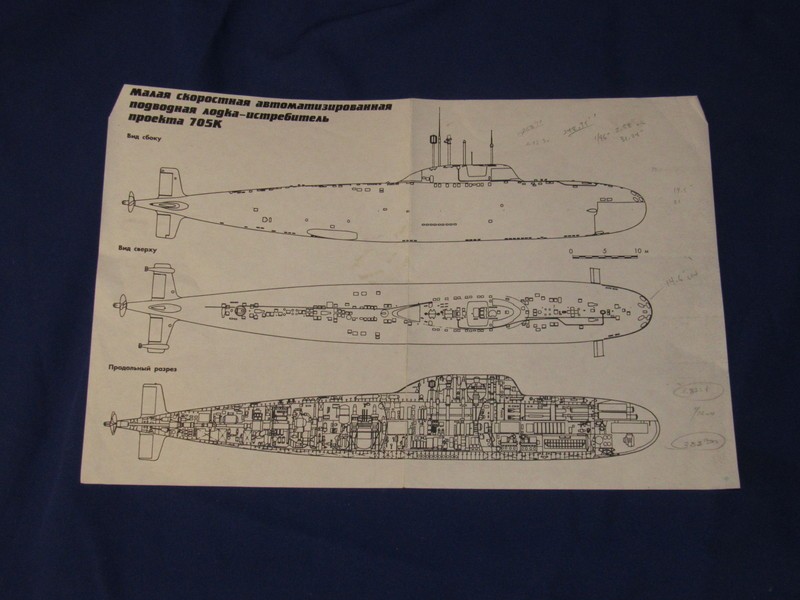

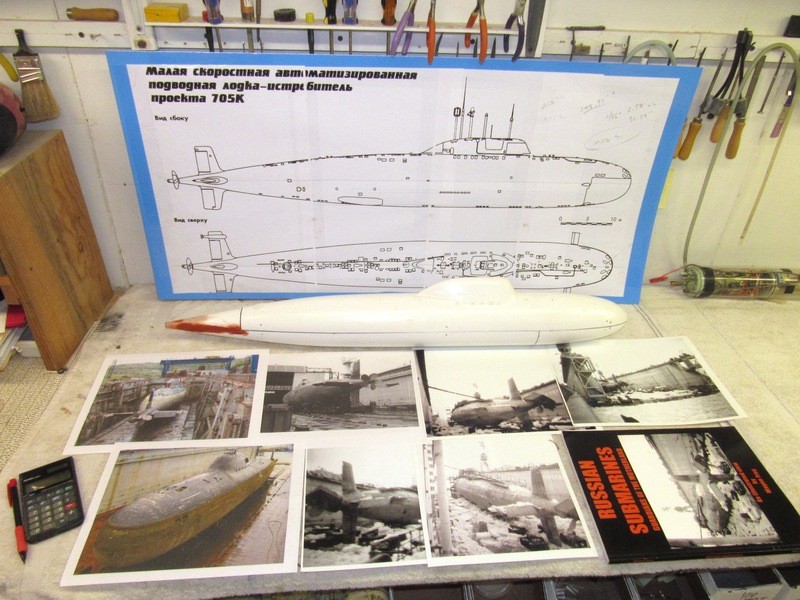

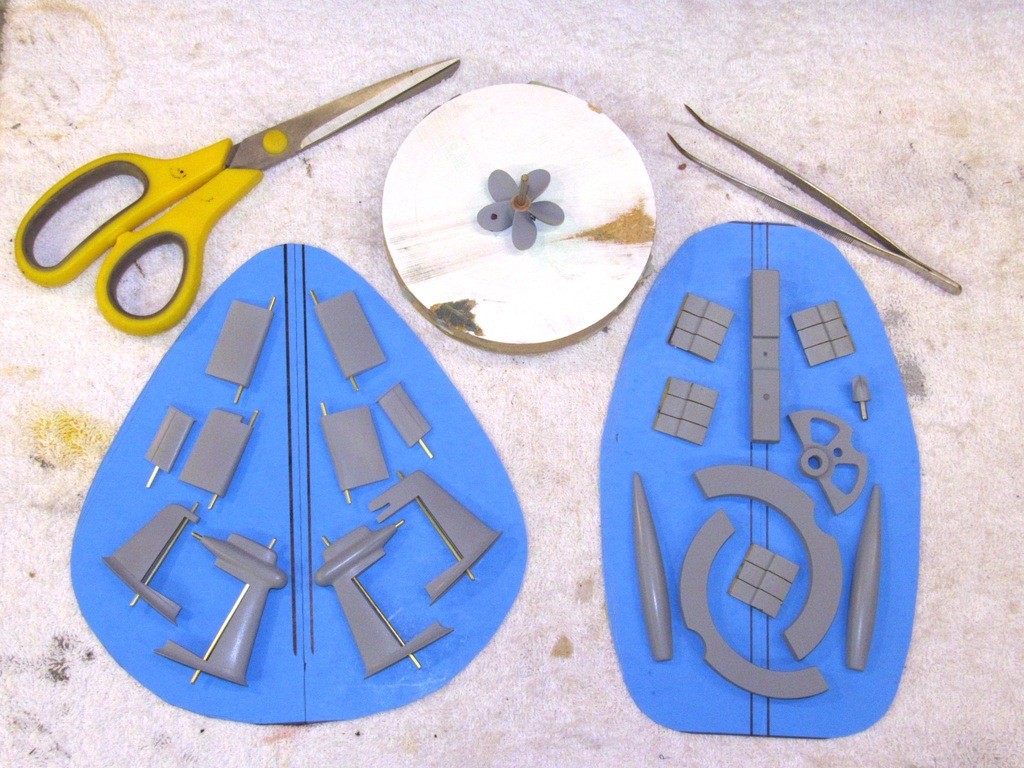

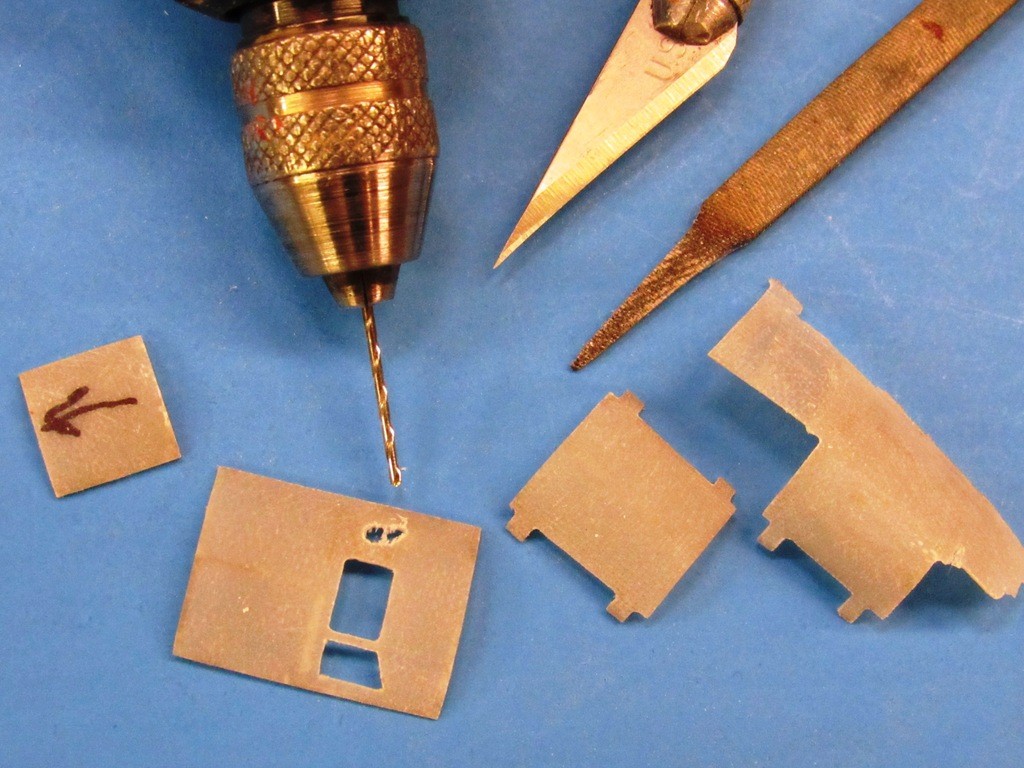

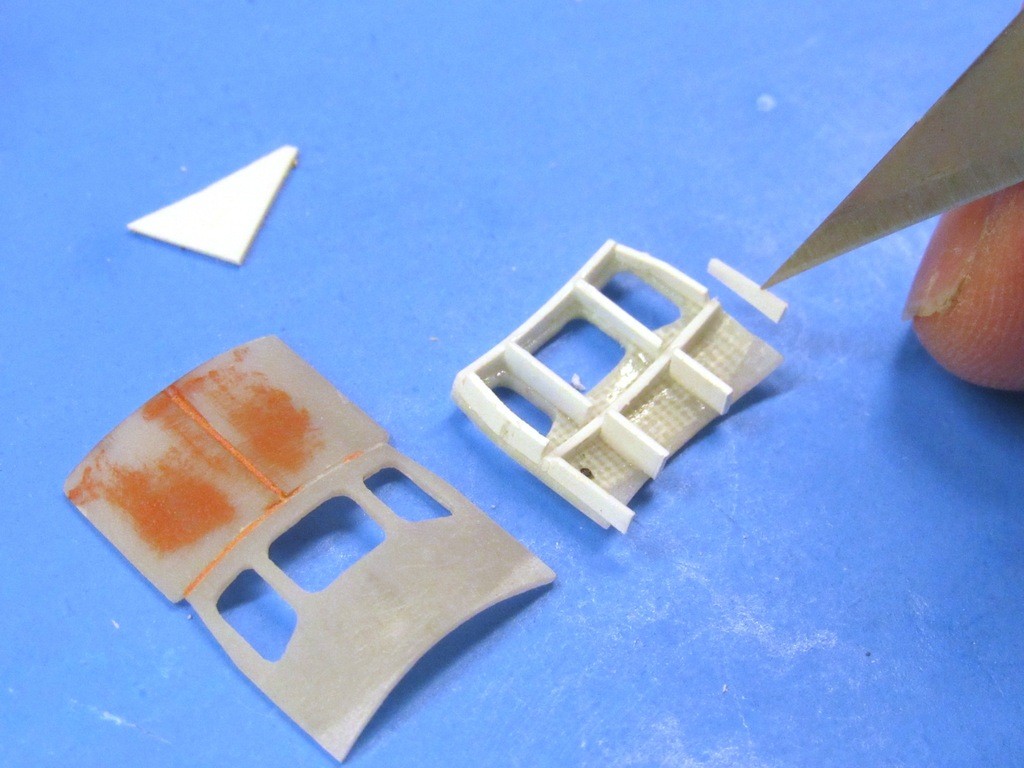

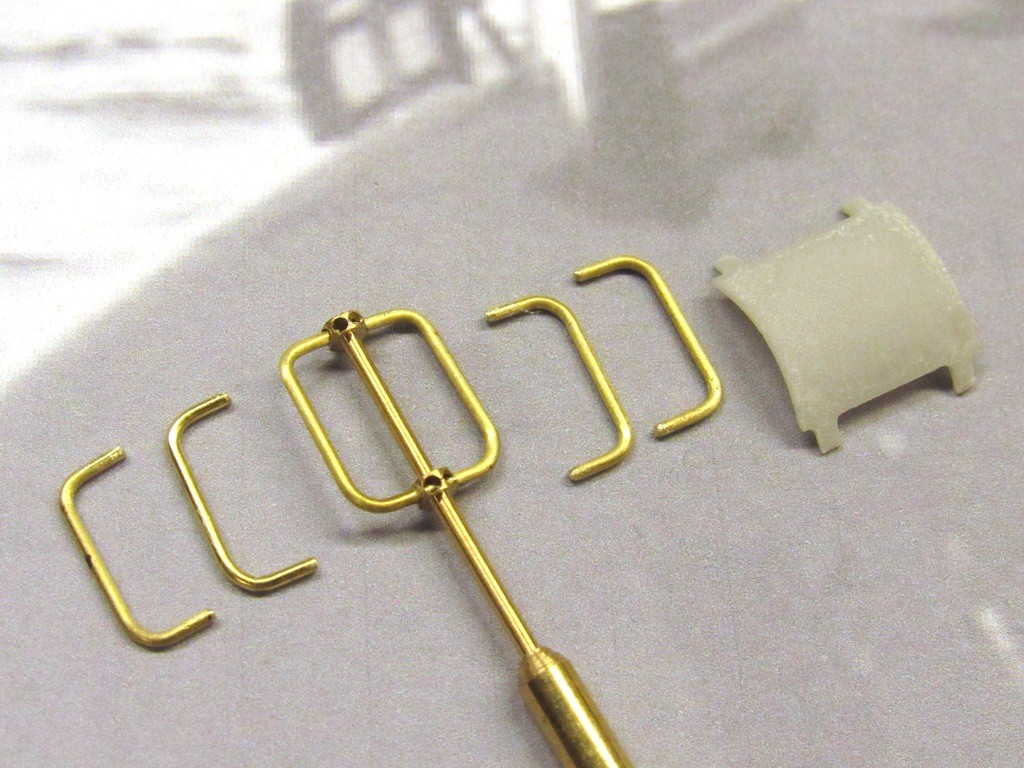

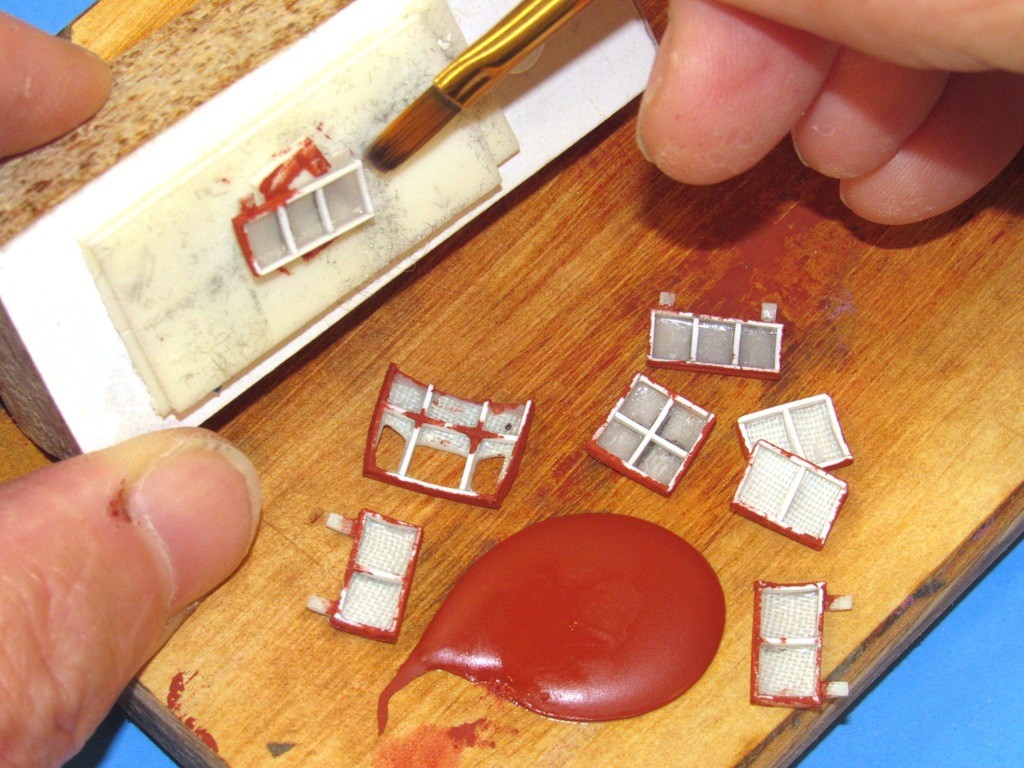

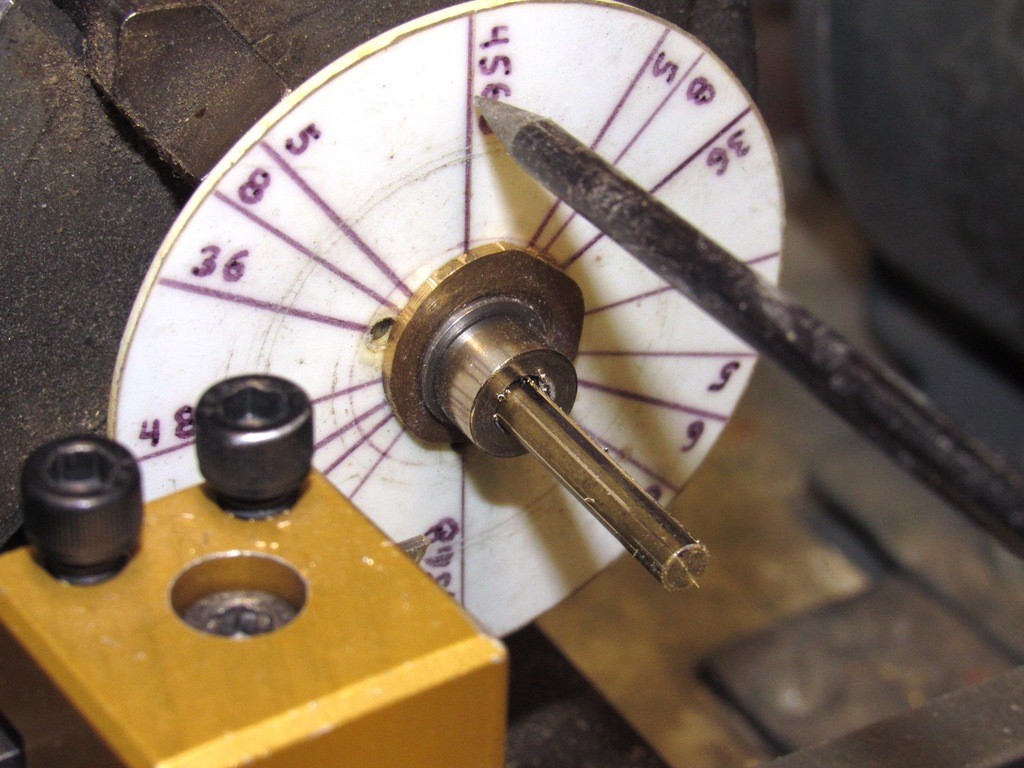

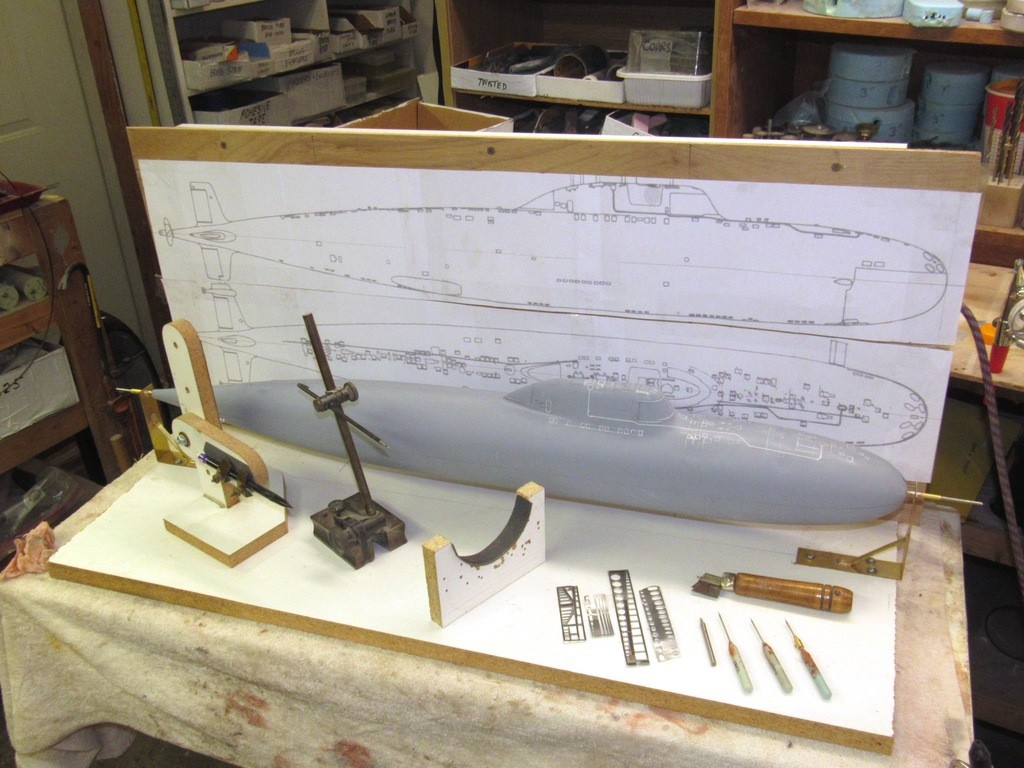

All this work dedicated to the fabrication of masters, tools, and parts needed to flesh out the 1/96 Scale Shipyard ALFA kit. Almost there!

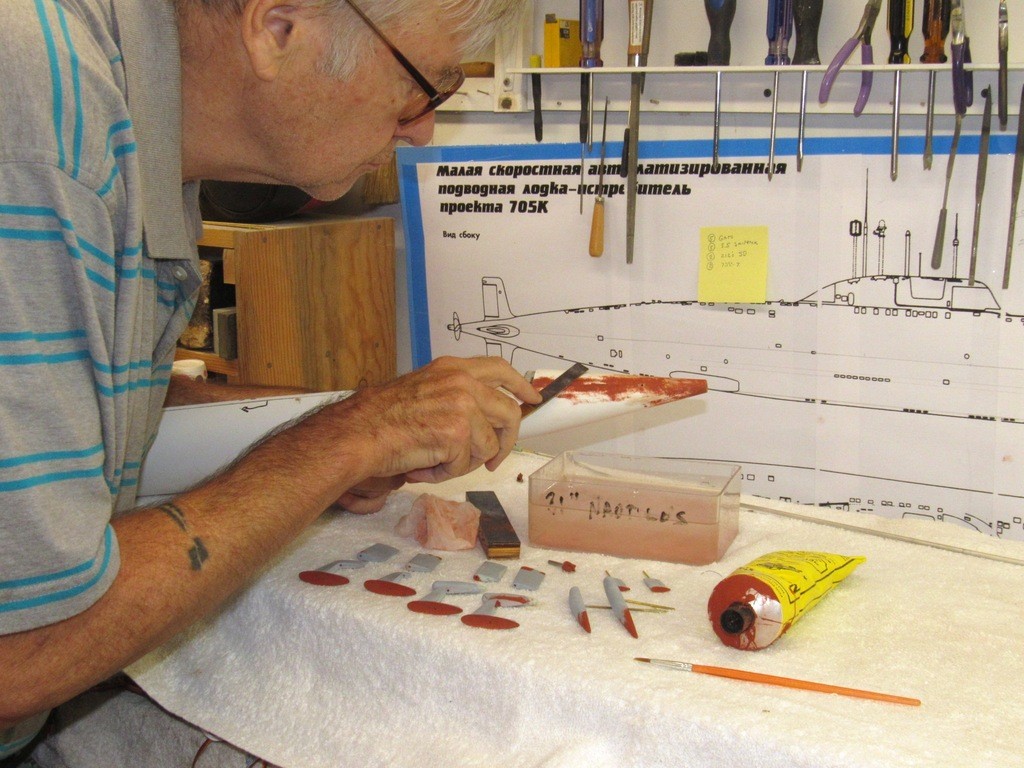

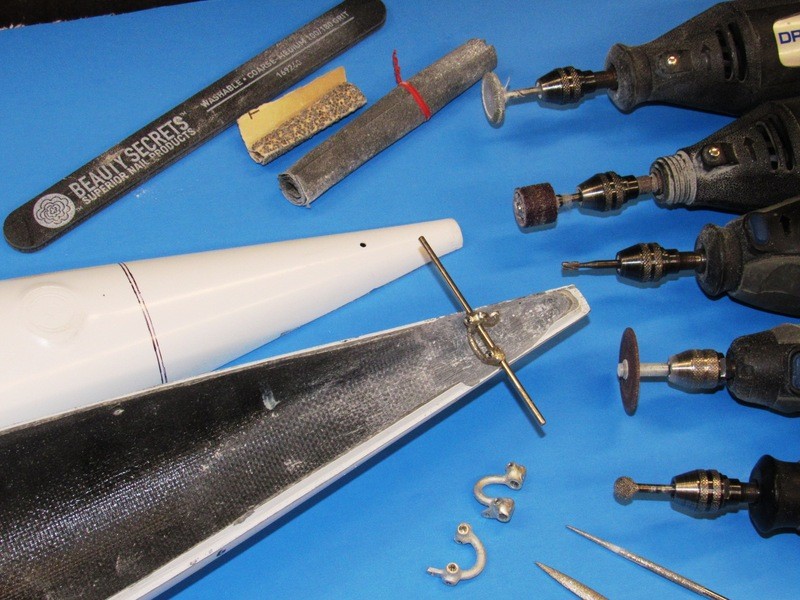

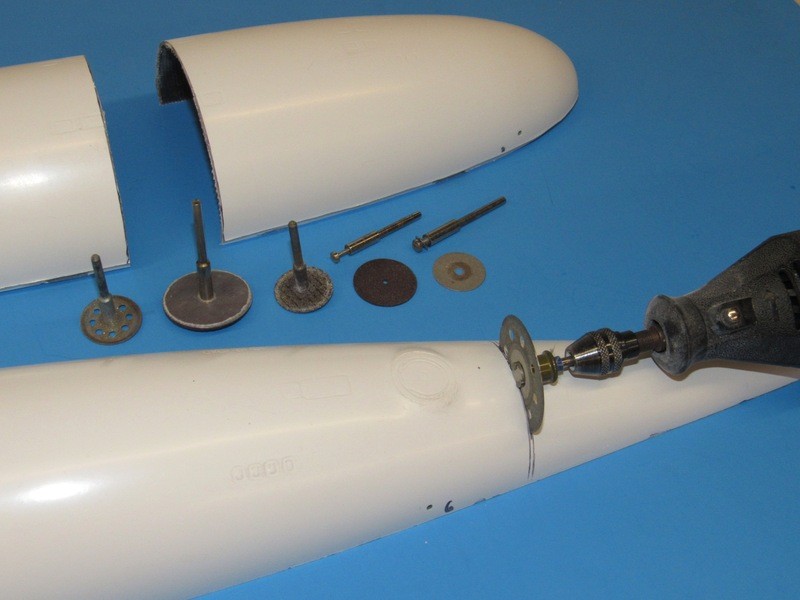

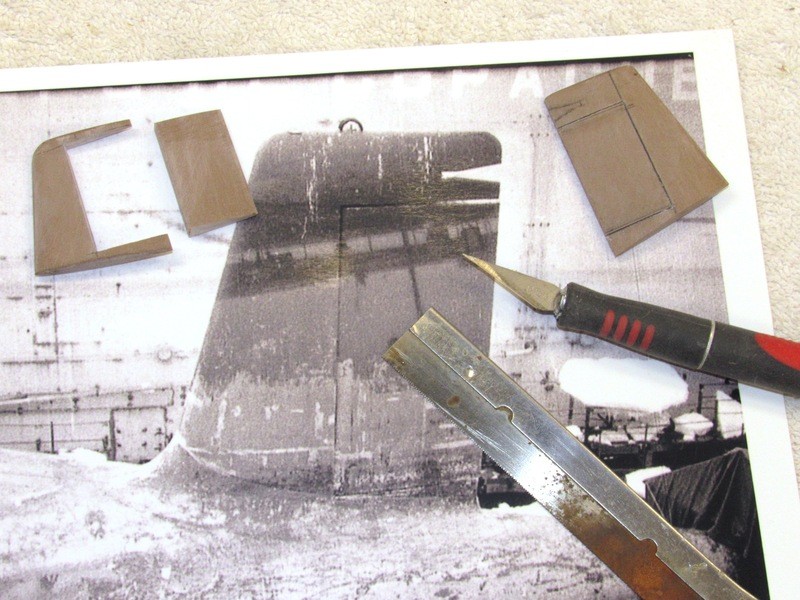

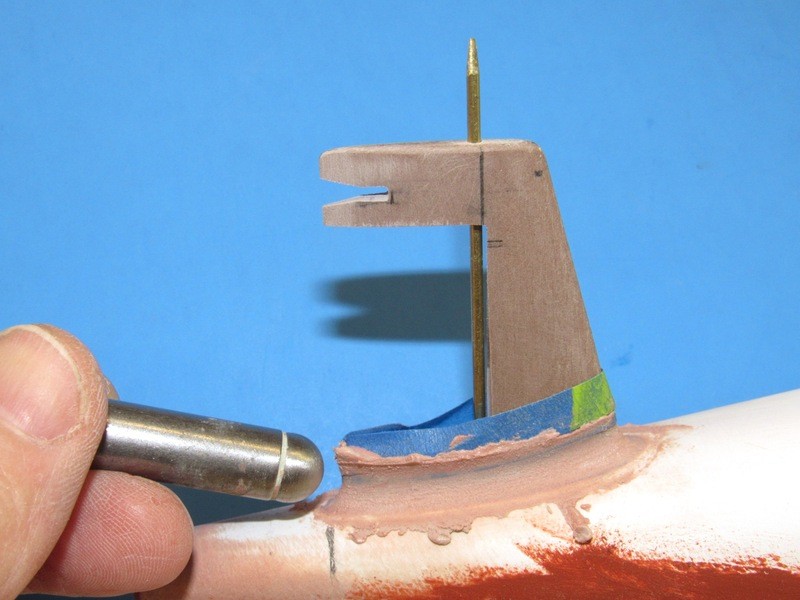

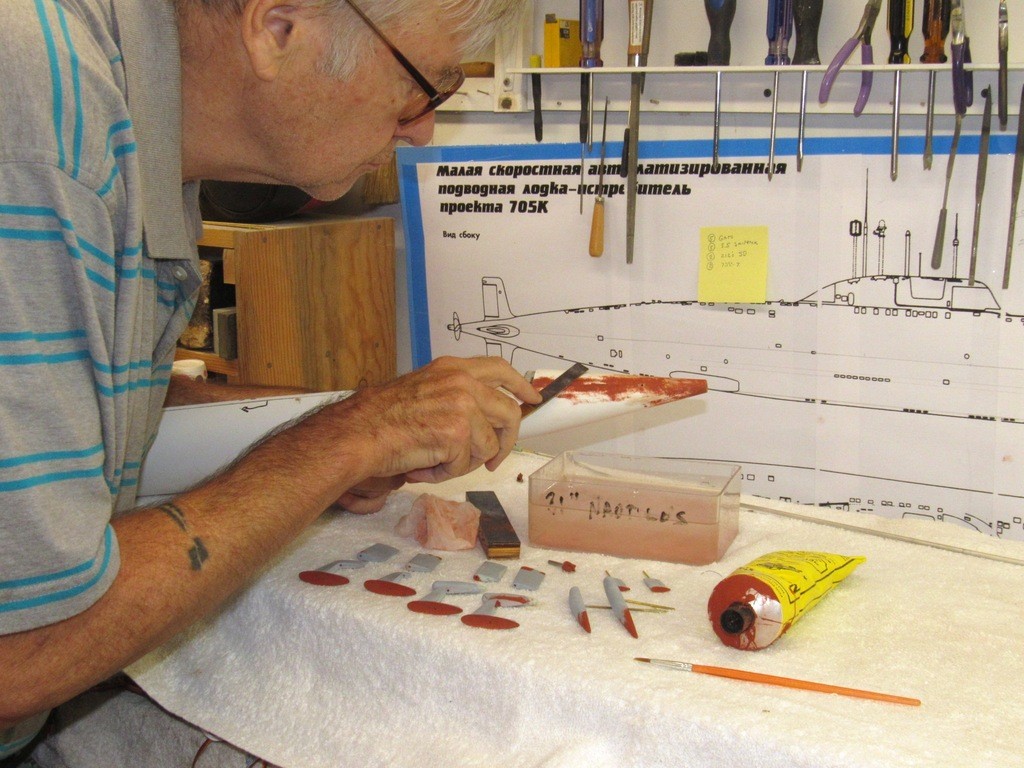

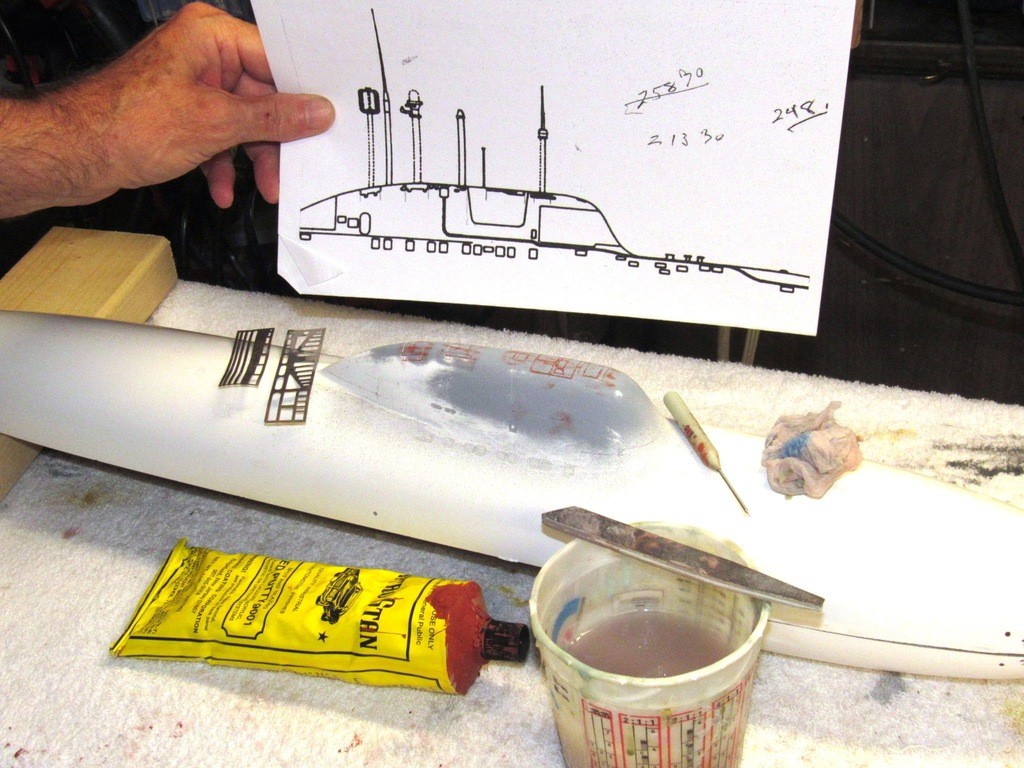

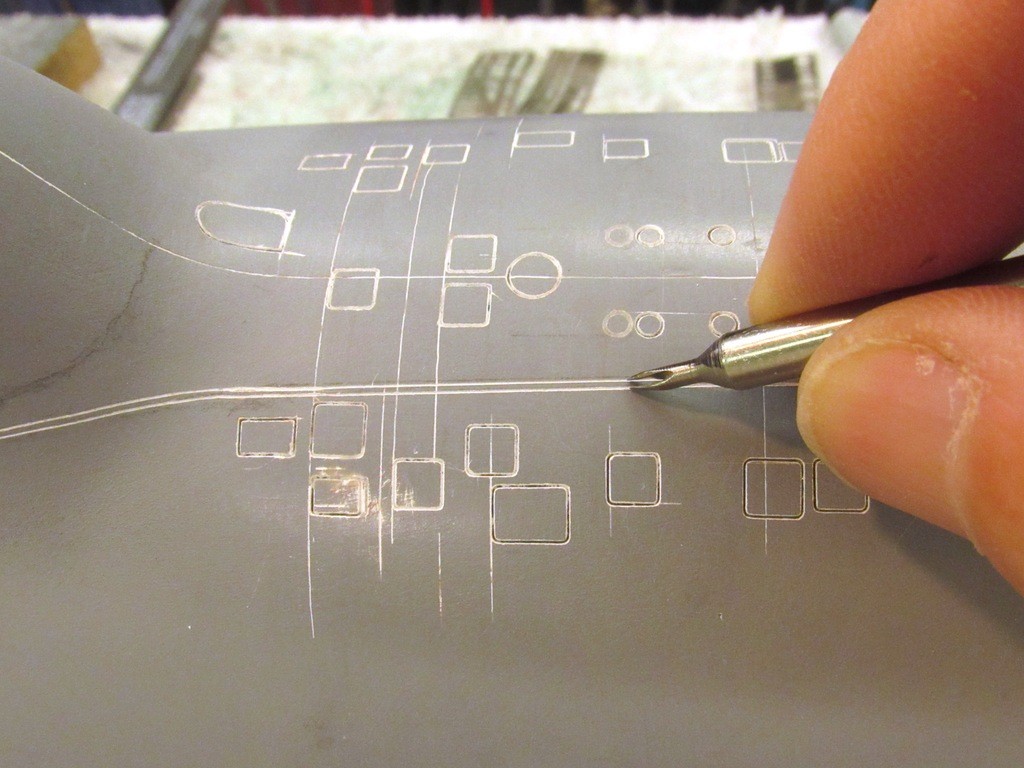

Here I’m wet sanding the stern tapper of the hull. Best tool for simple curves like this is the sanding block or, as seen here, a length of stiff brass strip with sandpaper glued to its face. But, most of the work pictured here was the filling of file-marks, dings, and gaps found on the appendage masters with Nitro-Stan air-dry touch-up putty. The flaws revealed after spraying on the initial coat of gray primer.

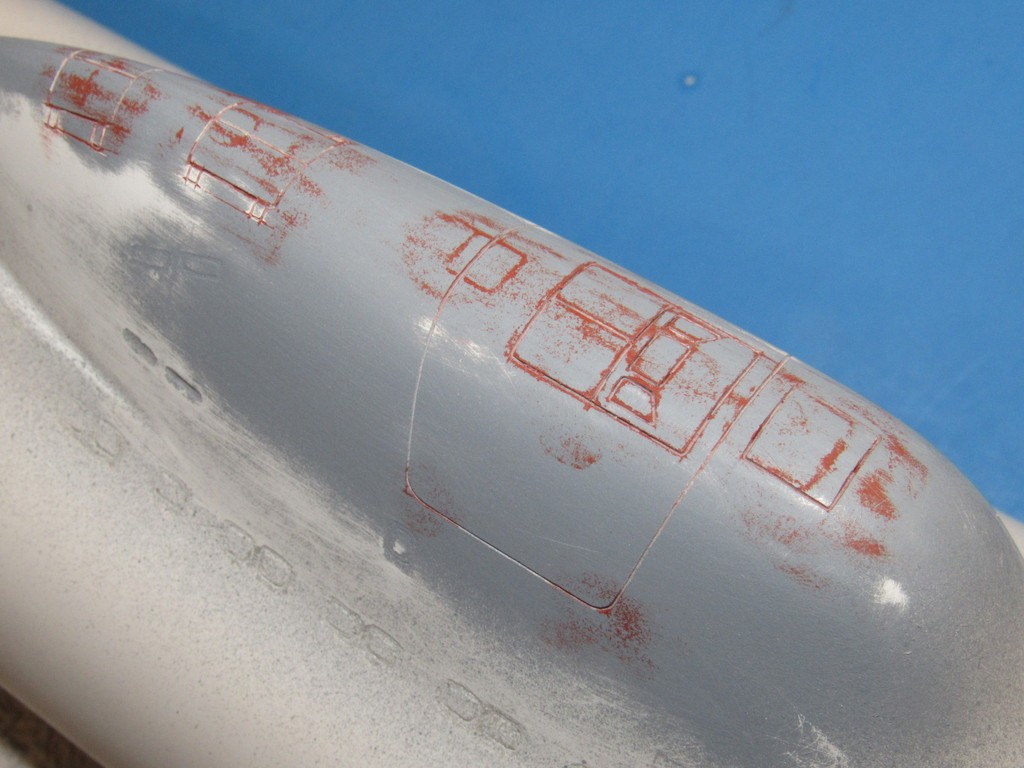

The hardened putty was abraded down with various sanding tools ranging in grits from #400 to #600, the #600 grit producing scratches small enough to be easily filled by a moderate coat of primer. All sanding at this stage is done wet: the work is either dunked in water or water applied with a wet paper towel, and the sanding tool dunked in water periodically to keep the cutting surface clear of abraded particles.

Abrasion: the process and tools is such an important and varied topic that I’ve gone out of my way in this installment to give the subject special attention. Abrasion is so much more than scrubbing a models surface with a loose piece of handy sandpaper and calling it a day!

I pride myself on exacting adherence to shape, symmetry, and smoothness of finish, be the work a master or the display piece itself. This achieved by the proper use of tools. Tools designed for specific jobs; coupled with the wisdom, (acquisition of information and practice of process) to chose the correct tool for the specific job at hand, and the ability to create tools when none are at hand. Understanding the many types and grades of grit; physical characteristics of the grit backing; ability to form the abrasive to cut as directed; and to have developed the motor-skills needed to work these tools with exactness is a prerequisite.

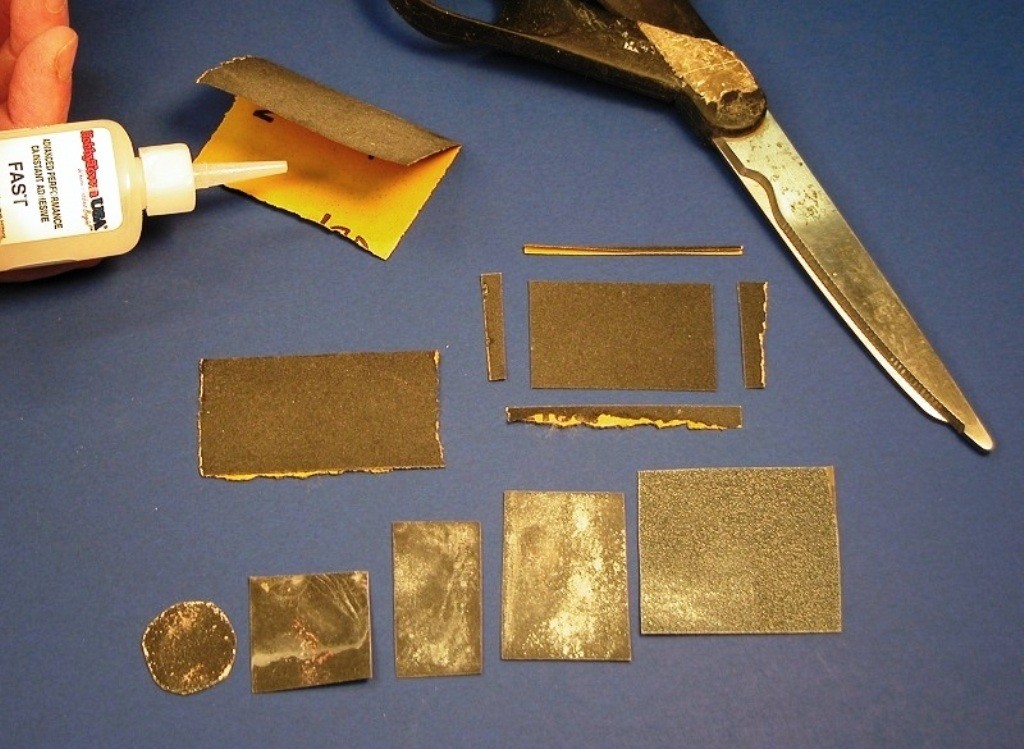

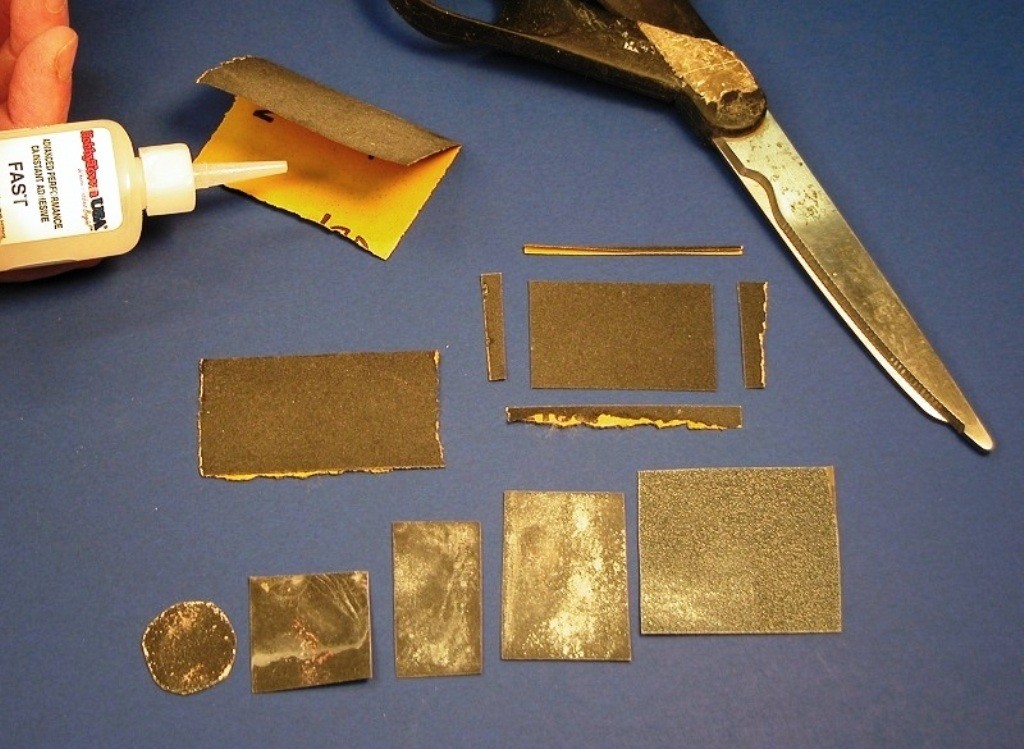

Below is some of the specialized abrasion tools formed from sandpaper. Various small, stiff sanding blocks of flat, simple, and compound curved shape; stiff double-sided sanding pieces; twisted sanding tools for radius cutting; and end-cuts of raw sandpaper of various grit grades ready to be turned into a specific tool.

In the old days the only commercially available sanding sticks were the ones sold as nail-files, and most of those of unknown grit and quality.

Today, there is a wide range of commercially available sanding sticks featuring pliable backings. These sanding sticks have as their core a material that ranges from reasonably stiff to spongy soft. They feature materials that are water resistant and are stout enough to give long service, wet or dry. These sanding sticks can be re-surfaced with another layer of grit if the need arises.

A tip: If you can find a bag full of sanding sticks of the grit and size you need from the down-town beauty-supply house, then get them in bulk from that source as the local hobby shop will charge you two-bucks for a single stick of the same thing -- why pay more if you don’t have to?

(Today’s franchise hobby-shops are only good for bad advice, magazines, r/c toys, and glue. Other than that look elsewhere for your model-building needs).

More examples of abrasives mounted in unconventional ways. Metal backed sanding blocks, soft backed sanding blocks, tubular backed sanding blocks; convex sanding sticks; rotary sanding drums; chisels (just snuck that in to see if you were paying attention); riffler and specialized jeweler’s files; steel-wool, 3M abrasive pad; twisted sandpaper; pointed abrasive coated dowels of various grits (useless!!); and specialized continuous-belt sanding sticks.

All are means of grinding away the surface of the work at hand. The trick is knowing the surface physical characteristics of the work and what abrasive tool is suitable for the job.

Polishing is abrasion, but with a much finer grit. That grit bonded to a backing like the more common varieties of sandpaper of cloth, foam, or Mylar. Or, the fine grit is suspended in a liquid vehicle such as oil or water and is applied and worked over the subject being polished with a cloth, wet stick, or polishing wheel. These specialized abrasives find little utility in the world of model ships and submarines other than rendering transparent items, bridge window, deadlights, navigation light lenses, and searchlight lenses optically transparent.

Brian Starkes, who is a Master at this game, gave me a steer to a line of contact-adhesive backed rolls of sandpaper of various grits – those four rolls you see in the upper right of the picture below. This is a neat product and permits you to quickly mount it to a stick or dowel in seconds. Brian owns and operates a big-time automotive refinishing shop and he’s taught me a lot about abrasive use and sources of supply over the years. And his model work has to be seen to be believed!

https://forum.rc-sub.com/forum/builder-threads/133616-1-72-sturgeon

A sanding block can be a simple stick of square wood with some loose sandpaper wrapped around it, or it can be a commercial tool usually made from extruded T-section aluminum. I prefer to take a length of Pine block and glue the sandpaper to one or more faces with the aid of contact cement. Being the impatient sort I accelerate the drying of the spray applied contact-cement with a heat-gun.

When a foam-backed sanding stick gets worn down, I’ll apply contact cement to the worn face and slap on a fresh piece of sandpaper. Never throw out a sanding stick – you can always breathe new life into it.

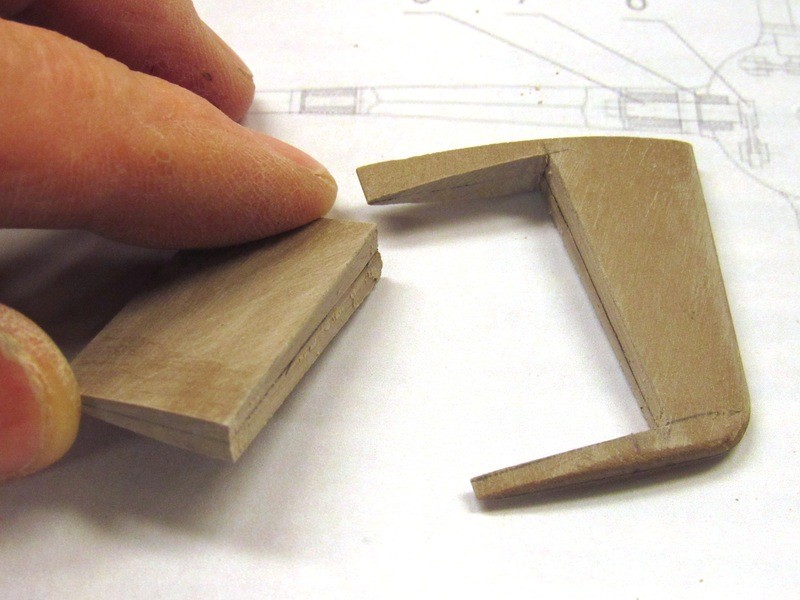

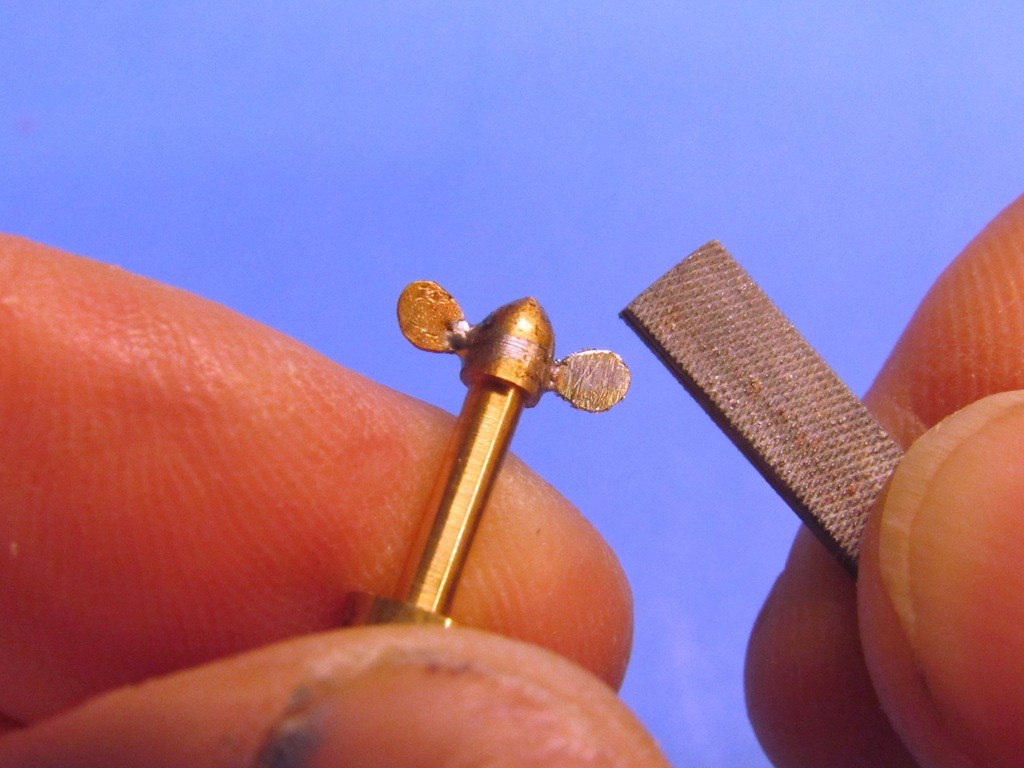

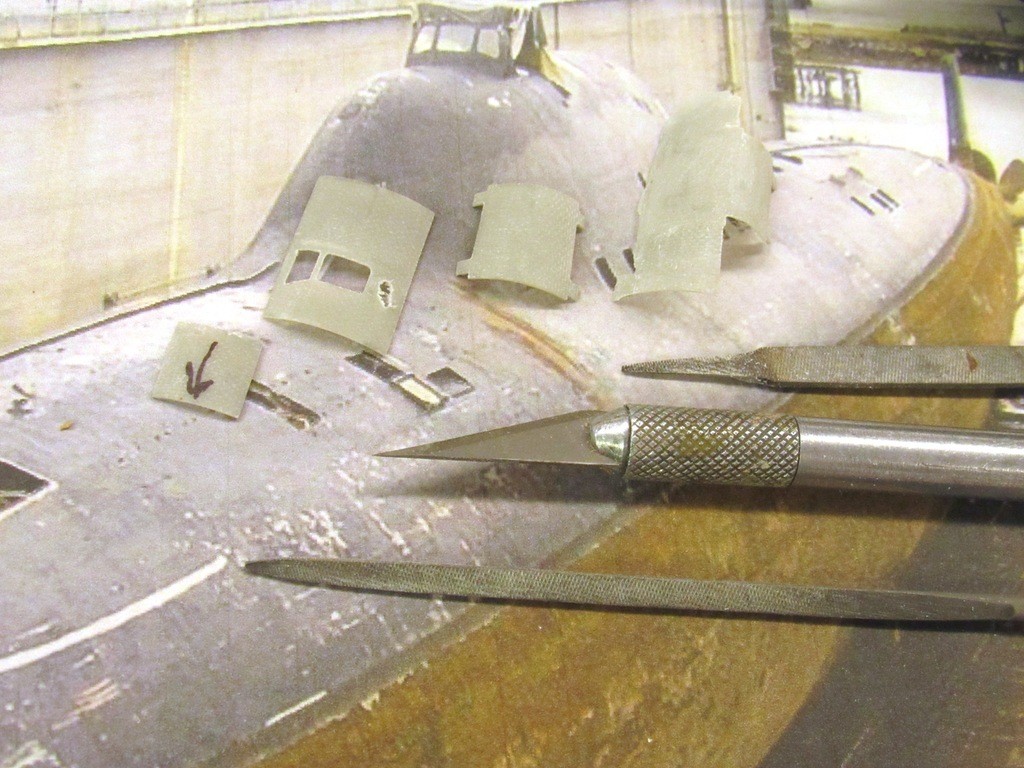

Today’s sanding sticks, owing to their pliable cores, have enough give to make sanding of compound (complex) curves an easy matter. However, where you need a stiff, thin-sectioned abrasive tool to get into tight places and cut corners or edges with precision, double-sided sanding strips are the way to go.

A double-sided sanding strip is made by selecting the grit you need, folding the sandpaper in half (cloth and mylar backed grit can be used this way too, but is more difficult to glue and not nearly as stiff as glue saturated paper), hitting its backside with CA accelerator, applying CA to the other half, and quickly folding over and sandwiching the joined halves under a weight and flat surface till the glue cures hard.

The stiff sanding strip is cut with scissors to any shape that the job dictates.

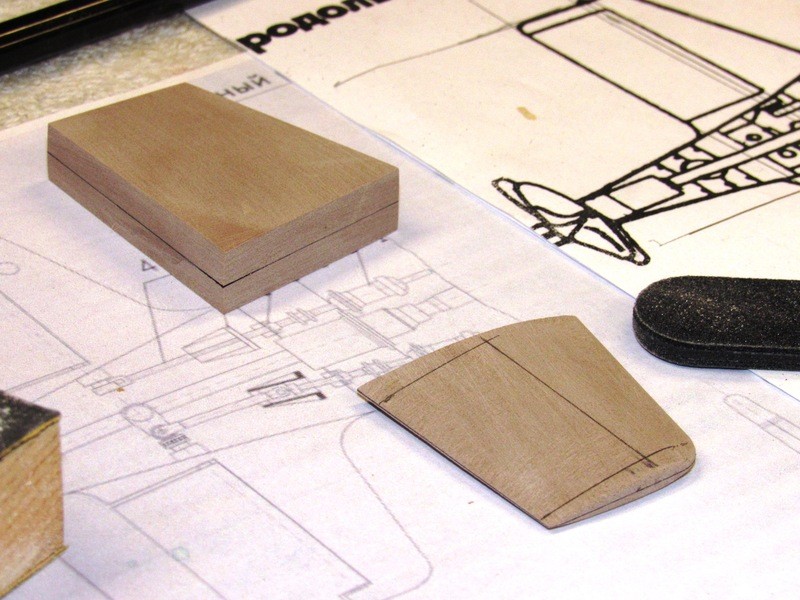

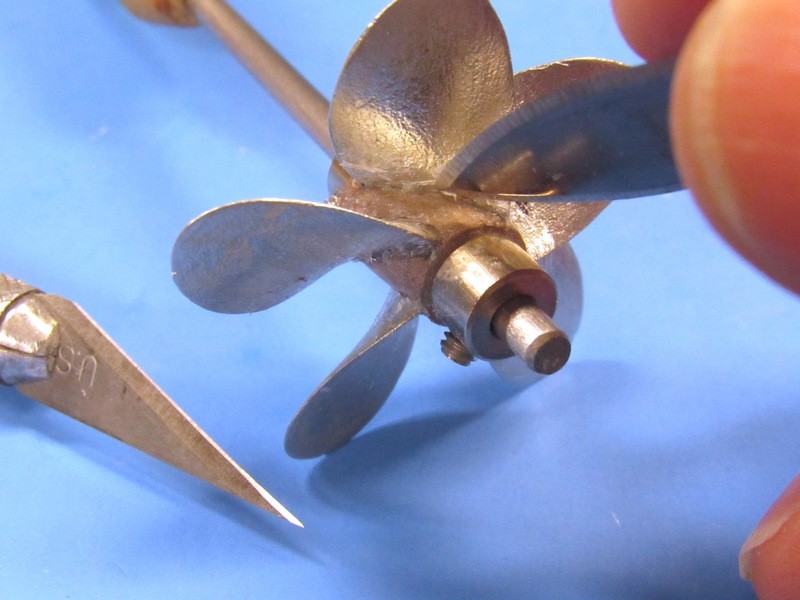

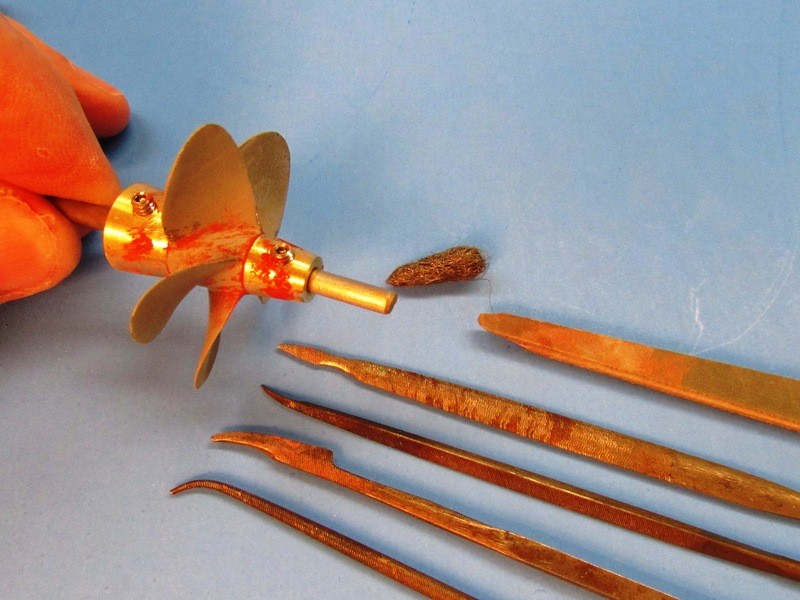

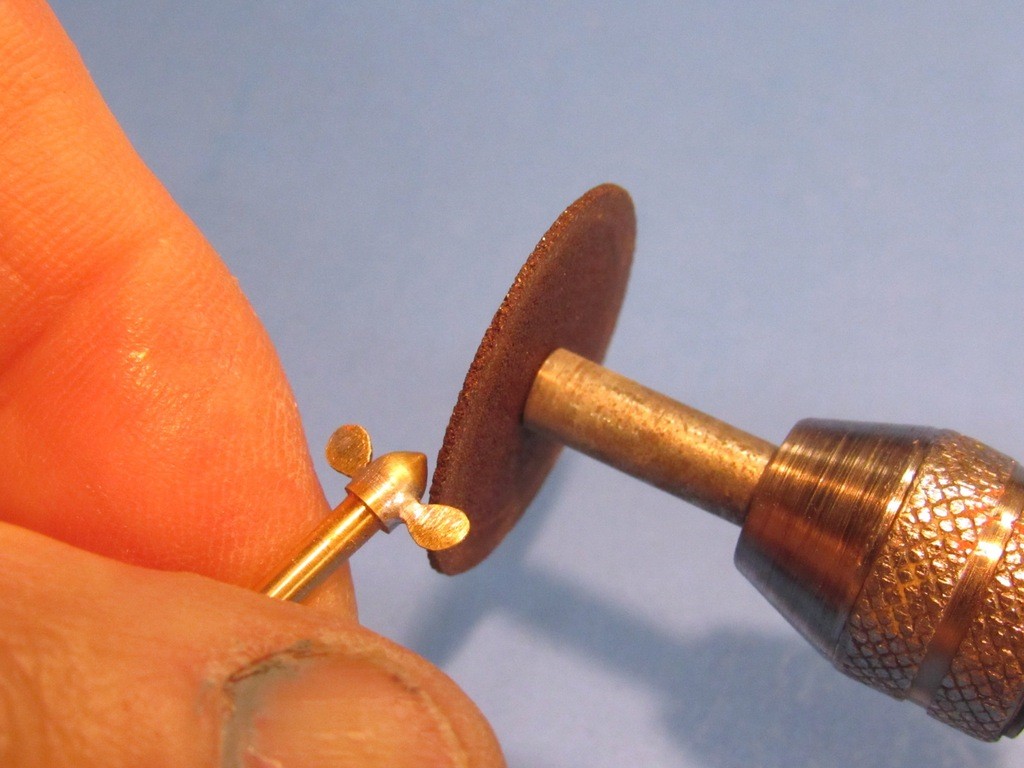

As I demonstrated with the propeller blade-hub fillet work, there are occasions where you have to get around nearby structures to dig in where you need to abrade material away. Small files with exotically curved ends are sometimes the answer. And over the years these ‘riffler files’ have served me well in a variety of unique and otherwise impossible to do abrasion jobs.

You can buy them commercially, but you are at the mercy of a pre-packaged file cut pattern, size and shape of curvature – often these store-bought rifflers just won’t do the job. So, to develop a tool best suited to a particular task, you take a common jeweler’s file of the desired cut and cross-section and give it a tip curve suited to the job at hand. You make your own riffler file. And when the job is done you add it to your ever growing collection of specialized abrasive tools.

But, if you don’t want to be bothered forming your own, here’s a site where you can buy them: https://www.gesswein.com/c-131-rifflers.aspx

It’s easy to bend high-carbon iron tools like this: Just get the work to a deep red heat and bend as required. Quench in water and you’re good to go.

Just about the last coat of primer to go down on the appendages.

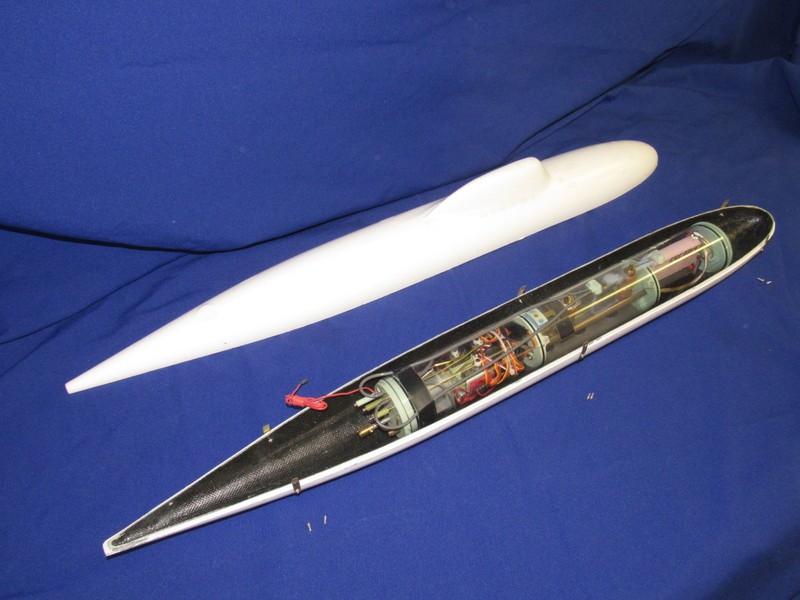

This is the first shot of primer on the hull, and that localized to the stern where I did all the radial screeding, filler, putty, and sanding work. The rest of the hull is still in the raw. I’ve faired in the forward radial gap, but have yet to do the same to the after radial gap. Once those areas are tight I’ll install ‘capture lips’ to draw the longitudinal edges of the upper and lower hull tightly together – at which point another shot of primer will be laid down to find remaining problem areas.

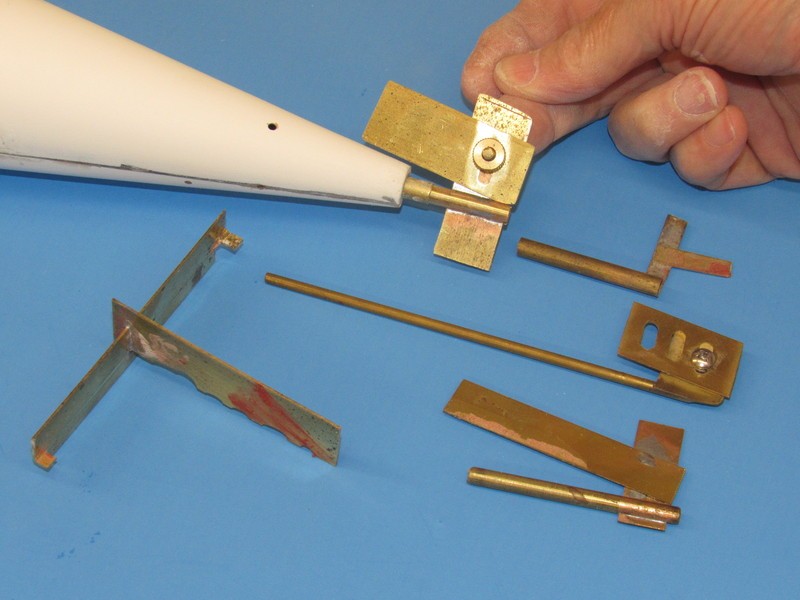

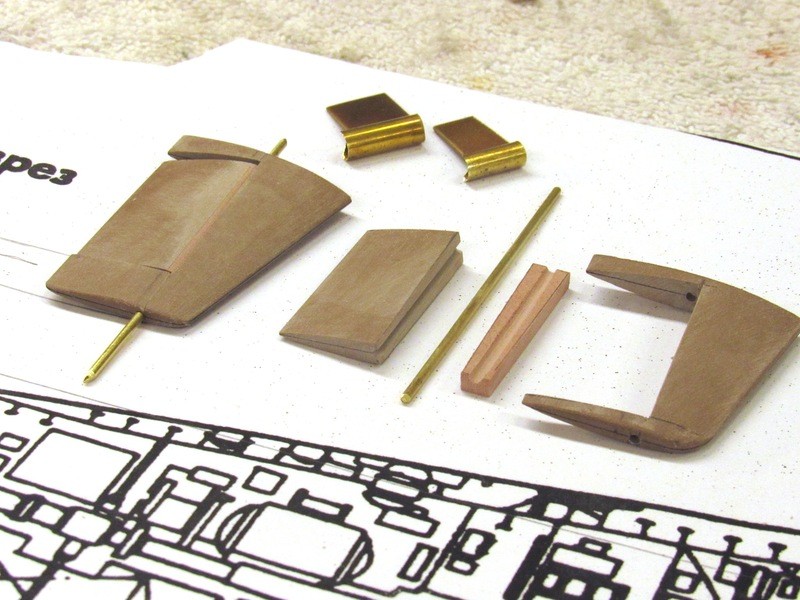

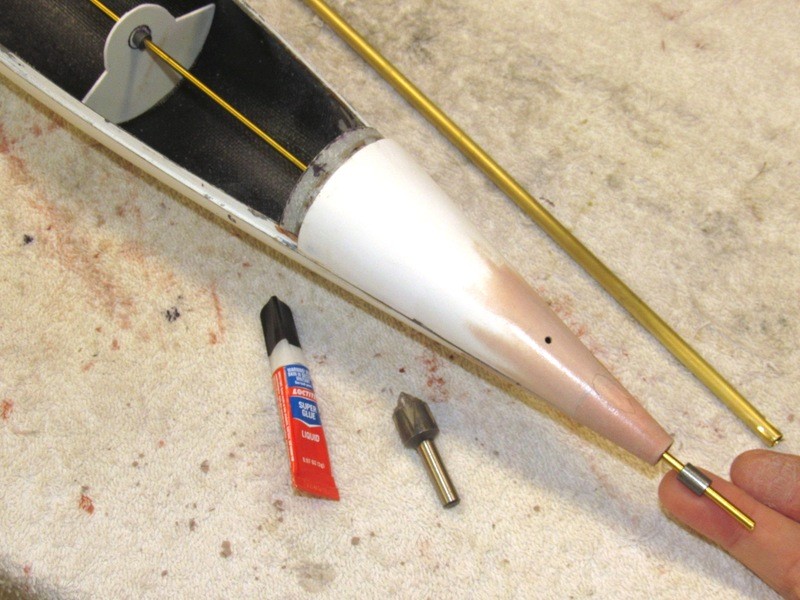

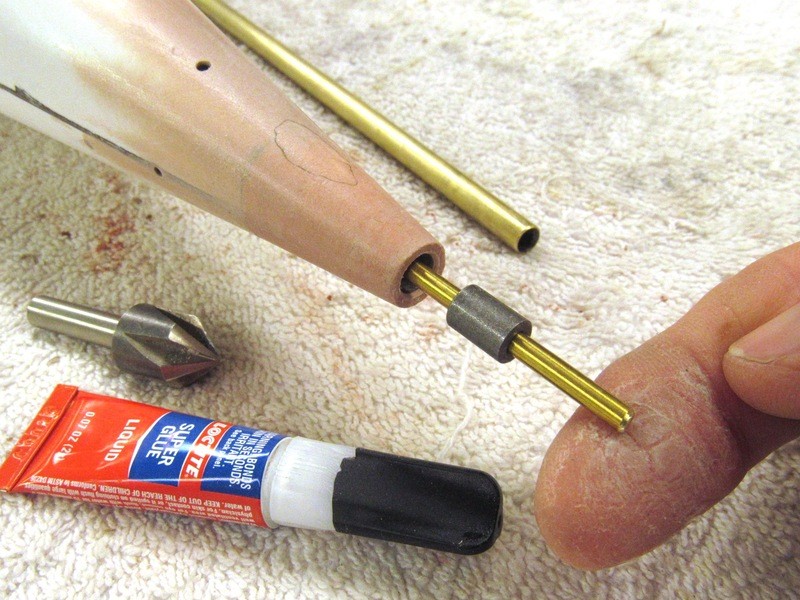

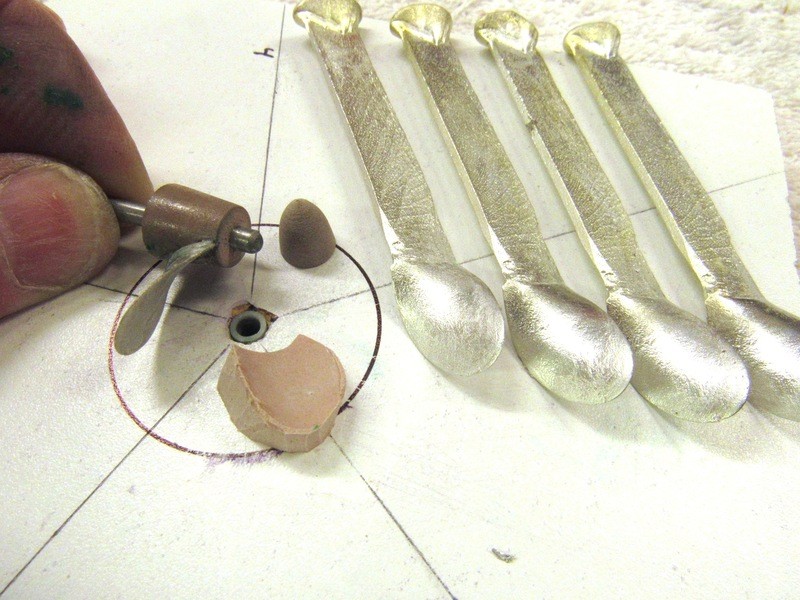

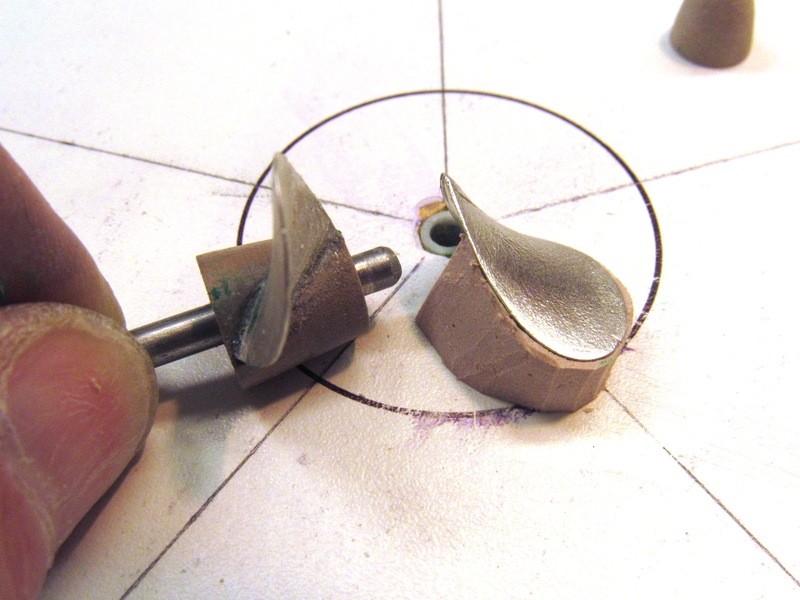

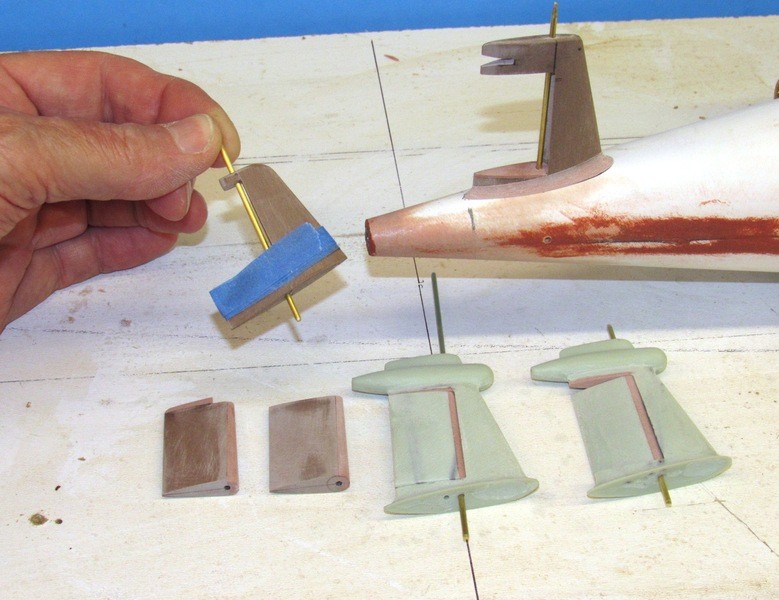

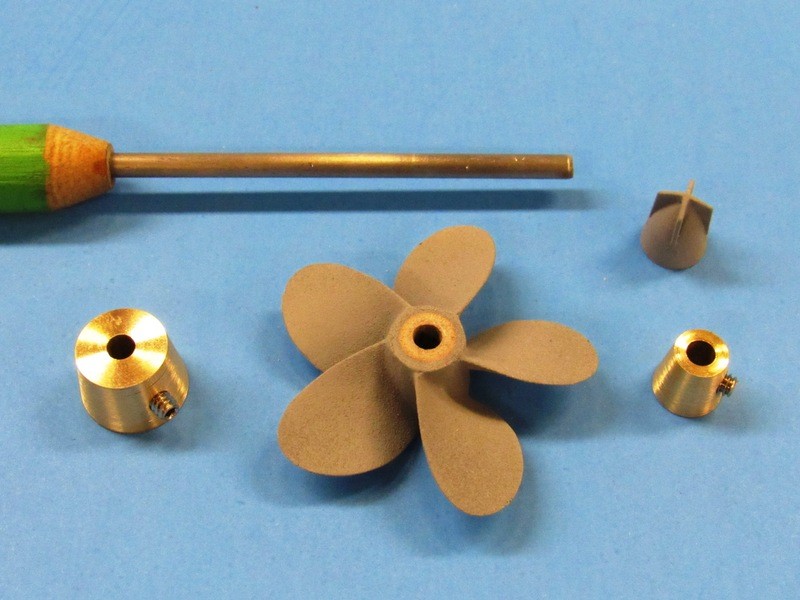

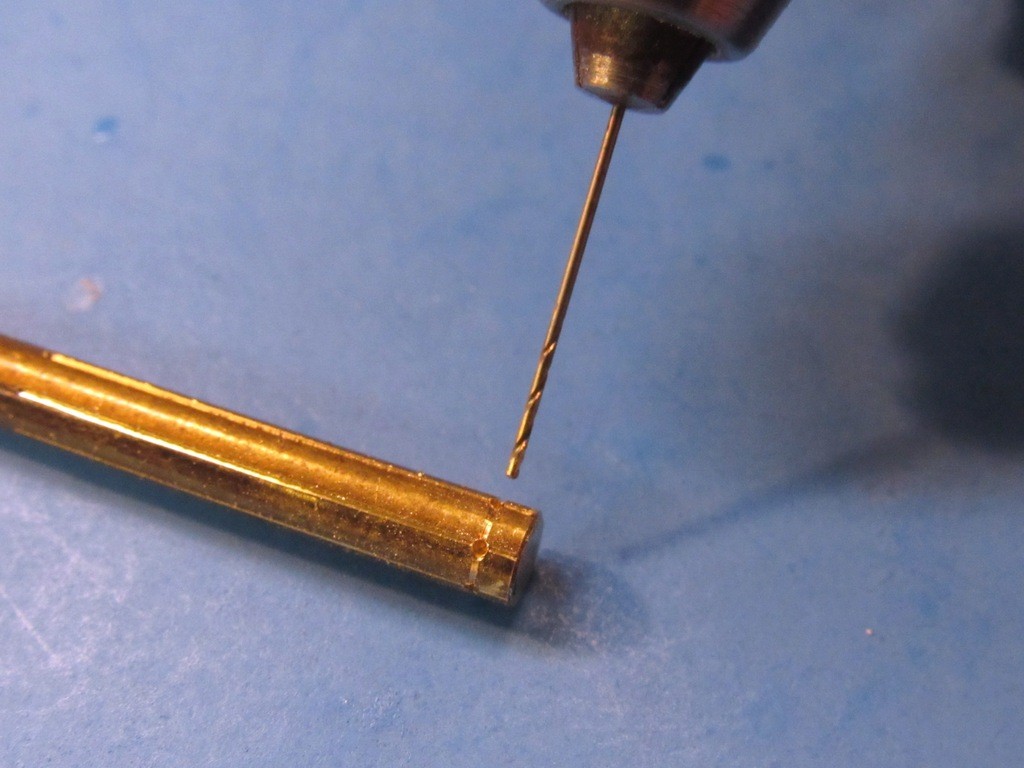

Note that each master has been outfitted with a 1/16” brass rod holding fixture. These make it easy to handle these small items during priming and conveniently slip into the open honeycomb cells of a cardboard box, suspending the work as the primer dries.

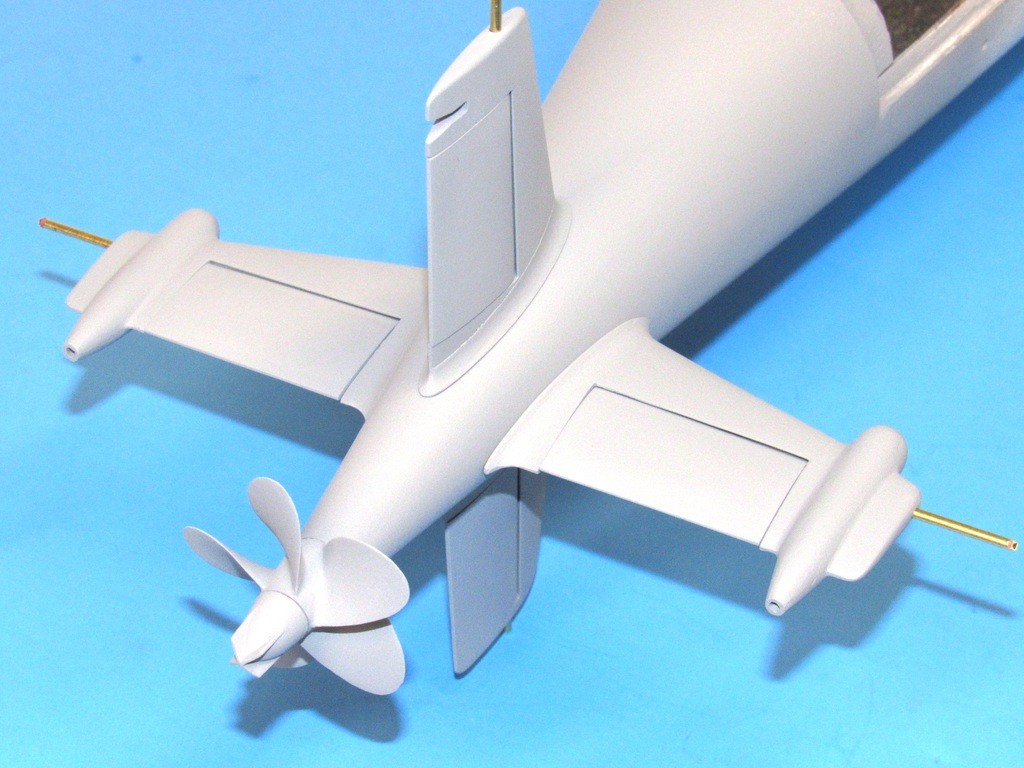

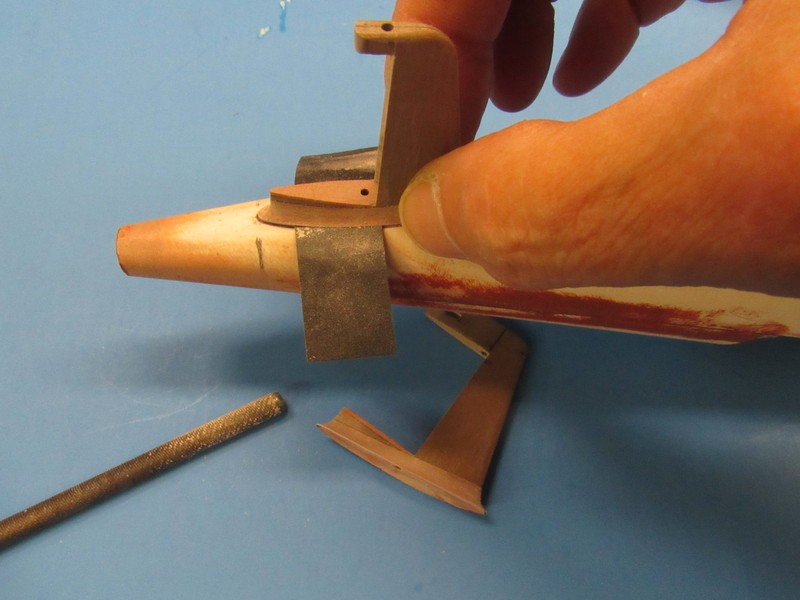

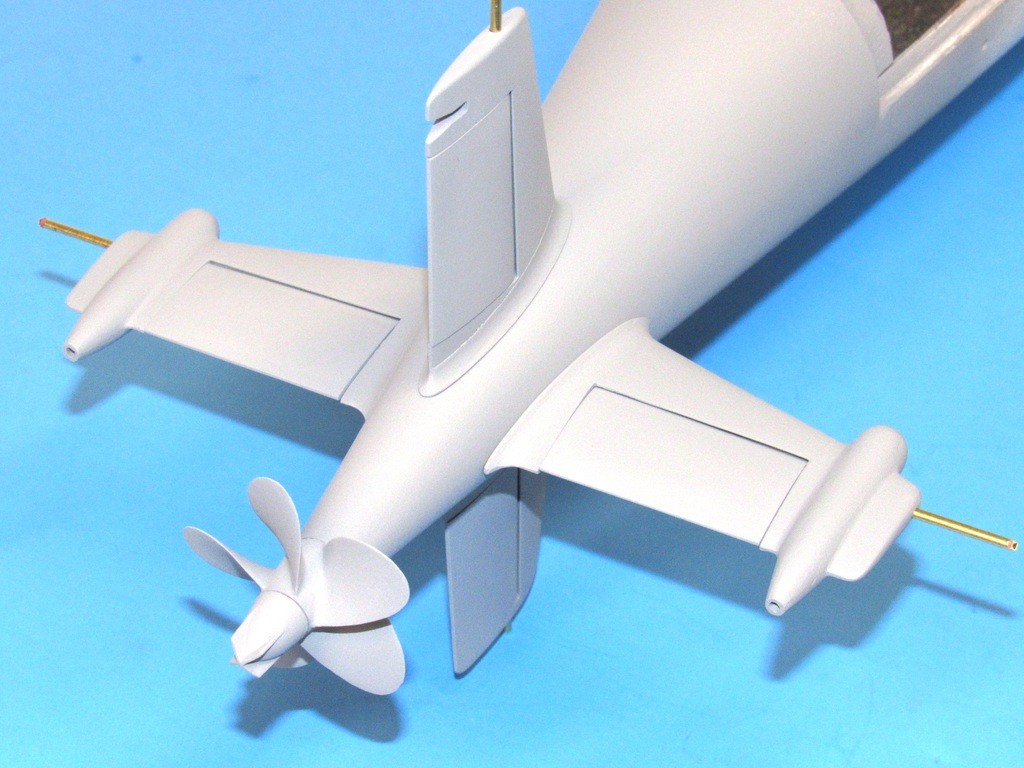

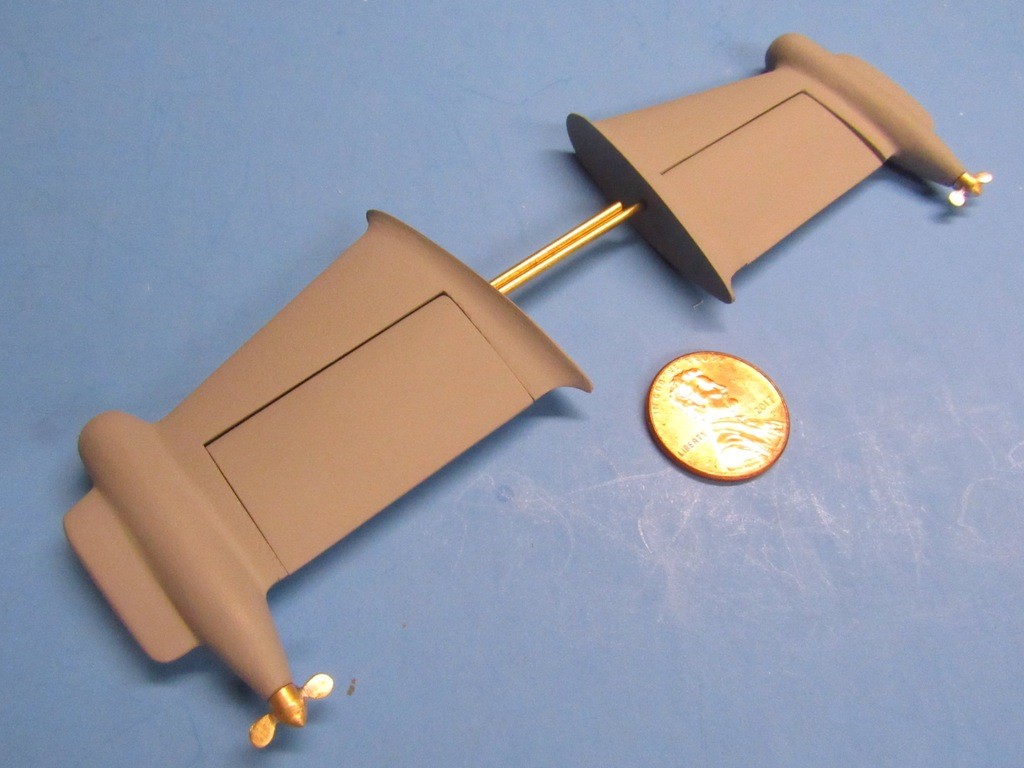

I’m sure I’m not the only one who can’t wait, once parts are nearing completion, to test-fit things together just for fun … and to examine the mock-up for symmetry and ease of fit. “Yup, looks like the ass-end of an ALFA to me!”

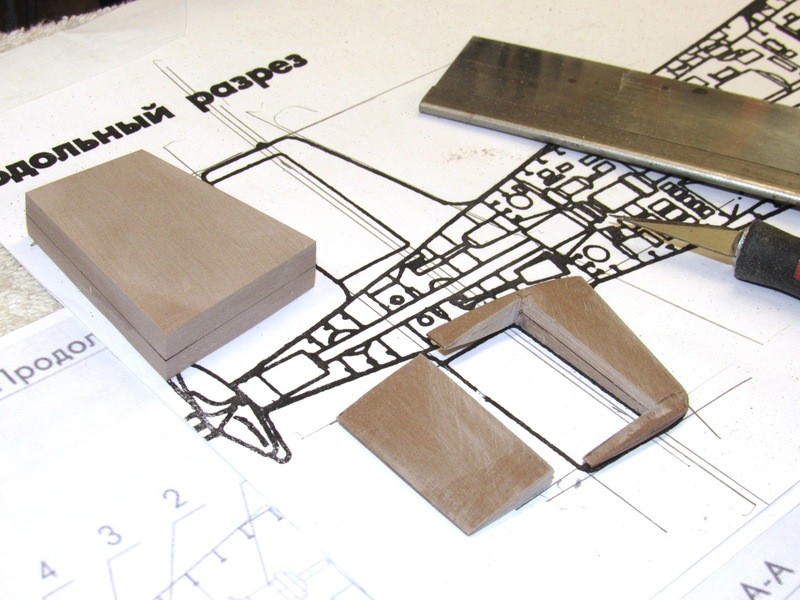

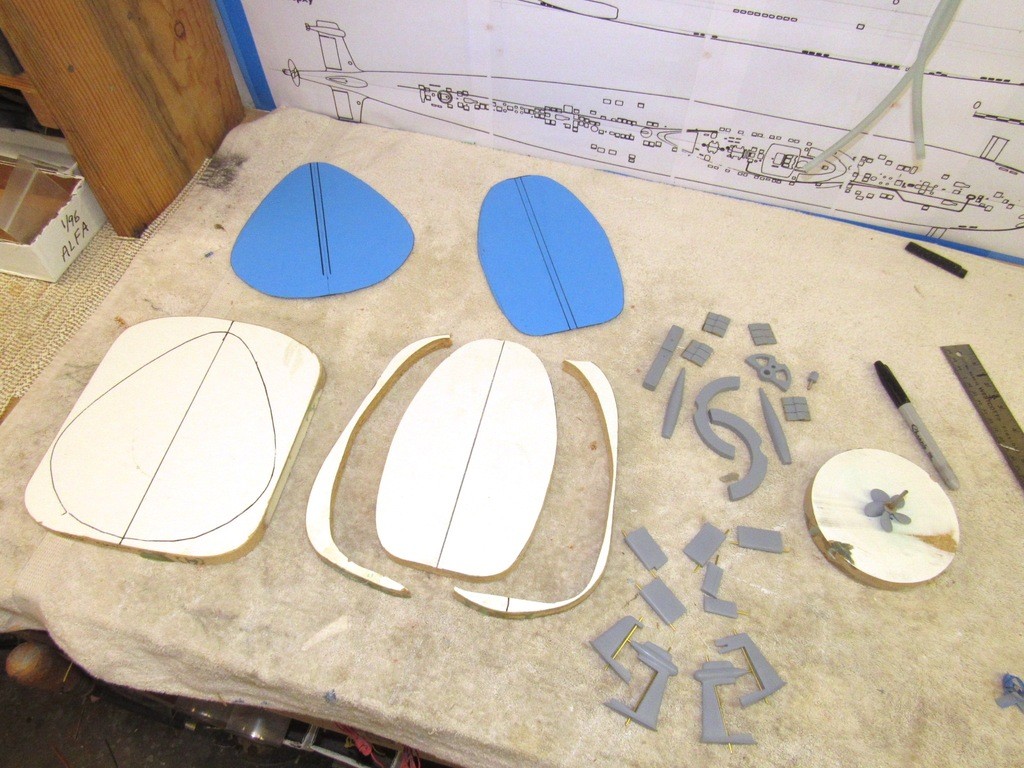

In foreground are the masters for the secondary loop condenser scoops and bow planes.

(The ALFA bow plane linkage on the eventual r/c model presents a special problem as the port and starboard planes do not fall along the same horizontal plane – they are slightly off-set from one another in height. So, I can’t just run an operating shaft between the two. I’ll likely provide an internal bearing tube for each operating shaft and use a piece of flexible tubing between them to handle the off-set between the shafts. We’ll see. Plans change as the practical installation matures in my hands. More on this little problem later.)

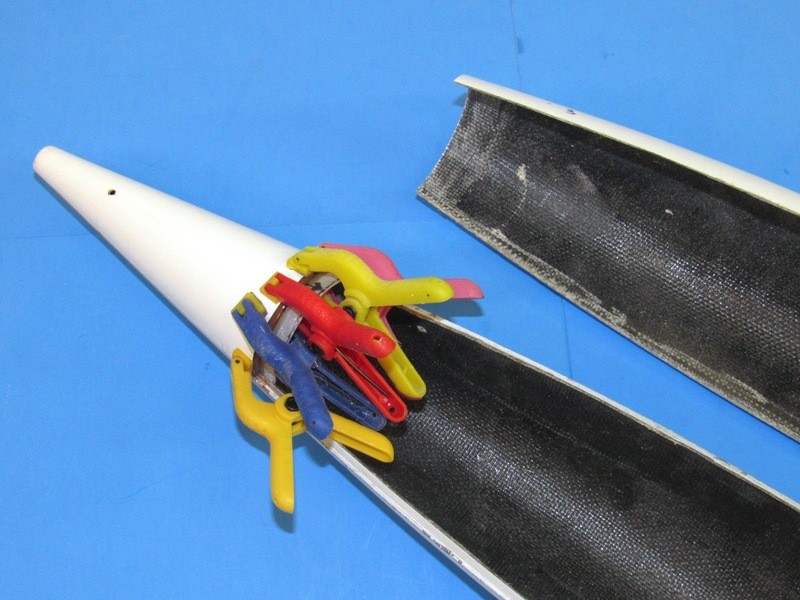

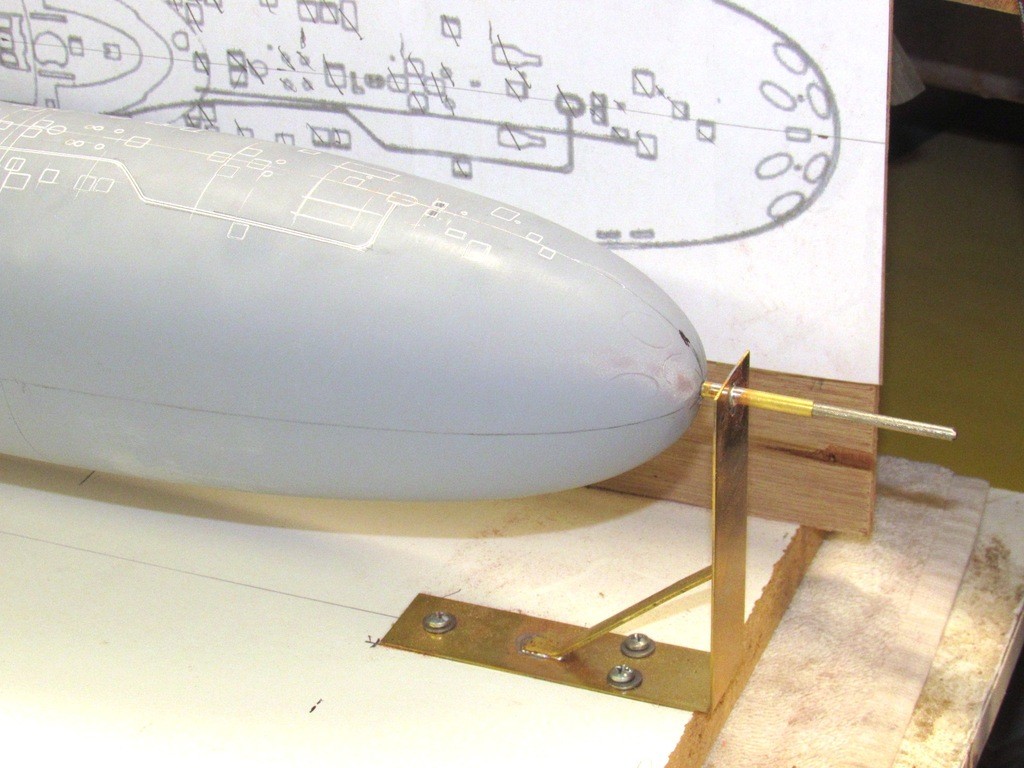

Test fitting the horizontal and vertical stabilizers without aid of tape or glue was made possible by the control surface operating shafts. The horizontal stabilizers shared a single shaft that passed through the hull. As all four operating shafts are on the same vertical plane the vertical stabilizer shafts used here for the mock-up fit only extended less than half-way into the hull till they hit the horizontally running horizontal stabilizer shaft. The arrangement was a bit wobbly, but good enough for the pictures presented here.

I’m almost ready to make tools from these appendages. Only chore remaining is to fill and sand some sanding scratches, and build up the slightly raised edge of the horizontal stabilizer fillets.

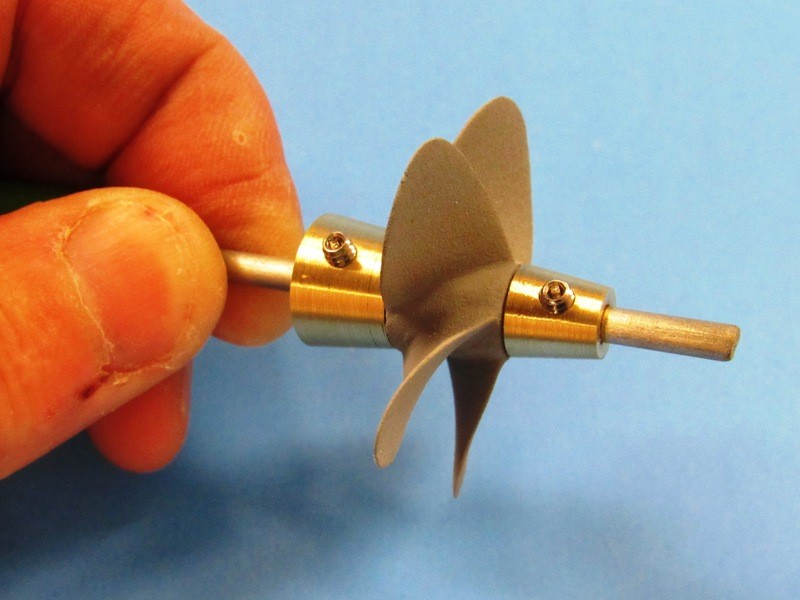

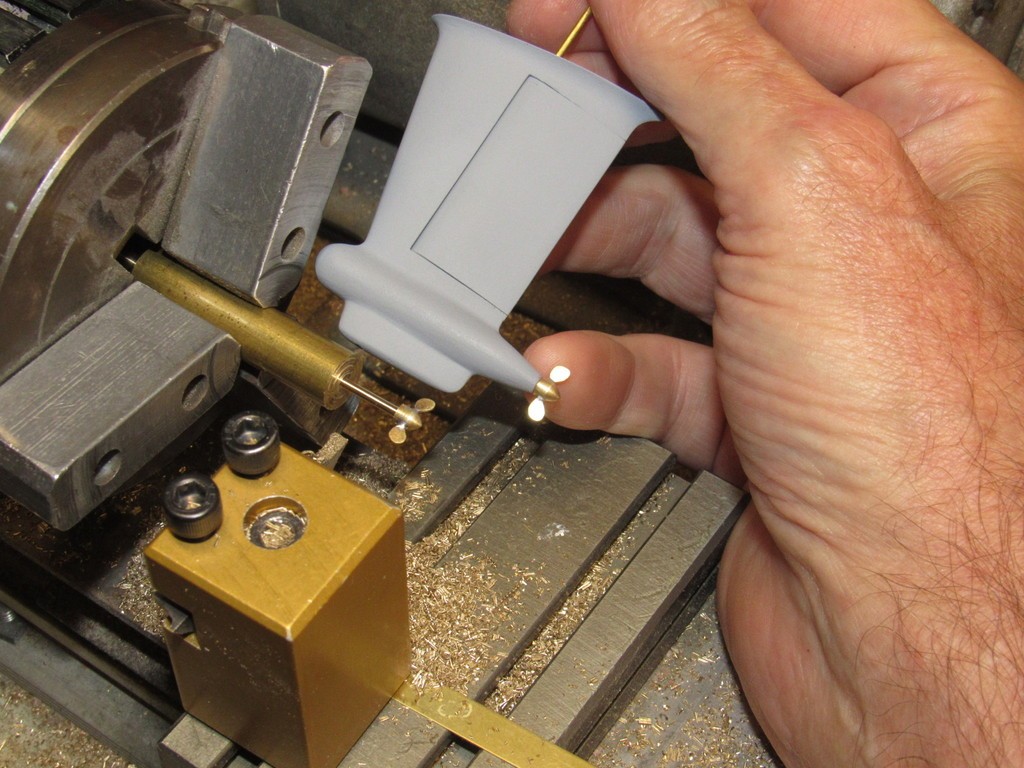

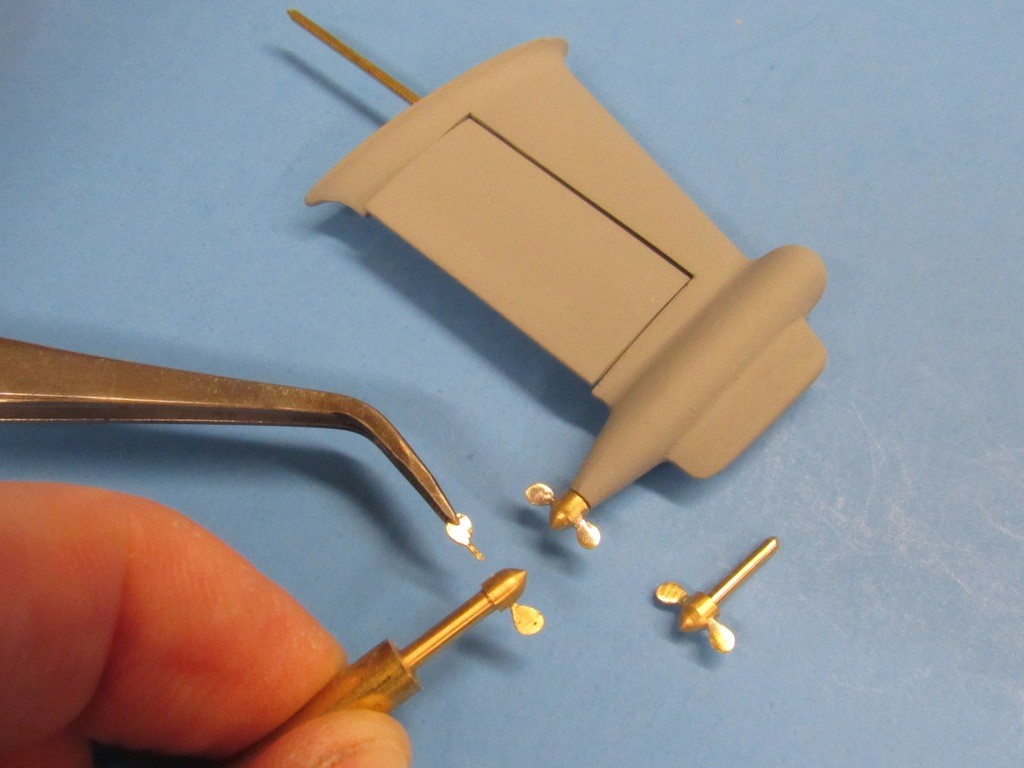

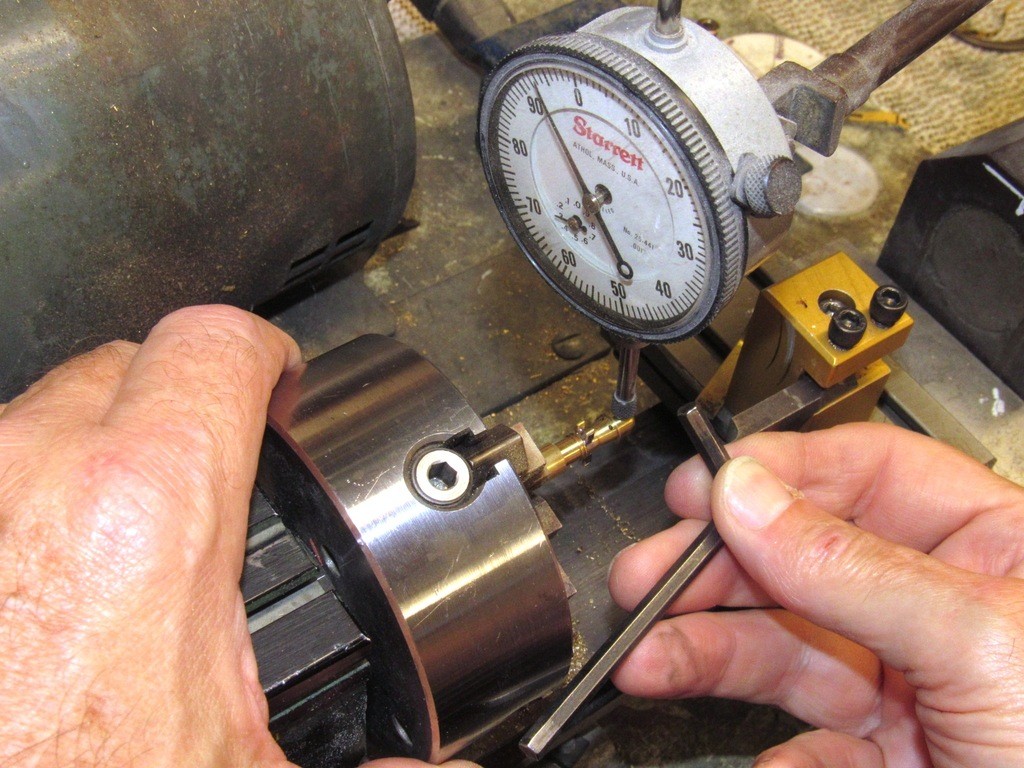

In practice the cast white-metal propeller will be secured to its propeller shaft with a 4-40 X 1/4” long set-screw. About 1/8” of shaft will project aft of the hub and the cast resin dunce-cap will be a press-fit to that.

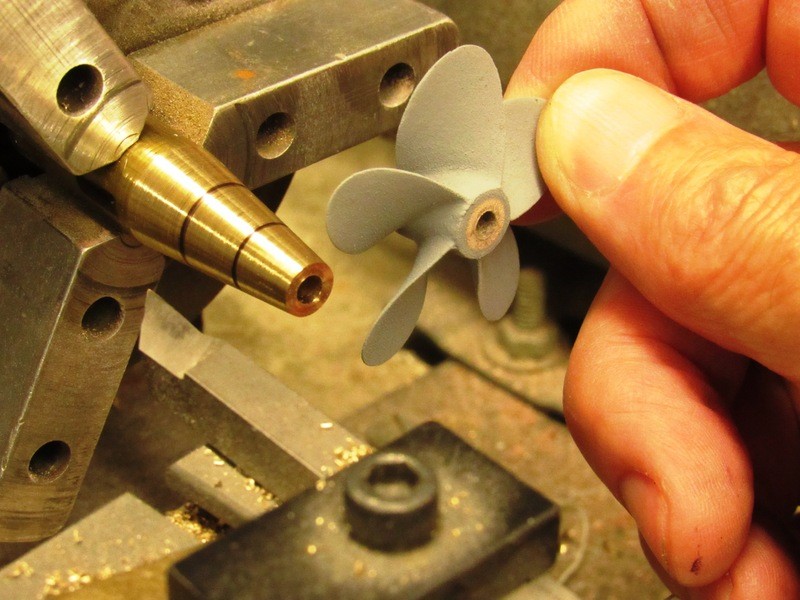

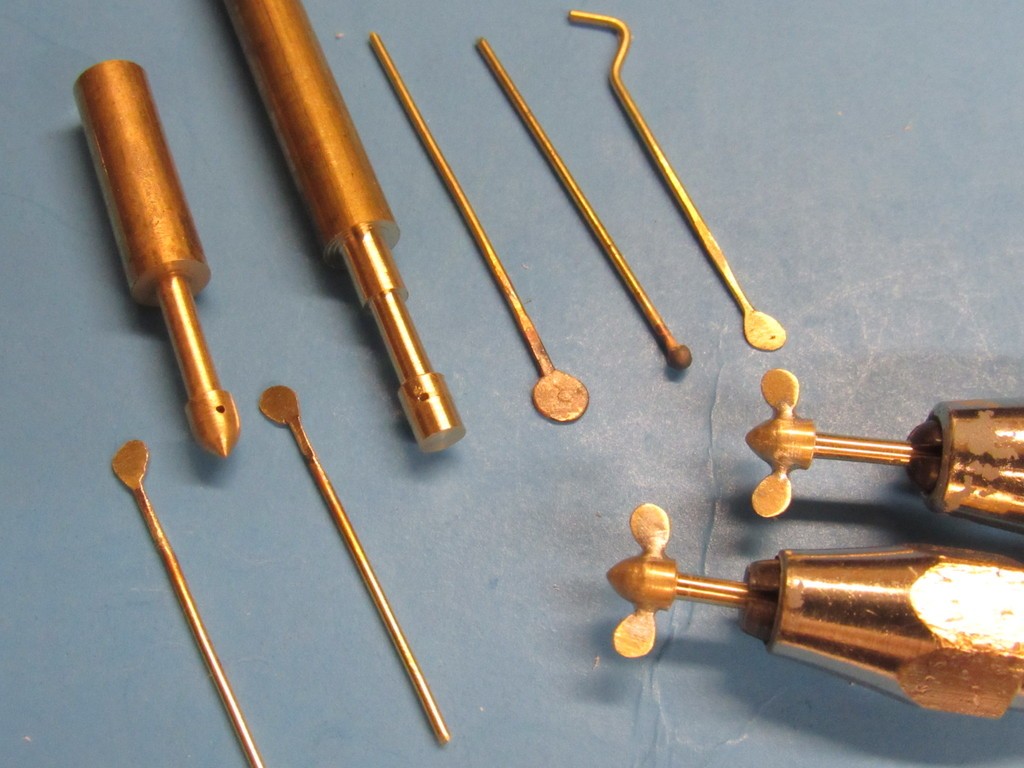

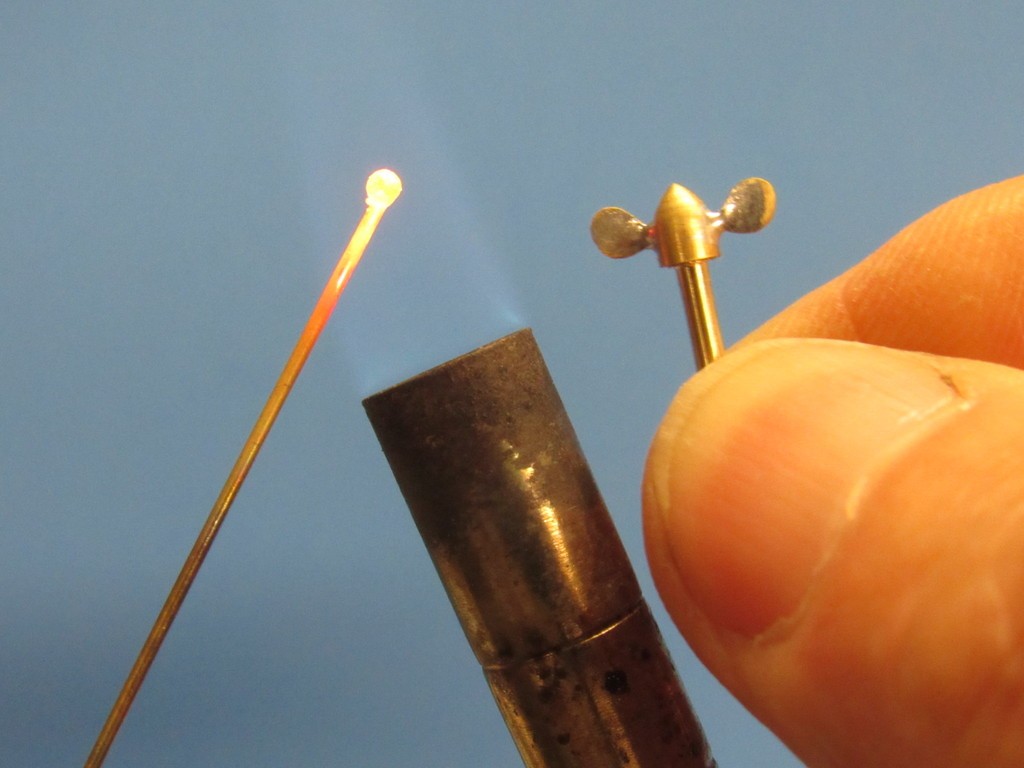

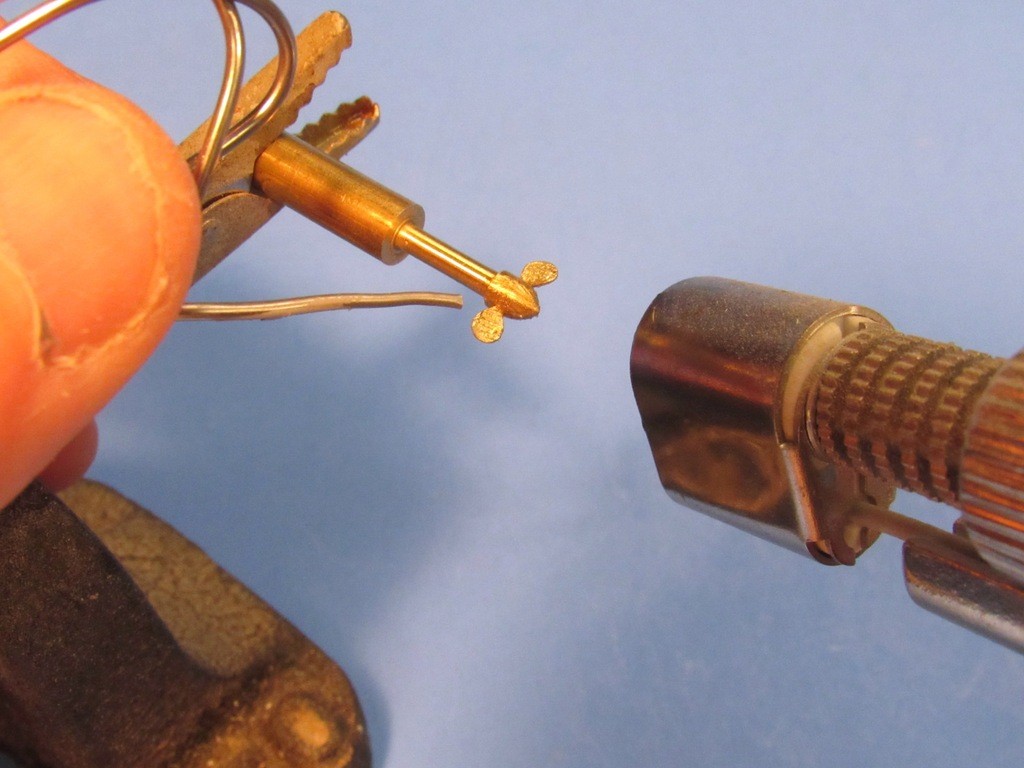

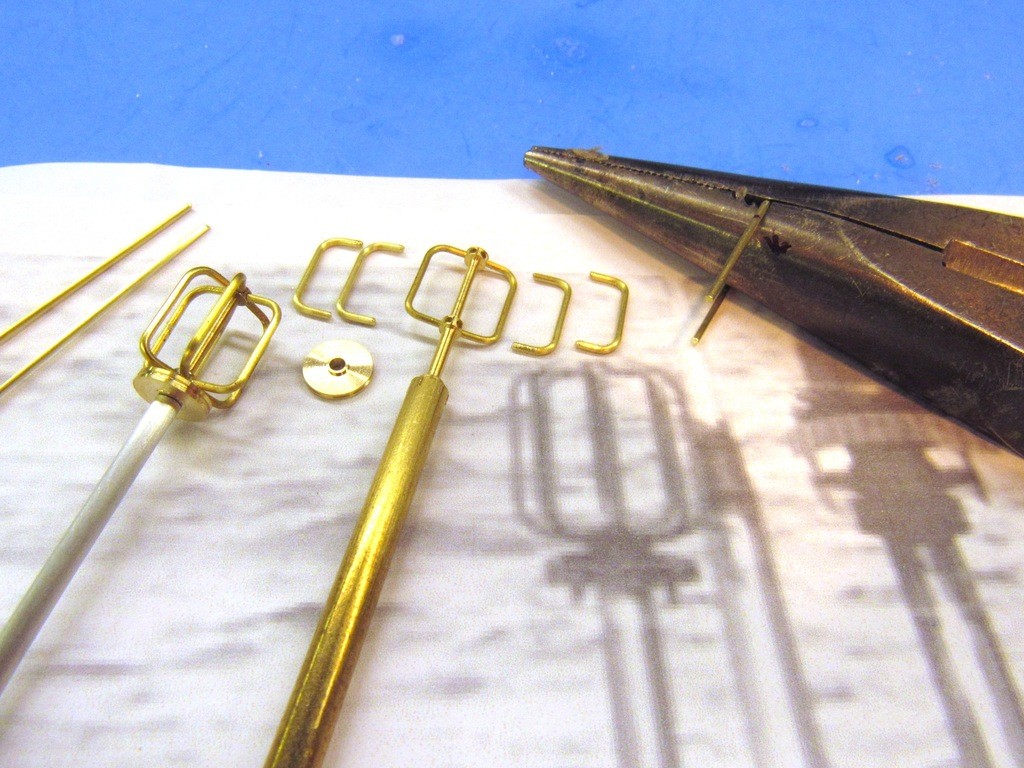

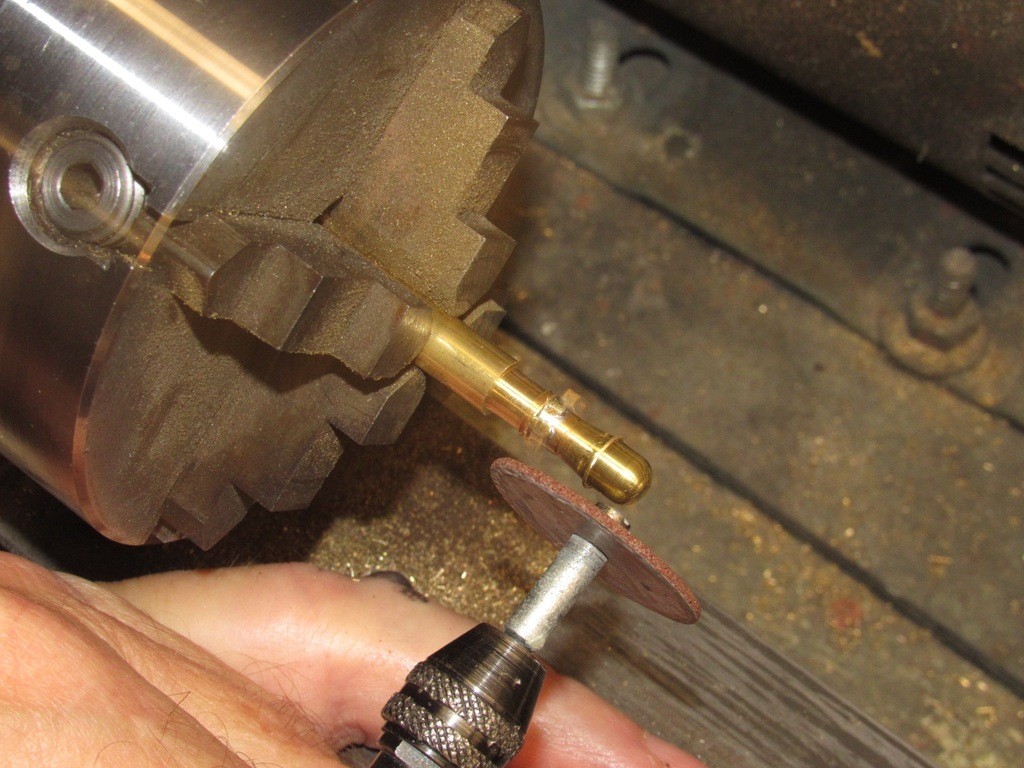

Current task is making the little outboard propellers – used for in-harbor maneuvering and possibly as a back-up to the main running gear should a propulsion casualty occur.

It has been suggested that these direct-drive, electric motor driven propulsors might also have been used for ‘silent running’ in some tactical situations, but I’ve yet to read a reliable source saying so. The ALFA’s liquid metal cooled reactor could never be shut down to the point where the coolant changed state, so they needed primary pumps running all the time if any useful power-level was to be maintained. Knowing this I just can’t imagine the logic of this class of boat ever running silent on those two creeper-motors -- might as well expect to hear a pin drop at a KISS concert.

» Modulated electric fields for submarine communication in a "heads up" from Harry!

» 868/915 Mhz as a viable frequency for submarines.

» Laser cut Robbe U47 conversion

» ExpressLRS - 868/915 Mhz equipment

» Information on camouflage patterns for German seahund

» WW2 mini sub build

» Not the hobby I expected :)

» Sheerline gasket material