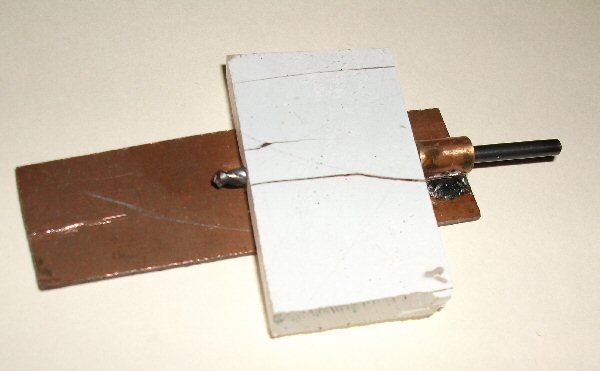

How the heck do I drill a hole through the width of this resin casting? It has to be perfectly level and square because it's for the dive vane operating shaft.

In total there are 4 users online :: 0 Registered, 0 Hidden and 4 Guests

None

Most users ever online was 180 on Tue Nov 05, 2019 6:03 am

Our users have posted a total of 12533 messages in 1992 subjects

We have 1019 registered users

The newest registered user is Flyboy21

Drilling a vertical hole

Drilling a vertical hole

Re: Drilling a vertical hole

Re: Drilling a vertical hole

Re: Drilling a vertical hole

Re: Drilling a vertical hole Re: Drilling a vertical hole

Re: Drilling a vertical hole

Re: Drilling a vertical hole

Re: Drilling a vertical hole Re: Drilling a vertical hole

Re: Drilling a vertical hole

Re: Drilling a vertical hole

Re: Drilling a vertical hole

Re: Drilling a vertical hole

Re: Drilling a vertical hole

» WW2 mini sub build

» sonar data link

» Robbe Seawolf V2

» ExpressLRS - 868/915 Mhz equipment

» Flight controllers as sub levelers

» 868/915 Mhz as a viable frequency for submarines.

» Futaba -868/915mhz equipment

» Microgyro pitch controller corrosion